Preparation method of a core-shell magnetic surface imprinted nanocomposite material

A nanocomposite material and surface imprinting technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of uniform coating and thickness control of difficult-to-polymerize layers, and achieve excellent regeneration performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

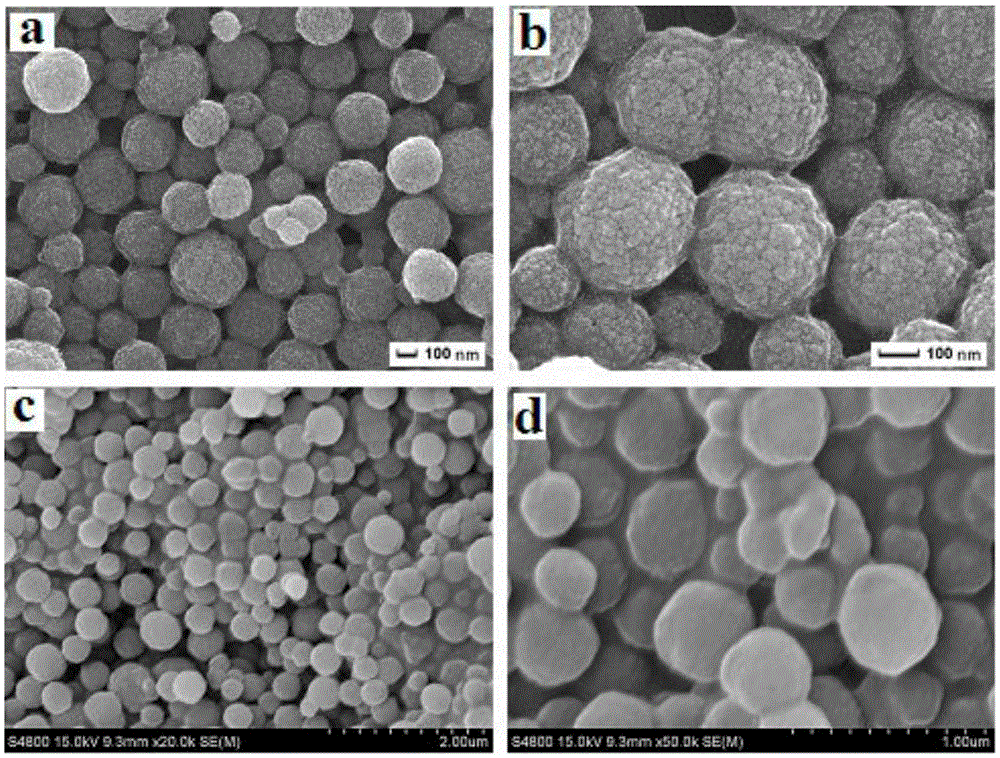

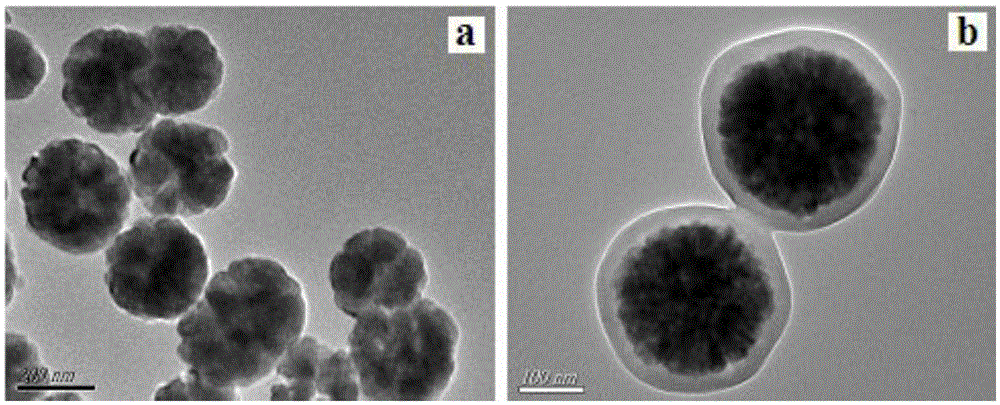

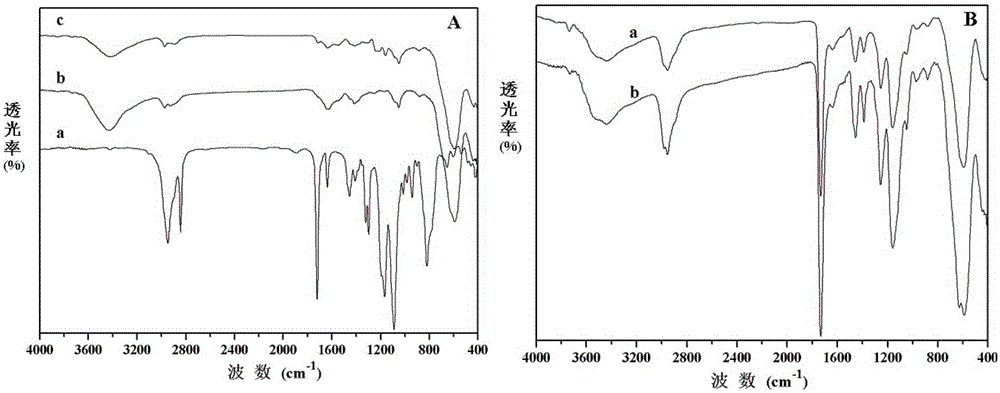

[0026] (1) Synthesis of ferric oxide nanospheres

[0027] Ferric chloride hexahydrate (FeCl 3 ·6H 2 (0), wherein the volume and mass ratio of ethylene glycol to ferric chloride hexahydrate is medium 40:1.0 (ml / g), vigorously stirred for 30min until a uniform solution is formed; in the above solution, add anhydrous sodium acetate (NaAc ) and polyethylene glycol (PEG-6000), wherein the mass ratio of anhydrous sodium acetate to polyethylene glycol is 3.0:0.5 (mg / mg) and stirred vigorously until completely dissolved, then moved into a stainless steel reaction kettle, at 150 o C under reaction 6.0h, after the reaction is completed, cool to room temperature, separate with rd-Fe-B permanent magnet, wash the product multiple times with absolute ethanol and deionized water, at 50 o C under vacuum drying, to obtain black magnetic ferric oxide nanospheres (Fe 3 o 4 ).

[0028] (2) Surface modification of Fe3O4 nanospheres

[0029] Add toluene, ferric oxide nanospheres and 3-(methac...

Embodiment 2

[0033] (1) Synthesis of ferric oxide nanospheres

[0034] Ferric chloride hexahydrate (FeCl 3 ·6H 2 (0), wherein the volume and mass ratio of ethylene glycol to ferric chloride hexahydrate is medium 40:1.5 (ml / g), vigorously stirred for 30min until a uniform solution is formed; in the above solution, add anhydrous sodium acetate (NaAc ) and polyethylene glycol (PEG-6000), wherein the mass ratio of anhydrous sodium acetate and polyethylene glycol is 4.0:1.5 and stirred vigorously until completely dissolved, then moved into a stainless steel reaction kettle, at 220 o C under reaction for 12h, after the completion of the reaction, cool to room temperature, separate with rd-Fe-B permanent magnet, wash the product multiple times with dehydrated ethanol and deionized water, at 60 o C under vacuum drying, to obtain black magnetic ferric oxide nanospheres (Fe 3 o 4 ).

[0035] (2) Surface modification of Fe3O4 nanospheres

[0036] Add toluene, ferric oxide nanospheres and 3-(met...

experiment example 1

[0043] Experimental Example 1: Take 10ml of tetracycline solutions with initial concentrations of 10, 30, 50, 80, 100, 150, and 200 μmol / L, respectively, and add them to centrifuge tubes, add 5.0 mg of MMIPs and MNIPs respectively, and put the test solution in a 298K water bath to statically After standing for 12.0 hours, the supernatant was collected by magnetic separation, and the concentration of unadsorbed tetracycline molecules was measured with an ultraviolet-visible spectrophotometer, and the adsorption capacity was calculated according to the results. Figure 7 The results showed that with the increase of temperature and concentration, the adsorption capacity increased gradually, and finally reached the adsorption equilibrium, and the adsorption capacity of MMIPs to tetracycline was always greater than that of MNIPs, which proved that there were a large number of imprinted pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com