an arsenic and so 3 Dry purification method of smelting flue gas

A smelting flue gas, dry technology, applied in the field of flue gas purification, can solve the problems of inability to effectively remove arsenic, difficult to realize resource utilization, difficult to separate adsorbents, etc., achieve efficient synergistic removal ability, improve enterprise economic benefits, The effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this example, a 10,000 m 3 / h flue gas, and set up a pilot flue gas purification device. The pilot plant is equipped with a cooling spray system, a cyclone dust collector, an adsorbent injection device, a fluidized bed reactor and a bag filter.

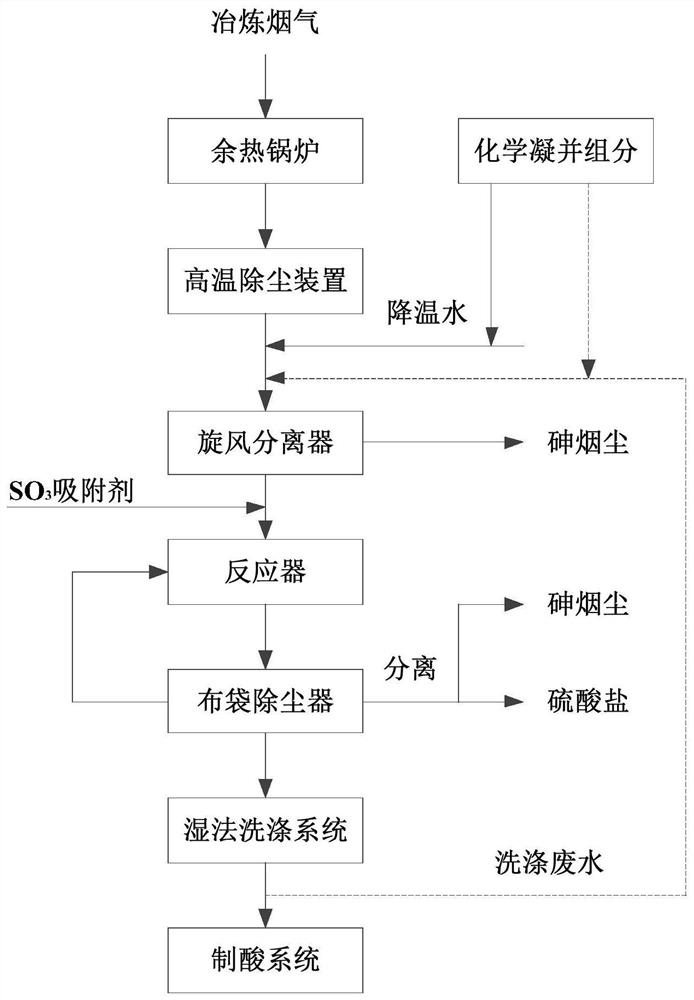

[0035] Arsenic and SO 3 The dry purification method of smelting flue gas, such as figure 1 shown, including the following steps:

[0036] (1) The cooling spray system uses a gas-liquid two-phase atomizing nozzle to spray a certain amount of cooling water and compressed air into the flue before the entrance of the cyclone dust collector to cool the flue gas temperature from 300°C to 170°C , so that the gaseous arsenic in the flue gas condenses into As 2 o3 Solid particles precipitated. At the same time, the flue gas temperature is close to SO 3 Acid dew point, partial SO 3 Exist in the form of sulfuric acid aerosol which is more easily captured by the adsorbent;

[0037] Among them, the flue gas in the flue comes from...

Embodiment 2

[0048] The present invention utilizes above-mentioned pilot plant to carry out effect verification. First, the temperature of the flue gas extracted is 300°C, and the As in the flue gas 2 o 3 The concentration is about 20mg / m 3 . Into the flue gas according to 6m 3 Spray cooling water into the flue at a speed of / min, and reduce the temperature of the flue gas to about 170°C before the cyclone inlet. As in flue gas after cyclone dust collector 2 o 3 Concentration decreased to 6mg / m 3 about. Further increase the injection speed of cooling water to 6.8L / min, and the flue gas temperature before the cyclone inlet will be as low as about 125°C. As in flue gas after cyclone dust collector 2 o 3 Concentration decreased to 3mg / m 3 about.

[0049] Adopt present embodiment method, total arsenic recovery rate is up to more than 98%, to SO 3 The removal rate can reach more than 98%.

Embodiment 3

[0051] The present invention utilizes above-mentioned pilot plant to carry out effect verification. First, the temperature of the flue gas extracted is 300°C, and the SO in the flue gas 3 The concentration is about 3000mg / m 3 . Spray calcium carbonate powder into the flue gas at a rate of 40kg / h into the flue in front of the fluidized bed reactor; the flue gas passes through the fluidized bed reactor and the bag filter in turn. SO in the flue gas at the outlet of the bag filter 3 The concentration is reduced to 1000mg / m 3 . Continue to increase the feeding rate of calcium carbonate powder to 80kg / h, then the flue gas SO at the outlet of the bag filter 3 Concentration reduced to 300mg / m 3 .

[0052] Adopt present embodiment method, total arsenic recovery rate is up to more than 99%, to SO 3 The removal rate can reach more than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com