Method for adsorbing uranyl ions

A technology of uranyl ions and adsorption materials, which is applied in the field of polymer material modification, can solve the problem of high cost of adsorption materials, and achieve the effects of high specific surface area, good mechanical properties and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

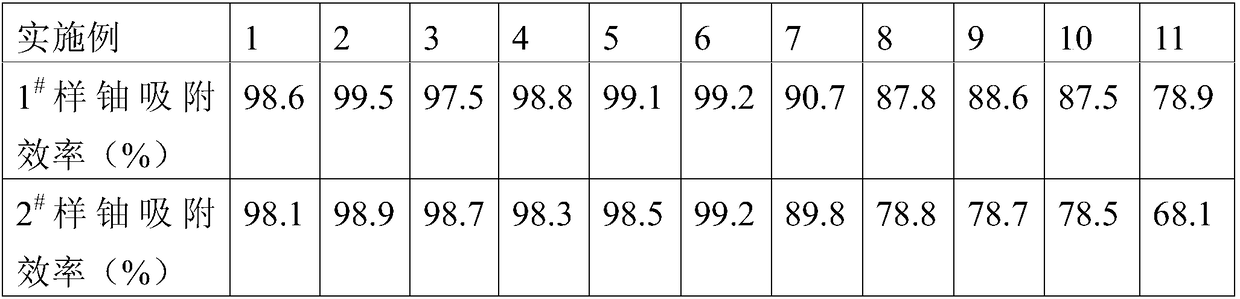

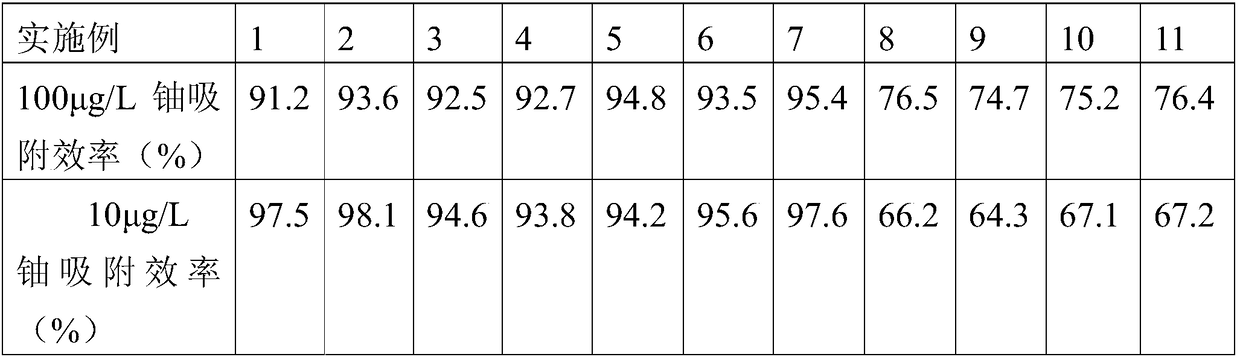

Examples

Embodiment 1

[0021] S1, in air, pre-irradiate ultra-high molecular weight polyethylene (UHMWPE) fibers with a cobalt source at room temperature, and the pre-irradiation dose is 60kGy;

[0022] S2, add 90 mL of distilled water and 18 mL of hydroxyethyl acrylate (HEA) into the Erlenmeyer flask, stir for 0.5 h to mix HEA and distilled water evenly. Add 1.5g of pre-irradiated UHMWPE fibers to it, blow nitrogen gas for 20min to remove oxygen, and seal it. The system was reacted in a water bath at 45°C for 2h. The grafted material was taken out, washed with distilled water, and put into an oven to dry for 24 hours. The grafting rate of the UHMWPE fibers with hydroxyl groups was calculated to be 80%.

[0023] S3, taking 0.8g of UHMWPE fibers with hydroxyl groups with a grafting rate of 80% and immersing them in the grafting solution prepared in advance, and reacting in a water bath at 30° C. for 6 hours under the protection of nitrogen. A total of 80 mL of the grafting solution was composed of...

Embodiment 2

[0026] S1, polyethylene-polypropylene skin-core structure (PE / PP) fibers were pre-irradiated with a cobalt source in air at room temperature, and the pre-irradiation dose was 15 kGy.

[0027] S2, add 90mL of distilled water and 18mL of HEA into the Erlenmeyer flask, stir for 0.5h to mix the HEA and distilled water evenly. Add 1.5g of pre-irradiated PE / PP fiber to it, blow nitrogen gas for 20min to remove oxygen, and seal it. The system was reacted in a water bath at 45°C for 2h. The grafted material was taken out, washed with distilled water, and put into an oven to dry for 24 hours. The graft ratio of the PE / PP fibers with hydroxyl groups was calculated by weighing method to be 20%.

[0028] S3, take 0.8g of PE / PP fibers with hydroxyl groups with a grafting rate of 20%, and immerse them in the grafting solution prepared in advance, and react in a water bath at 30° C. for 6 hours under the protection of nitrogen. A total of 80 mL of the grafting solution is composed of: AN5...

Embodiment 3

[0031] S1, in air, high-density polyethylene (HDPE) fibers were pre-irradiated with electron beams at room temperature, and the pre-irradiation dose was 70kGy.

[0032]S2, add 190 mL of distilled water and 10 mL of hydroxyethyl methacrylate (HEMA) into the Erlenmeyer flask, stir for 0.5 h to mix HEMA and distilled water evenly. Add 2.0 g of pre-irradiated HDPE fiber to it, blow nitrogen gas for 10 minutes to remove oxygen, and seal it. The system was reacted in a water bath at 35°C for 3h. The grafted material was taken out, washed with distilled water, and put into an oven to dry for 24 hours. The grafting rate of HDPE fibers with hydroxyl groups was calculated by weighing method to be 45%.

[0033] S3, taking 1.0 g of HDPE fibers with a grafting rate of 45% and immersing them in the grafting solution prepared in advance, and reacting in a water bath at 75° C. for 4 hours under the protection of nitrogen. A total of 120 mL of the grafting solution is composed of: 50 vol.% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com