A method for treating nitroaromatic hydrocarbons with a carbon nitride-supported nano-gold catalyst reduced by polydopamine

A technology of nitroaromatic hydrocarbons and polydopamine, which is applied in the direction of reducing water/sewage treatment, physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, etc. Ideal and other problems, to achieve the effect of short active hydrogen transfer distance, good electron transfer ability and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method utilizing polydopamine-reduced carbon nitride-loaded nano-gold catalysts to process nitroaromatic substances, comprising the following steps:

[0058] Use deionized water to prepare p-nitrophenol solution A with a concentration of 0.02mM. The solution A is light yellow, and its ultraviolet spectrum is measured. Take 1.5mL of the prepared A solution and add freshly prepared NaBH with a concentration of 8mM 4 Solution B 1.5mL, the solution was light yellow-green after being fully mixed, and its ultraviolet spectrum was measured. 10 mg of the prepared polydopamine-reduced carbon nitride supported nano-gold catalyst was added to the mixed solution of A and B prepared above, and its ultraviolet spectrum was measured with an ultraviolet spectrophotometer at different reaction times.

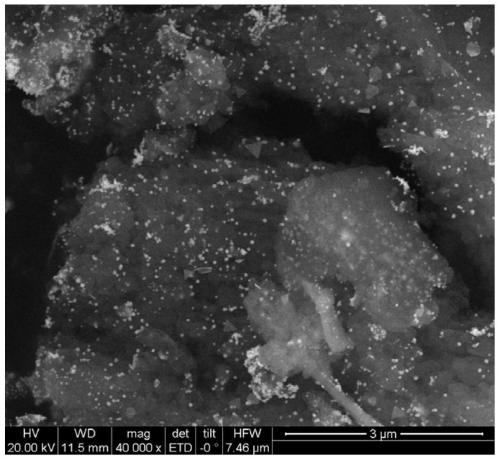

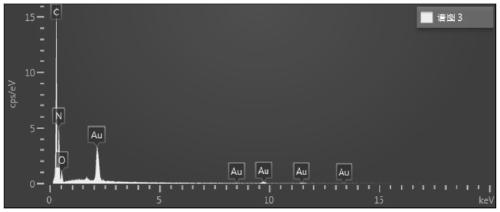

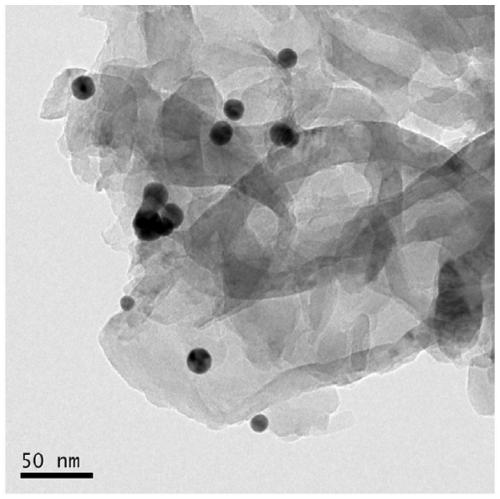

[0059] The above-mentioned polydopamine-reduced carbon nitride-supported nano-gold catalyst, nano-gold and PDA-g-C 3 N 4 The mass ratio of the carrier is 3:30, the mass ratio of poly...

Embodiment 2

[0070] A method utilizing polydopamine-reduced carbon nitride-loaded nano-gold catalysts to process nitroaromatic substances, comprising the following steps:

[0071] Use deionized water to prepare p-nitrophenol solution A with a concentration of 0.02mM. The solution A is light yellow, and its ultraviolet spectrum is measured. Take 1.5mL of the prepared A solution and add freshly prepared NaBH with a concentration of 8mM 4 Solution B 1.5mL, the solution was light yellow-green after being fully mixed, and its ultraviolet spectrum was measured. Take the prepared carbon nitride-loaded nano-gold catalyst 10 mg of polydopamine reduction of different nano-gold loads, add it to the mixed solution of A and B prepared above, and measure its ultraviolet ray with a UV spectrophotometer at different reaction times. spectroscopic spectrum.

[0072] The above-mentioned polydopamine-reduced carbon nitride-supported nano-gold catalyst, nano-gold and PDA-g-C 3 N 4 The mass ratio of the car...

Embodiment 3

[0079] A method utilizing polydopamine-reduced carbon nitride-loaded nano-gold catalysts to process nitroaromatic substances, comprising the following steps:

[0080] Use deionized water to prepare 0.02mM p-nitrophenol, 0.02mM 2,4-nitrophenol and 0.02mM methyl orange solutions, respectively take 1.5mL of the prepared solutions, and add freshly prepared concentrations 8mM NaBH 4 Solution 1.5mL, after mixing thoroughly, measure its ultraviolet spectrum. Take 10 mg of the polydopamine-reduced carbon nitride-loaded nano-gold catalyst prepared in Example 1, add it to the mixed solution prepared above, and measure its ultraviolet spectrum with an ultraviolet spectrophotometer at different reaction times.

[0081] Figure 5 For PDA-g-C in Example 3 of the present invention 3 N 4 / Au (9) Degradation effects of catalysts on p-nitrophenol, 2,4-nitrophenol and methyl orange (Ln(C t / C 0 )~t curve). Depend on Figure 5 It can be seen that the supported nano-gold catalyst prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com