Brass fitting laser welding method

A brass fittings, laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as increasing processing difficulty and increasing processes, and achieve beautifying the appearance of welds, improving production efficiency, and good performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

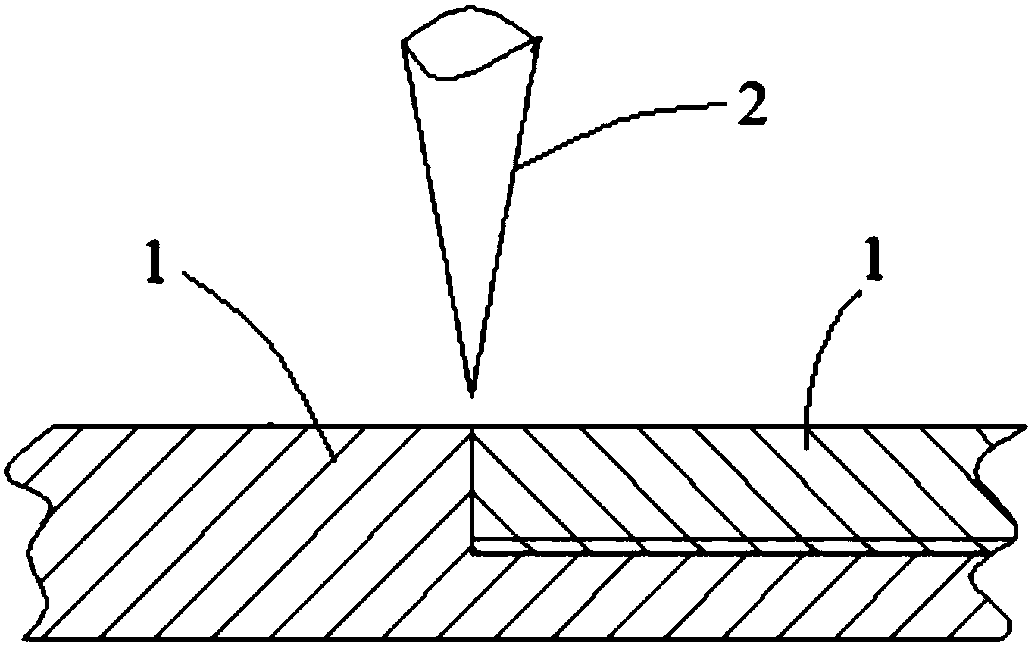

[0032] Such as Figure 1-Figure 3 , an embodiment of the present invention provides a laser welding method for brass fittings, including:

[0033] Step 1, cleaning the surfaces to be welded of the two brass weldments 1;

[0034] Step 2, positioning two brass weldments 1;

[0035] Step 3: Carry out laser rooting welding, wherein the spot diameter at the focal point is 0.2-0.5mm, the laser power is 600-1500W, the welding speed is 6-15mm / s, the defocus amount is -3-+3mm, and the gas shielded welding method is adopted;

[0036] Step 4: Carry out laser capping welding, wherein the spot diameter at the focal point is 0.2-0.5mm, the laser power is 600-1500W, the welding speed is 6-15mm / s, the defocus amount is +4-+15mm, and the gas shielded welding method is adopted.

[0037] In this embodiment, laser welding of brass fittings is realized by combining laser bottom welding and laser cover welding. Through reasonable selection of process parameters in the two welding processes, welds...

Embodiment 2

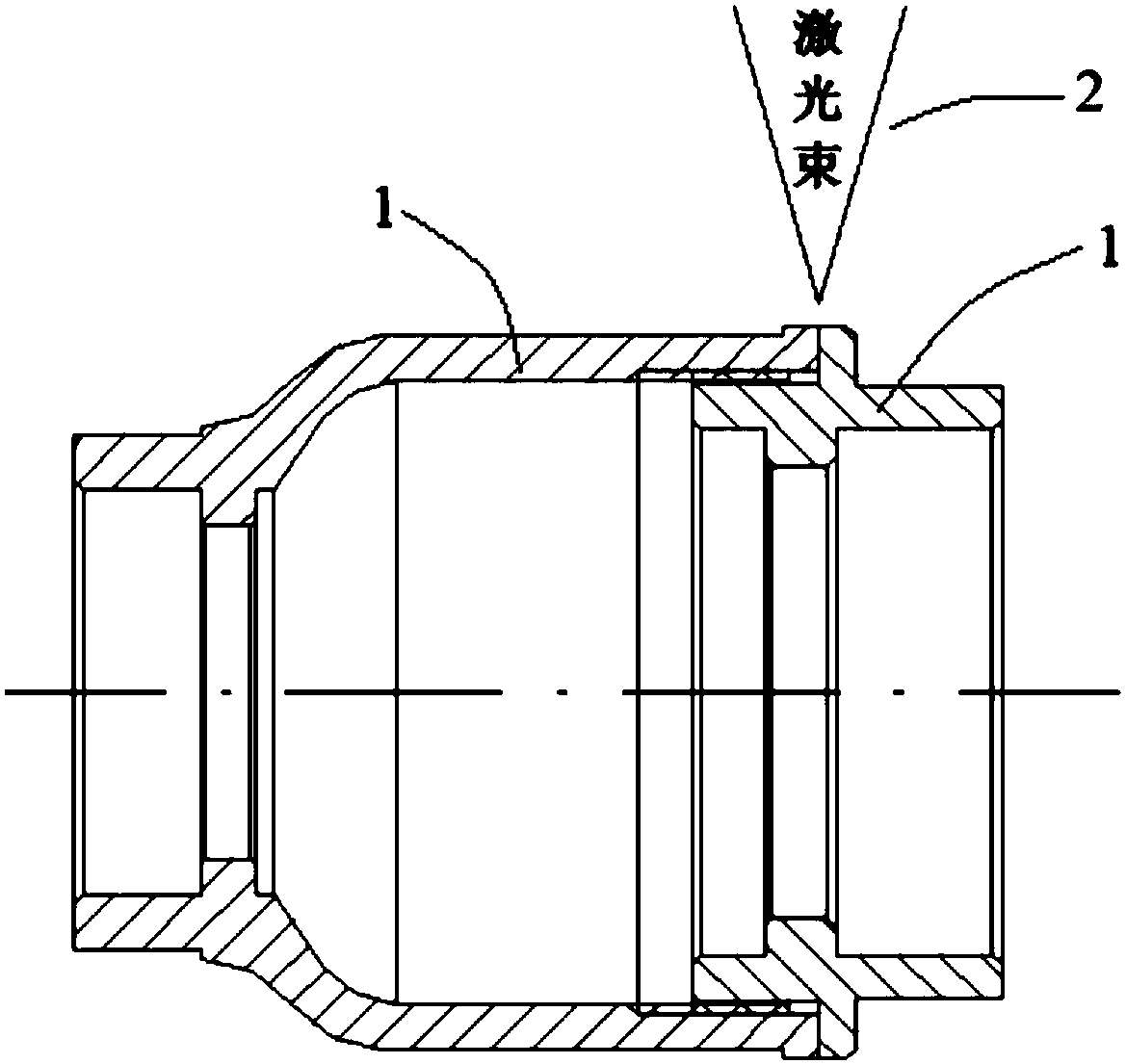

[0049] Such as figure 2 , the brass fittings are valves used to control fluid flow, and the sum of the penetration depths of laser bottom welding and laser cap welding is controlled to be 1.8-2.5mm, and more preferably controlled at 2mm. Correspondingly,

[0050] In step 3, the diameter of the spot at the focus of the laser beam 2 is 0.3mm, the laser power is 780-850W, the welding speed is 9-12mm / s, and the defocus is 0, that is, the focus of the laser beam 2 is located on the surface of the two brass weldments 1 ; Wherein, as a preferred embodiment, the laser power is 800W, the welding speed is 10mm / s, and the laser power adopts a slow-rising and slow-falling control mode;

[0051] In step 4, the diameter of the spot at the focal point is 0.3mm, the laser power is 780-850W, the welding speed is 9-12mm / s, and the defocus is +6-+8mm; among them, as a preferred embodiment, the laser power is 800W, The welding speed is 10mm / s, the defocus is +7mm, and the laser power is control...

Embodiment 3

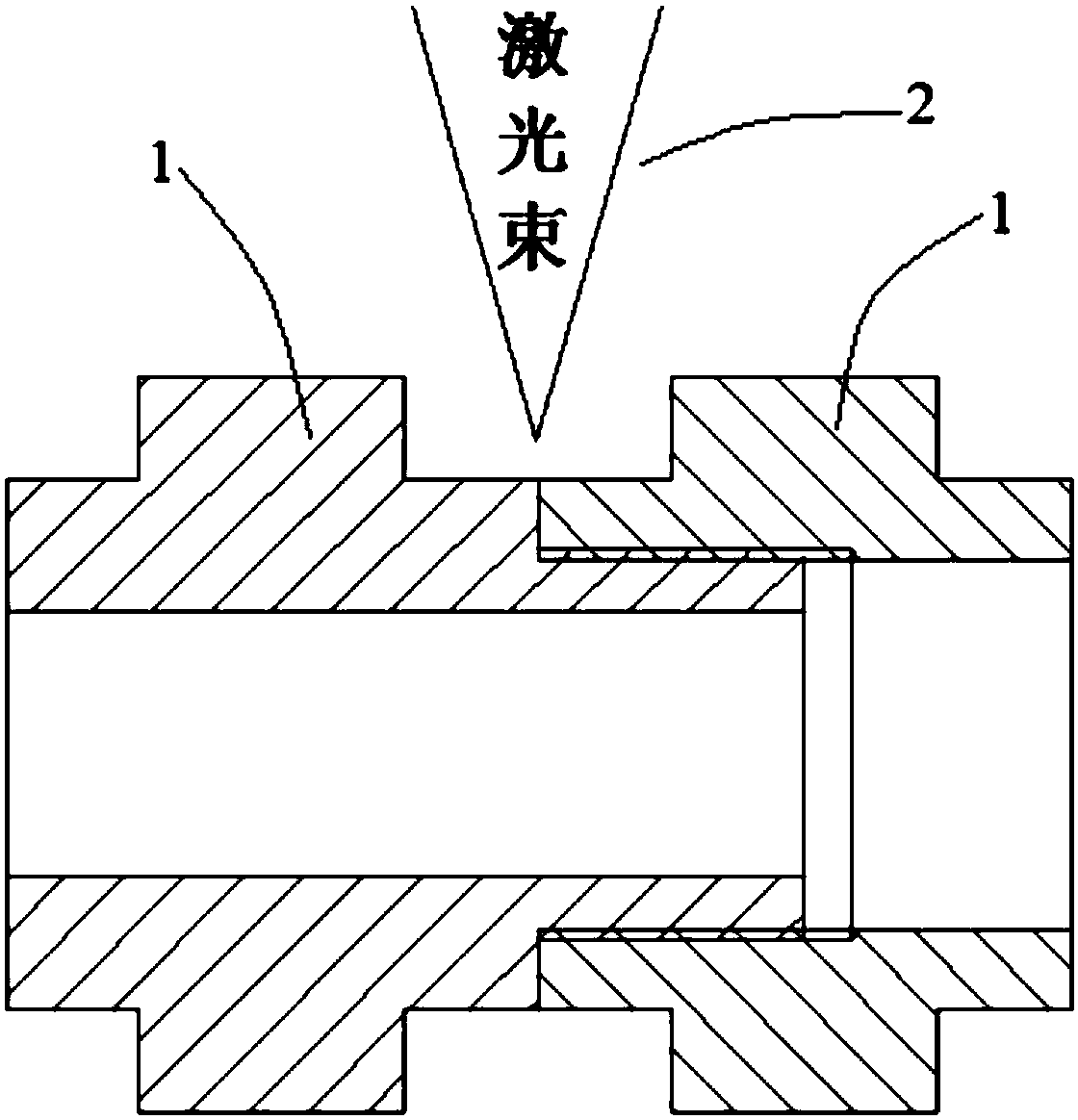

[0057] Such as image 3 , the brass accessories are refrigeration accessories, and the refrigeration accessories include air-conditioning refrigeration check valves, charging valves, liquid filling valves or needle valves. 1.2mm, further preferably controlled at 1mm, correspondingly,

[0058] In step 3, the diameter of the spot at the focal point of the laser beam 2 is 0.2mm, the laser power is 600-650W, the welding speed is 7-8mm / s, and the defocus is +2-+3mm; among them, as a preferred embodiment, the laser The power is 600W, the welding speed is 8mm / s, the defocus is +3mm, and the laser power adopts a slow-rising and slow-falling control method;

[0059] In step 4, the diameter of the spot at the focal point is 0.2mm, the laser power is 600-650W, the welding speed is 9-10mm / s, and the defocus is +5-+6mm; among them, as a preferred embodiment, the laser power is 600W, The welding speed is 10mm / s, the defocus amount is +5mm, and the laser power adopts a slow-rising and slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com