Mortar shortening coagulation time and preparation method thereof

A technology of setting time and mortar, applied in the field of mortar, can solve the problems of inconvenient construction, delaying the construction process, long setting time of mortar, etc., and achieve the effect of reducing setting time, improving work efficiency and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

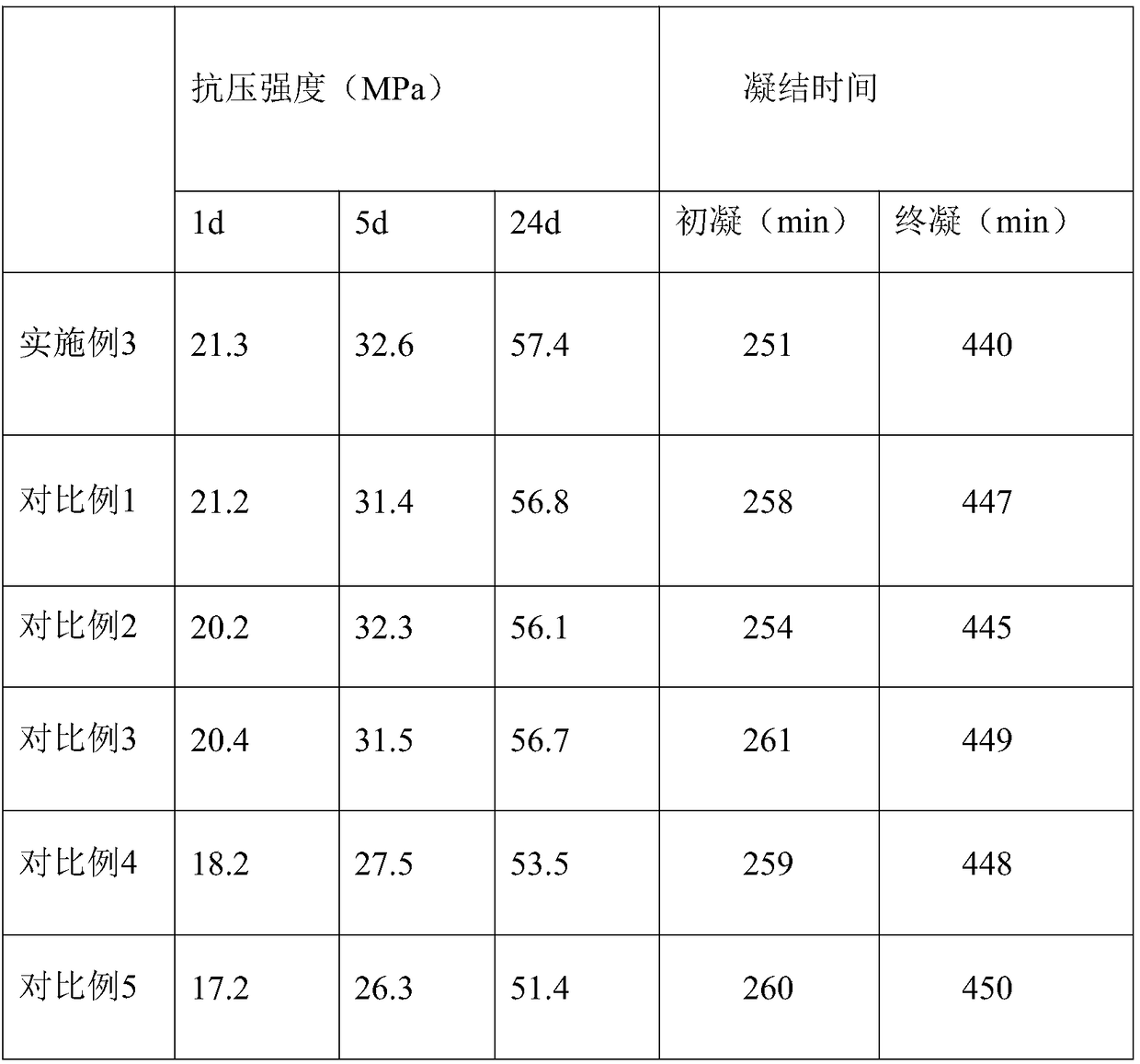

Examples

Embodiment 1

[0030] A kind of mortar that can shorten setting time of the present embodiment comprises the raw material of following weight portion:

[0031] 38 parts of Portland cement, 34 parts of quartz sand, 18 parts of latex powder, 18 parts of cellulose diacetate, 16 parts of sodium bentonite treated with calcium chloride, 6 parts of polyacrylamide, 4 parts of coagulation aid, aluminum sulfate mixed Miscellaneous fly ash 2 parts.

[0032] The preparation method of calcium chloride-treated sodium-based bentonite in this embodiment is to grind the sodium-based bentonite, pass through a 20-mesh sieve, and then add it to a calcium chloride solution with a mass fraction of 92%, and mix and stir at a stirring speed of 155 r / min , followed by suction filtration, sent to an oven for drying, and then ground to powder, that is, calcium chloride-treated sodium-based bentonite.

[0033] The mass ratio of calcium chloride and sodium bentonite in this embodiment is 3:10.

[0034] The coagulation...

Embodiment 2

[0044] A kind of mortar that can shorten setting time of the present embodiment comprises the raw material of following weight portion:

[0045] 44 parts of Portland cement, 34 parts of quartz sand, 24 parts of latex powder, 22 parts of cellulose diacetate, 20 parts of sodium bentonite treated with calcium chloride, 10 parts of polyacrylamide, 10 parts of coagulation aid, aluminum sulfate mixed Miscellaneous fly ash 5 parts.

[0046] The preparation method of the calcium chloride-treated sodium-based bentonite in this embodiment is to grind the sodium-based bentonite, pass through a 20-mesh sieve, and then add it to a calcium chloride solution with a mass fraction of 96%, and mix and stir at a stirring speed of 175r / min , followed by suction filtration, sent to an oven for drying, and then ground to powder, that is, calcium chloride-treated sodium-based bentonite.

[0047] The mass ratio of calcium chloride and sodium bentonite in this embodiment is 3:10.

[0048] The coagul...

Embodiment 3

[0058] A kind of mortar that can shorten setting time of the present embodiment comprises the raw material of following weight portion:

[0059] 41 parts of Portland cement, 32 parts of quartz sand, 21 parts of latex powder, 20 parts of cellulose diacetate, 18 parts of sodium bentonite treated with calcium chloride, 8 parts of polyacrylamide, 7 parts of coagulation aid, aluminum sulfate mixed Miscellaneous fly ash 3.5 parts.

[0060] The preparation method of calcium chloride-treated sodium-based bentonite in this embodiment is to grind the sodium-based bentonite, pass through a 20-mesh sieve, and then add it to a calcium chloride solution with a mass fraction of 94%, and mix and stir at a stirring speed of 160r / min , followed by suction filtration, sent to an oven for drying, and then ground to powder, that is, calcium chloride-treated sodium-based bentonite.

[0061] The mass ratio of calcium chloride and sodium bentonite in this embodiment is 3:10.

[0062] The coagulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com