Special organic fertilizer for camellia oleifera and preparation method thereof

A technology of organic fertilizer and camellia oleifera, which is applied in the field of special organic fertilizer for camellia oleifera and its preparation, can solve the problems of unfavorable specificity, unfavorable growth of camellia oleifera, high production cost, etc., and achieve the goals of reducing the content of impurities, shortening the decomposing time, and accelerating the decomposition speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

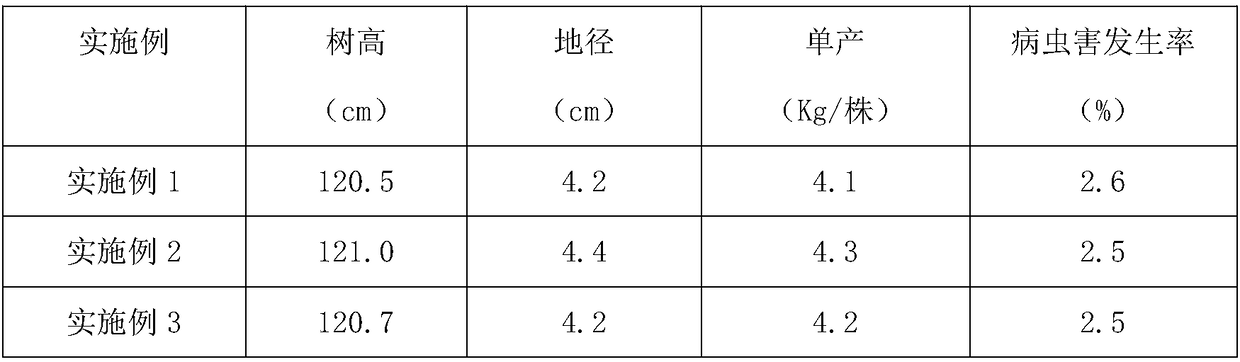

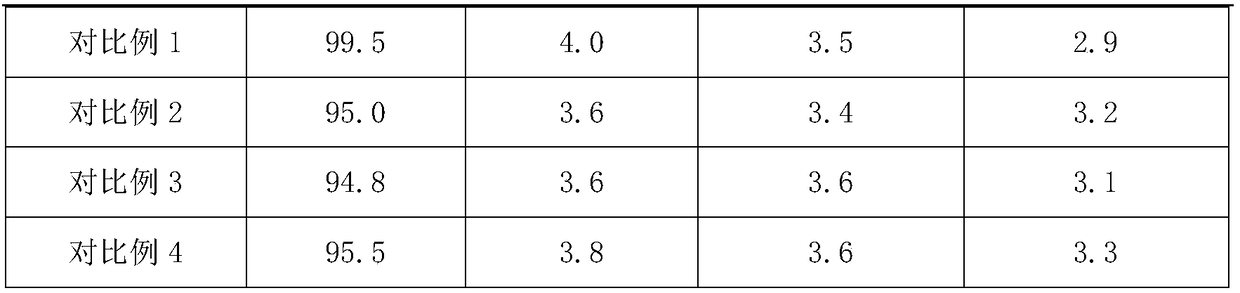

Examples

Embodiment 1

[0031] 1) Crush the dead branches and leaves of Camellia oleifera for later use, and mix 45 parts of dead branches and leaves of Camellia oleifera and 47 parts of kitchen waste according to the following parts by weight to obtain a mixture. The carbon to nitrogen ratio of the mixture is 26:1;

[0032] 2) Weigh 2 parts of carboxymethyl cellulose grafted acrylic acid, 0.2 parts of EM bacterial agent and 0.5 parts of brown sugar into the above mix

[0033] 3) In the material, add water and stir evenly, gather it into a fermentation pile, the moisture content of the raw materials in the fermentation pile is 65-70%; the surface of the fermentation pile is covered with black plastic film, anaerobic fermentation, and timely add water to add moisture to make the raw material moisture content Maintained at 65-70%, and the compost is fermented for 15-40 days until the temperature in the fermenting pile no longer rises, and a semi-rotted material is obtained;

[0034] 4) Add 2 parts of earthwor...

Embodiment 2

[0036] 1) Crush the dead branches and leaves of Camellia oleifera for use, and mix 47 parts of dead branches and leaves of Camellia oleifera and 45 parts of kitchen waste uniformly according to the following parts by weight to obtain a mixture. The carbon to nitrogen ratio of the mixture is 28:1;

[0037] 2) Weigh 3 parts of polyacrylamide, 0.1 part of EM bacterial agent and 0.3 part of brown sugar into the above mixture, add water and stir evenly, gather it into a fermentation pile, the water content of the raw materials in the fermentation pile is 65-70%;

[0038] 3) The surface of the fermentation pile is covered with black plastic film, anaerobic fermentation is added, and water is added in time to replenish water, so that the moisture content of the raw materials is maintained at 65-70%, and the compost is fermented for 5-20 days until the temperature in the fermentation pile no longer rises. Get half rot

[0039] 4) Add 1.4 parts of earthworms and 3 parts of kitchen waste to th...

Embodiment 3

[0041] 1) Crush the dead branches and leaves of Camellia oleifera for use, and mix 50 parts of dead branches and leaves of Camellia oleifera and 40 parts of kitchen waste uniformly according to the following parts by weight to obtain a mixture. The carbon-nitrogen ratio of the mixture is 30:1;

[0042] 2) Weigh 3 parts of polyvinyl alcohol, 0.1 part of EM microbial agent and 0.5 part of brown sugar into the above mixture, add water and stir evenly, gather it into a fermentation pile, the water content of the raw materials in the fermentation pile is 65-70%;

[0043] 3) The surface of the fermentation pile is covered with black plastic film, anaerobic fermentation is added, and water is added to supplement moisture in time to maintain the moisture content of the raw materials at 65-70%, and the compost is fermented for 15-40 days until the temperature in the fermentation pile no longer rises. Get half rot

[0044] 4) Add 1 part of earthworm and 5 parts of kitchen waste to the semi-rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com