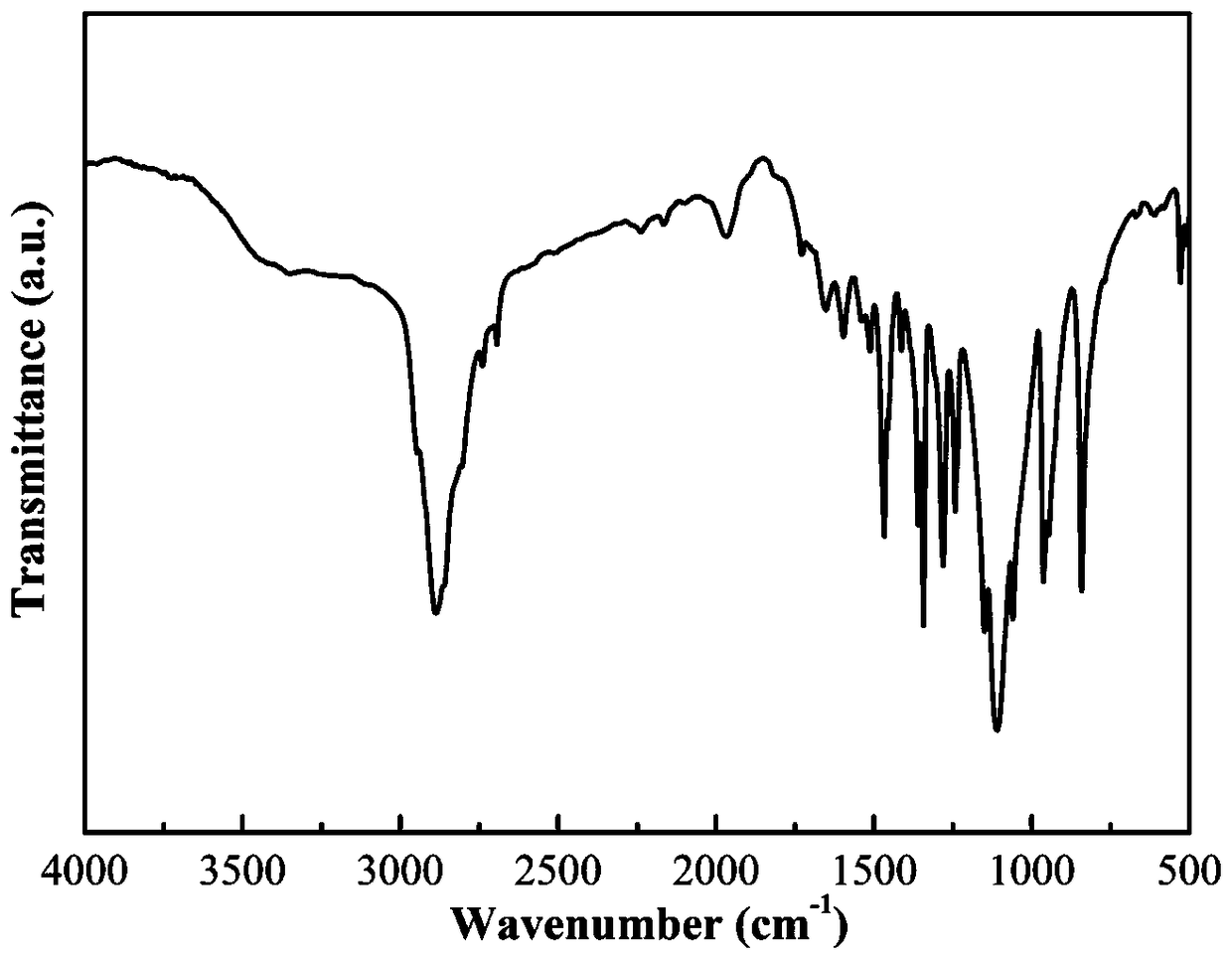

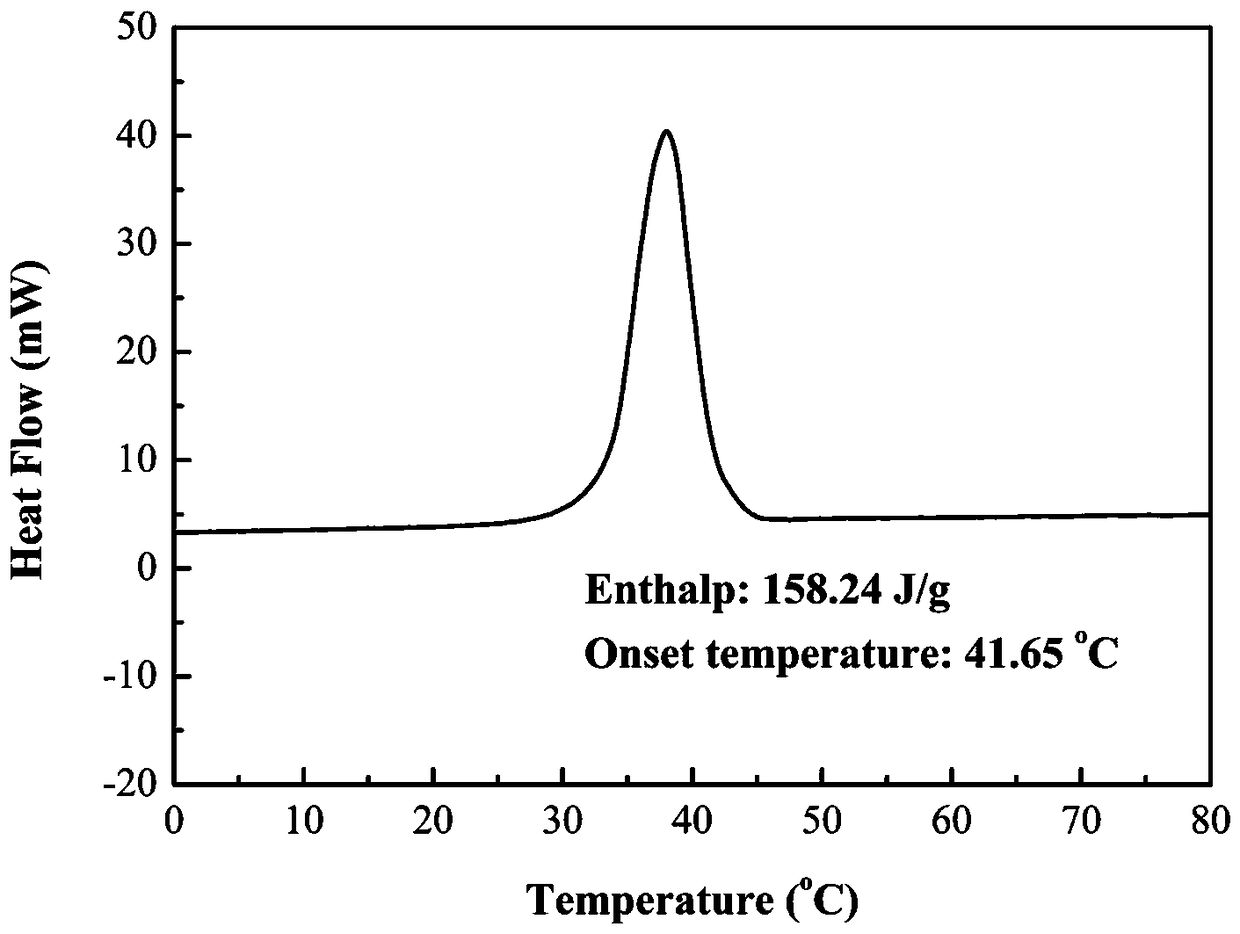

Polyethylene glycol grafted graphene oxide composite solid-solid phase change material and preparation method thereof

A technology of polyethylene glycol grafting and graphene compounding, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of low latent heat of phase change, poor high thermal performance, etc., and achieve improved heat transfer performance and thermal conductivity Excellent, compatibility-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Step 1) Use a cross-linking agent to carry out terminal functional modification of polyethylene glycol,

[0026] Weigh 10 g of polyethylene glycol with a weight-average molecular weight of 8000 and place it in a three-necked flask, add 50 mL of N,N-dimethylformamide (DMF) solution, heat to 85 °C, and magnetically stir until it is completely dissolved to obtain poly Ethylene glycol-DMF solution. Weigh 4,4'-diphenylmethane diisocyanate (MDI) with a ratio of 2:1 to polyethylene glycol, and dissolve it in 20 mL N,N-dimethylformamide (DMF) solution to obtain Crosslinker-DMF solution. The cross-linking agent-DMF solution was slowly added to the polyethylene glycol-DMF solution under magnetic stirring, and reacted at 85 ° C for 5 hours under an argon atmosphere to obtain a prepolymer;

[0027] Step 2) Add graphene oxide self-assembly and graft polymerization polyethylene glycol,

[0028] Weigh 0.9g of graphene oxide and add 100 mL of N,N-dimethylformamide (DMF) solution, pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com