Preparation method of noble metal nanoparticle-cellulose hybrid membrane

A cellulose and hybrid membrane technology, which is applied in the field of preparation of nano-precious metal particles-regenerated cellulose hybrid membrane, can solve the problems of uneven shape, difficulty in realizing industrialized production, and difficulty in controlling dispersion, and achieves a simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

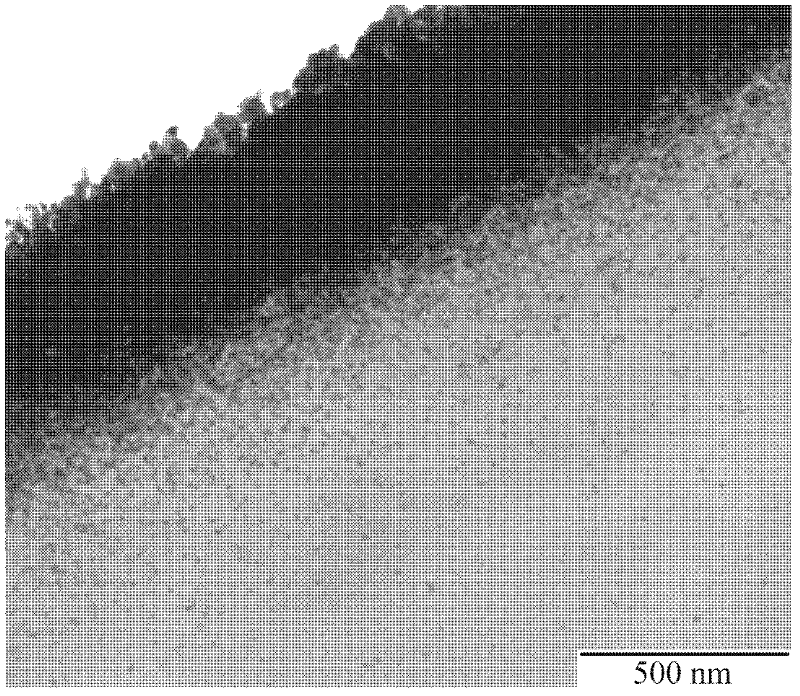

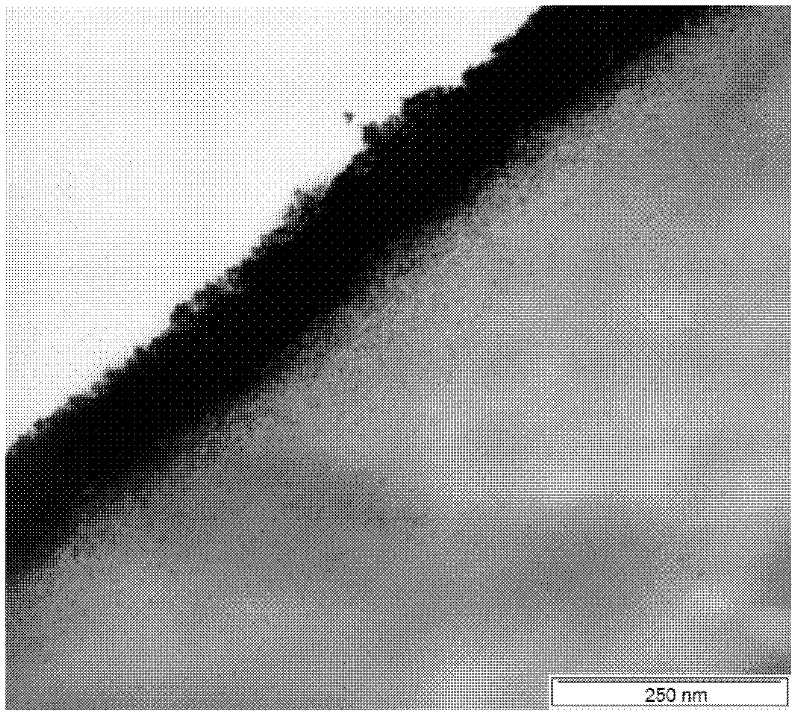

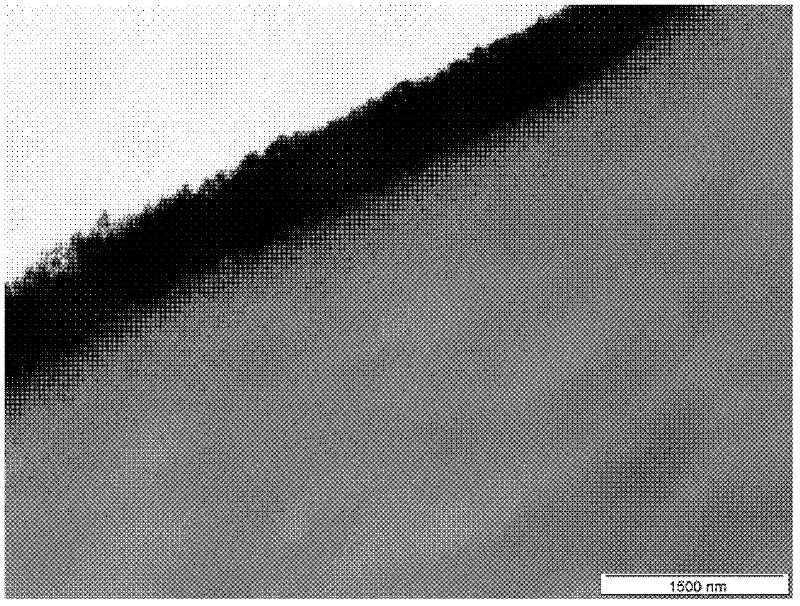

Image

Examples

Embodiment 1

[0031]At 90°C under the protection of nitrogen, add 2g of α-cellulose to 98g of NMMO H2O, and continue stirring for 2 hours to obtain a cellulose solution; The smooth silicate glass sheet is used as the substrate, and the cellulose solution dissolved at 70°C is used to spin the film on the surface of the spin coating machine to prepare the cellulose solution film, and the rotation speed is set at 1krpm; the cellulose is soaked in deionized water After the solution was smeared for 2 hours, the regenerated cellulose membrane was rinsed and stored in deionized water; 1.5 g of chloroauric acid (HAuCl 4 ) was dissolved in 4.5L deionized water, and the chloroauric acid solution was heated to boiling under magnetic stirring, and 4.5g sodium citrate (Na 3 C 6 h 5 o 7 ) was dissolved in 0.5L deionized water, and after dissolving, the sodium citrate solution was quickly added to the boiling chloroauric acid solution, and the heating was continued for 25 minutes, then the heating was ...

Embodiment 2

[0033] At 90°C under nitrogen protection, 8 g of cotton pulp cellulose and 0.05 g of propyl gallate were added to 92 g of NMMO·H 2 In O, after 24 hours of continuous stirring, a cellulose solution was obtained; under the conditions of a temperature of 30° C. and a relative humidity RH=30%, the cellulose solution dissolved at 90° C. was extruded and blown into a film by a film blowing machine, and passed The cellulose is regenerated by the sink, and the regenerated cellulose film is fully rinsed with water vapor; the 56g potassium chloroplatinate (K 2 PtCl 6 ) was dissolved in 57.6L deionized water, and the potassium chloroplatinate solution was heated to boiling under magnetic stirring; 98.4g citric acid (H 3 C 6 h 5 o 7 ) was dissolved in 6.4L deionized water, and after being fully dissolved, the sodium citrate solution was quickly added to the boiling potassium chloroplatinate solution, and the heating was continued for 25 minutes, then the heating was stopped, and the p...

Embodiment 3

[0035] At 90°C under nitrogen protection, 8 g of straw pulp cellulose was added to 32 g of NMMO·H 2 O, after continuous stirring for 12 hours, a cellulose solution was obtained, 80 g of DMSO was added thereto, and at 70° C., continued stirring for 12 hours to obtain a uniformly mixed film-forming liquid; Under certain conditions, after the film-forming solution at 75°C was left to stand for 20 minutes, the mica sheet was used as the base, and the clean substrate was dipped-pulled to form a film at a pulling speed of 15cm / min; use excess deionized water to soak the smear 2 hours, then fully rinse the regenerated cellulose membrane; at room temperature, 1.2g silver nitrate (AgNO 3 ) was dissolved in 14.4L deionized water, fully dissolved under medium-speed stirring; 3.9g potassium citrate (K 3 C 6 h 5 o 7 ) was dissolved in 1.6L deionized water, and after being fully dissolved, the potassium citrate solution was quickly added to the silver nitrate solution; after stirring co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com