Porous carbon fiber loading transition metal oxide, biosensor and preparing method of porous carbon fiber loading transition metal oxide

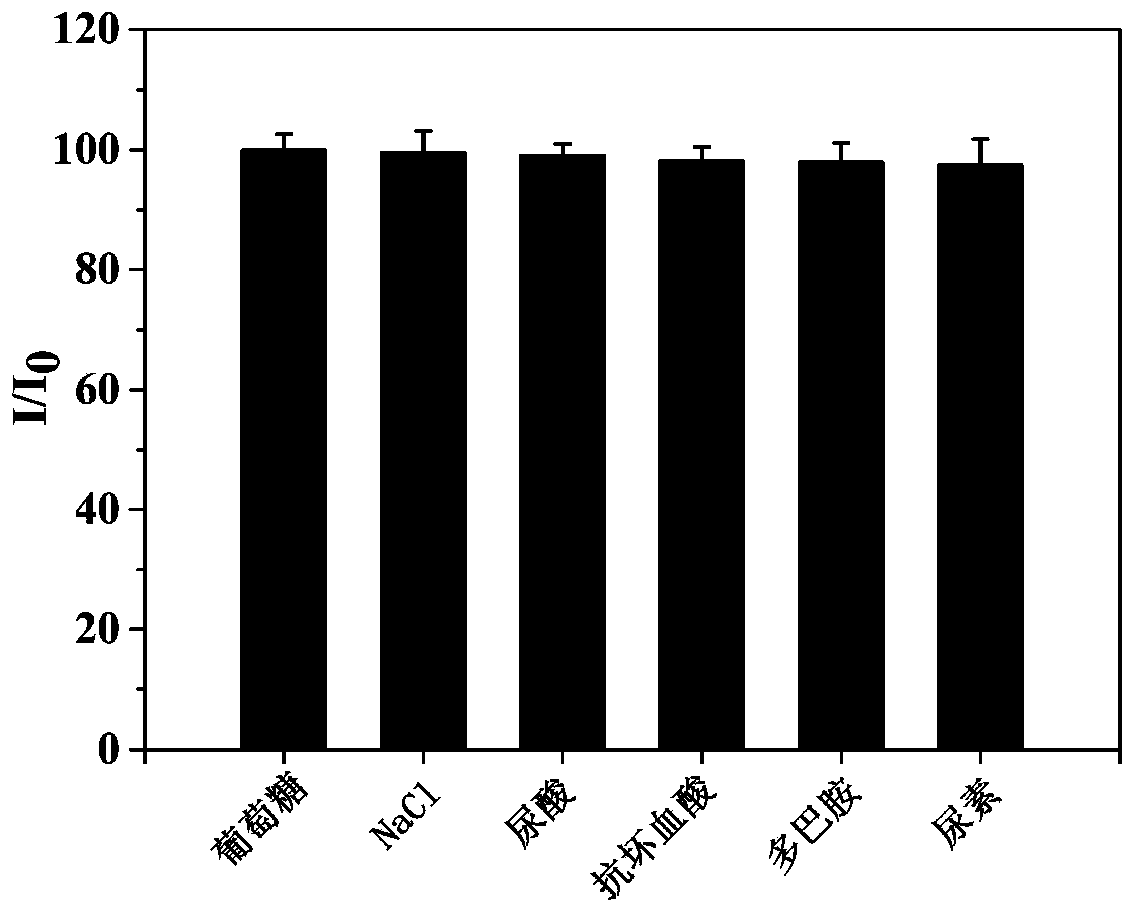

A porous carbon fiber and biosensor technology, applied in the field of biosensors, can solve the problems of cumbersome and complicated pore-forming process, unrecoverable pore-forming agent, and difficult control of pore structure, so as to improve the response signal of electrocatalytic reaction and electrochemical sensing Effects of performance, ability to facilitate charge transport, and specific selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of precursor fiber

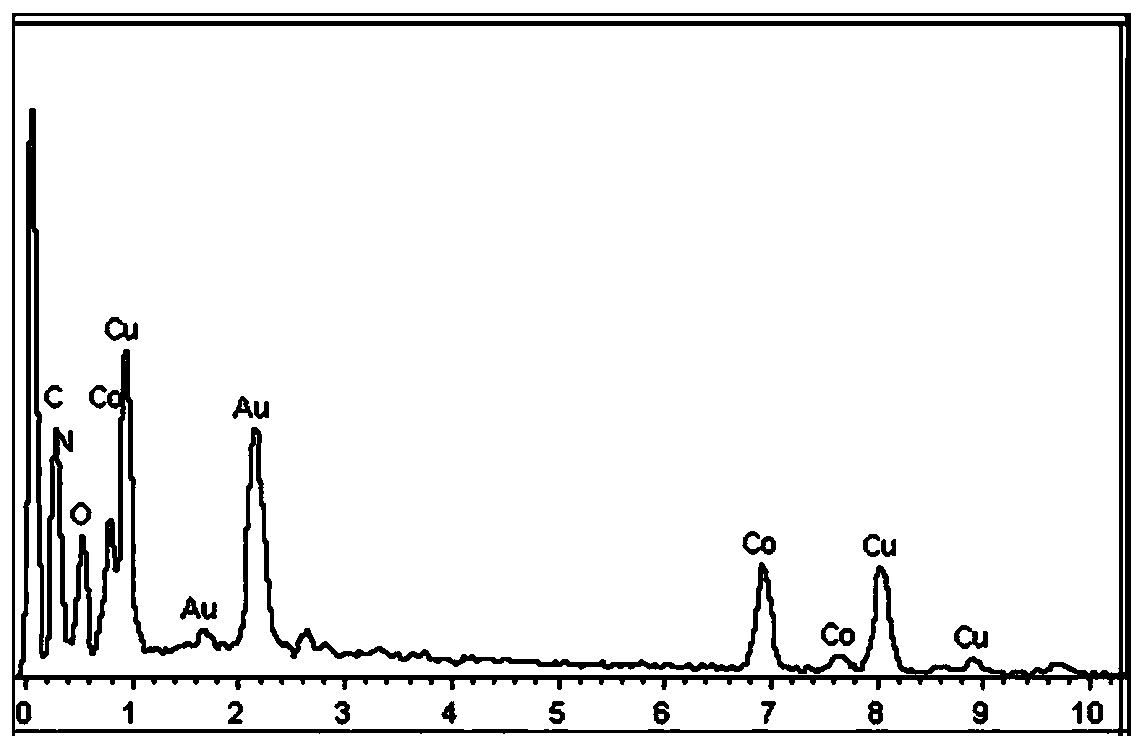

[0043] Add 1.0 g of polyacrylonitrile-b-polystyrene block copolymer (PAN-b-PS), 0.1 g of cobalt acetate, and 0.3 g of copper acetate into a mixed solution of 10 mL of dimethylformamide and chloroform (3 : 1), heated and stirred in a water bath at 50° C. for 10 h to obtain a fully dispersed spinning precursor solution.

[0044] Under the conditions of spinning voltage of 15KV, spinning distance of 15cm, and injection rate of 0.5mL / h, the spinning solution of polyacrylonitrile-b-polystyrene block copolymer (PAN-b-PS) was used as raw material for electrostatic Spinning to obtain the precursor PAN-b-PS nanofibers.

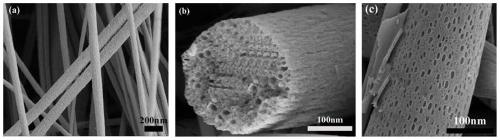

[0045] (2) Preoxidation and carbonization of the precursor PAN-b-PS nanofibers

[0046] The precursor PAN-b-PS nanofibers were placed in a tube furnace, raised to 200°C at a rate of 2°C / min, kept for 2h, then raised to 800°C at a rate of 5°C / min, kept for 2h, and then cooled To room temperature, the transition metal oxide ...

Embodiment 2

[0054] (1) Preparation of precursor fiber

[0055] Add 0.9 g of polystyrene-b-poly-2-vinylpyridine block copolymer (PS-b-PVP), 0.4 g of cobalt nitrate, and 0.1 g of nickel nitrate into a mixed solution of 10 mL of ethanol and chloroform (1: 3), stirring at room temperature for 24 hours to obtain a fully dispersed spinning precursor solution.

[0056] Under the conditions of spinning voltage of 17KV, spinning distance of 15cm, and injection rate of 1mL / h, polystyrene-b-poly2-vinylpyridine block copolymer (PS-b-PVP) spinning solution was used as raw material Electrospinning was carried out to obtain precursor PS-b-PVP nanofibers.

[0057] (2) Preoxidation and carbonization of the precursor PS-b-PVP nanofibers

[0058] Place PS-b-PVP nanofibers in a tube furnace, raise it to 200°C at a rate of 3°C / min, keep it for 1.5h, then raise it to 600°C at a rate of 3°C / min, keep it for 3h, and then cool to At room temperature, a PS-b-PVP-based carbon fiber (NiCo 2 o 4 -PS-b-PVP CNFs)....

Embodiment 3

[0066] (1) Preparation of precursor fibers

[0067] Add 1.5 g of polyvinylpyrrolidone-b-polymethyl methacrylate block copolymer (PVP-b-PMMA), 0.5 g of ferric nitrate, and 0.2 g of zinc acetate into a mixed solution of 10 mL of ethanol and dichloromethane (1 : 1), heated and stirred at 50°C for 24h to obtain a fully dispersed spinning precursor solution.

[0068] Under the conditions of spinning voltage 16KV, spinning distance 18cm, and injection rate of 1.5mL / h, polyvinylpyrrolidone-b-polymethylmethacrylate block copolymer (PVP-b-PMMA) spinning solution Electrospinning is carried out as a raw material to obtain a precursor PVP-b-PMMA nanofiber.

[0069] (2) Preoxidation and carbonization of the precursor PVP-b-PMMA nanofibers

[0070] PVP-b-PMMA nanofibers were placed in a tube furnace, raised to 300°C at a rate of 5°C / min, kept for 3h, then raised to 900°C at a rate of 5°C / min, kept for 2h, and then cooled to room temperature , to obtain PVP-b-PMMA-based carbon fibers load...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com