Bacillus subtilis natto for high yield rate of vitamin K2 (MK-7) and application thereof

A technology of Bacillus natto and MK-7, applied in the field of microorganisms, can solve the problems of long fermentation period and high time cost, and achieve the effects of stable yield, saving time and cost, and good genetic stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Isolation and identification of initial bacterial strain Bacillus subtilis natto (Bacillus subtilis natto) ND-1 and preservation of bacterial strain

[0027] (1) Isolation and screening of Bacillus subtilis natto ND-1

[0028] The present invention buys natto from the market, weighs 1.0-2.0g soil sample in a 250mL triangular flask, suspends it with 10-50mL physiological saline, then carries out gradient dilution, and takes 0.1mL dilution and spreads it on a nutrient agar plate for cultivation . After culturing at 37°C for 8 hours, a single colony with better growth was selected for fermentation verification. Pick a single colony and inoculate it into a fresh liquid seed medium, cultivate it at 37°C and 90-120r / min for 8h, and then insert a 2% (w / w) inoculum into a fermentation medium with a liquid volume of 30mL / 250mL, After fermenting for 3-6 days at 37°C under static culture conditions, the fermented liquid is collected, extracted with an extractant and t...

Embodiment 2

[0034] Example 2: Utilizing ARTP to ND-1 mutagenesis and utilizing structural analogues to carry out preliminary screening of mutagenized strains

[0035] (1) Preparation of bacterial suspension

[0036] Pick a ring of Bacillus subtilis natto ND-1 strain on the nutrient agar medium, inoculate it in a 250mL Erlenmeyer flask containing 30mL seed medium, place it on a shaker at 120r at 37°C Cultivate at a rotational speed of 1 / min for 8 hours to the logarithmic phase, and centrifuge to suspend the bacteria with physiological saline. Properly dilute the bacteria with normal saline to an OD value between 0.8-1.2, put the metal slide on the outer flame of the alcohol lamp in the ultra-clean bench, burn it, put it on a sterilized glass plate after cooling, and take the bacteria suspension The solution was evenly applied to the slide, and the mutagenesis was carried out without air drying.

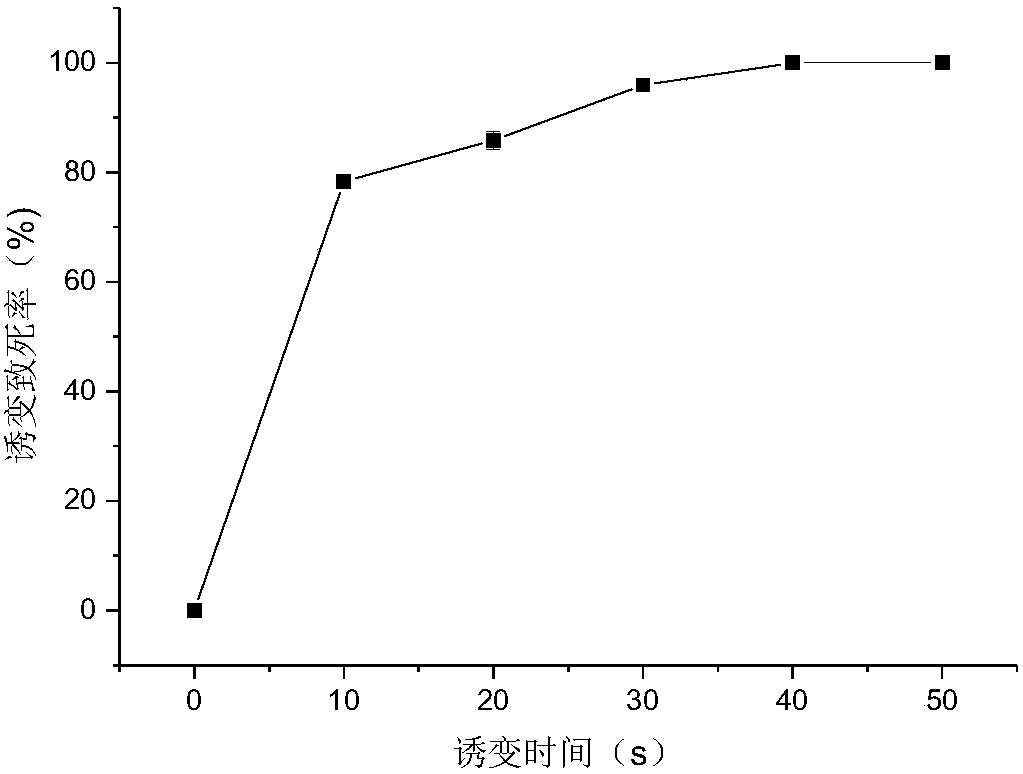

[0037] (2) ARTP mutagenesis

[0038] The operating compartment of the mutagenesis system is...

Embodiment 3

[0041] Example 3: Fermentative production of vitamin K2 (MK-7) by strains after preliminary screening by mutagenesis

[0042] (1) Preparation of cell liquid culture of mutagenized strains

[0043] Pick 31 mutagenic strains and the initial strain Bacillus subtilis natto (Bacillus subtilis natto) ND-1 on the medium containing structural analog resistance respectively and inoculate them in a 250mL Erlenmeyer flask containing 30mL seed medium. Cultivate on a shaker at 120 r / min for 8 hours to the logarithmic phase at a temperature of 100° C. to obtain a liquid cell culture of the mutagenized strain.

[0044] (2) The composition and proportioning of the fermentation medium are:

[0045] Glycerin 50g / L; yeast powder 50g / L; soybean peptone 189g / L; dipotassium hydrogen phosphate 0.6g / L;

[0046] (3) Shake flask fermentation:

[0047] Inoculate the liquid cell culture of the above bacterial strain in a 250mL Erlenmeyer flask with 30mL of sterilized fermentation medium at an inoculum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com