Bacillus subtilis engineering bacteria for efficiently expressing plasmin and preparation method thereof

A high-efficiency expression technology of Bacillus subtilis, which is applied in the field of high-efficiency expression of Bacillus subtilis engineering bacteria and preparation of plasmin, can solve the problems of plasmin production and enzyme activity defects, etc., and achieve the effect of clear route and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

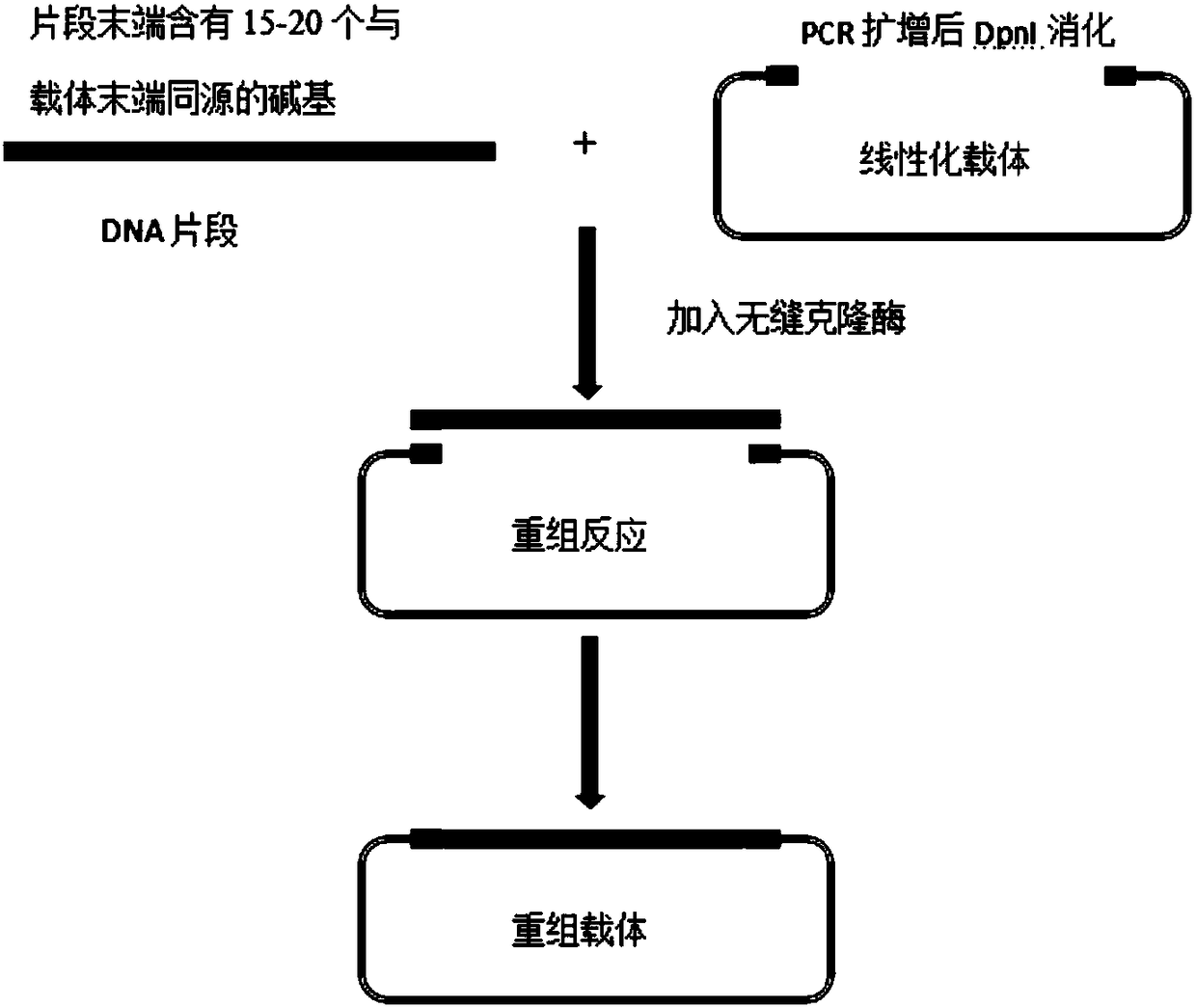

[0040] Construction of 9 Knockout Vectors

[0041] The Bacillus subtilis strain (B. subtilis) comes from the China Industrial Microorganism Culture Collection Center (CICC), and the preservation number is No. 20637.

[0042](1) Genomic DNA extraction of Bacillus subtilis: pick a single colony of B. subtilis in 5ml LB liquid medium, culture overnight at 37°C with shaking, collect the bacteria by centrifugation at 12000r / min for 5min; wash the bacteria once with STE; add 200μl Solution I solution and 20μl 100mg / ml lysozyme, resuspended bacteria, placed at 37°C for 2-3h or placed in a refrigerator at 4°C overnight; add 200μl 10% SDS, 50-60°C water bath for 30min until clarified; add 100μl or 200μl 5mol / L NaCl, mix well and centrifuge at 12000r / min for 5min, take the supernatant into a clean centrifuge tube; extract twice with equal volume of phenol / chloroform, take the supernatant into a clean centrifuge tube; add 2 times the volume of absolute ethanol Precipitate at -20°C for 2...

Embodiment 2

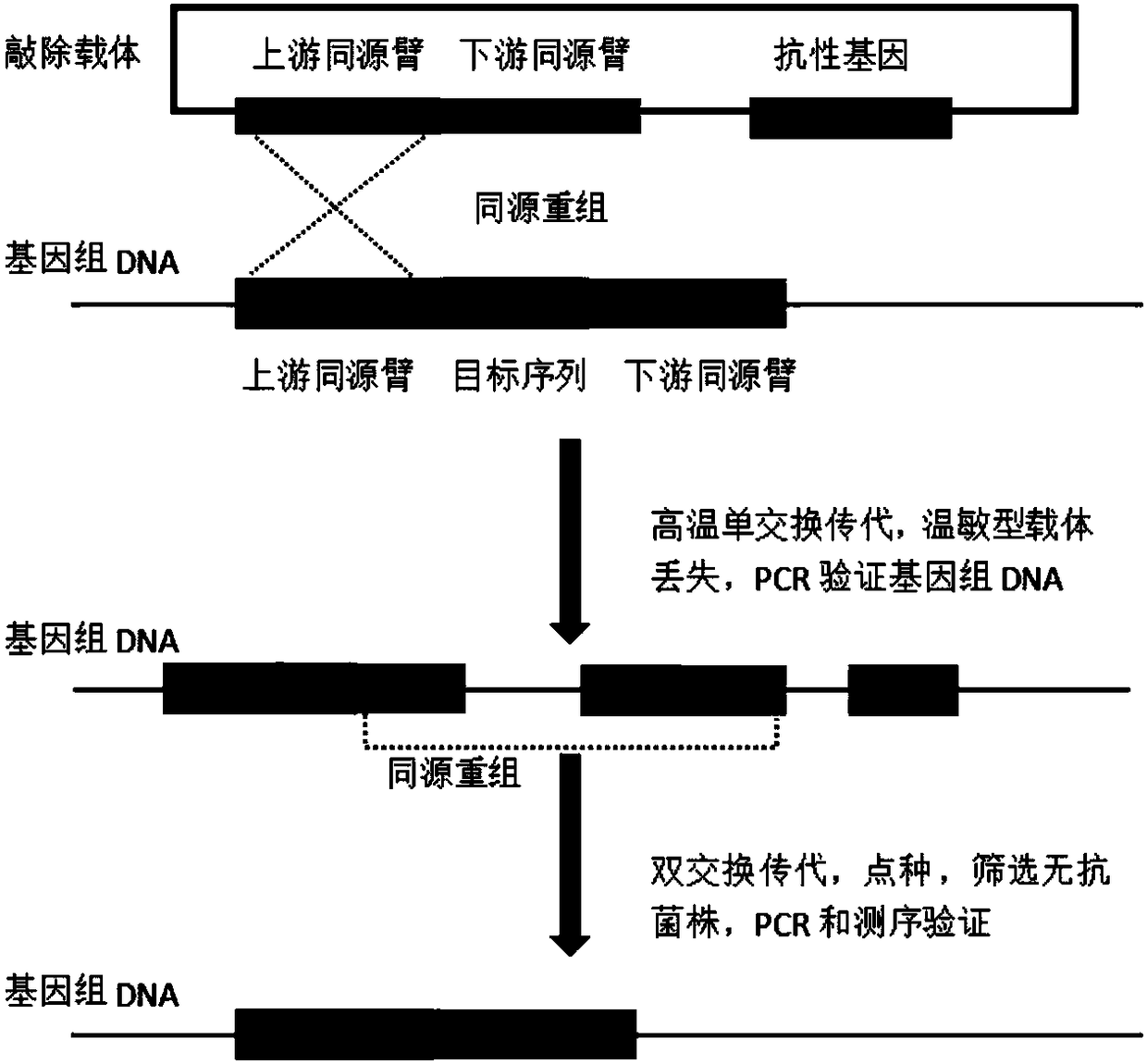

[0057] Gene knockout in Bacillus subtilis

[0058] (1) Competent preparation of Bacillus subtilis: pick a single colony of B.subtilis in 5ml LB medium, and culture overnight at 37°C with shaking; the seed solution is transferred to 50ml B.subtilis electroporation growth medium with 5% inoculum , 37 ° C, 250r / min shaking culture 2-3h to OD 600 If the temperature is 0.85-0.95, put the bacterial solution in ice bath for 10 minutes; centrifuge at 5000r / min for 5 minutes to collect the bacterial cells, wash the bacterial cells with B. subtilis electroporation washing medium for 4 times, and finally resuspend the cells with 1ml of washing medium, and aliquot to 1.5ml In centrifuge tubes, 100 μl per tube was stored at -80°C, namely competent cells, and the above steps were performed on ice.

[0059] (2) Electroporation: Take a tube of competent cells and add 5-10 μl plasmid DNA (single knockout vector), mix gently and transfer to a pre-cooled electroporation cup (0.2 cm), ice bath f...

Embodiment 3

[0065] Fermentation of engineering strains and detection of plasmin activity

[0066] (1) Strain activation: Pick the B.subtilis 20637 and B.subtilis 20637Δ9 strains preserved in glycerol tubes and streak them on the LB plate, culture at 37°C for 12 hours, pick a single colony and streak it on the LB plate, and culture at 37°C 12h;

[0067] (2) Seed culture: Pick a single colony from the LB solid medium and inoculate it into 50 ml of liquid seed medium at a rotation speed of 220 r / min, shake and culture at 37°C for 12 hours, and use it as a fermented seed liquid;

[0068] (3) Fermentation culture: a 3L fermenter was used, the liquid volume was 1.5L, the inoculum size was 2%, and the fermentation temperature was set at 37°C. The stirring speed is 800r / min, the ventilation rate is 2L / min, the pH is controlled at 6.8-7.2, and the fermentation is 48h.

[0069] (4) Detection of plasmin enzyme activity: refer to patent CN103937830B, the specific operation is as follows: ① draw 1ml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com