Production method of multifunctional textile finishing agent

A fabric finishing agent and multi-functional technology, which is applied in fiber treatment, textiles and papermaking, and flame-retardant fibers, etc. Obvious burning effect, good durability, good washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of multifunctional fabric finishing agent, described preparation method comprises: (1) the preparation of nanometer DNA / Ag: at first DNA, silver nitrate (AgNO 3 ), ascorbic acid was dissolved in deionized water, and prepared respectively into a DNA solution with a mass concentration of 3g / L, and an AgNO solution with a molar concentration of 0.03M 3 solution and ascorbic acid solution; DNA solution was then mixed with AgNO 3 Mix the solutions, let stand at room temperature for 20 hours, then heat to 40°C, add ascorbic acid solution drop by drop under magnetic stirring conditions (the volume ratio of the three is 1:1:1), adjust the pH value to 5 with sodium hydroxide solution, and keep warm for reaction After 1 hour, centrifuge at 10,000 rpm, wash repeatedly for 3 times, and then vacuum-dry at 50°C to obtain nano-DNA / Ag powder;

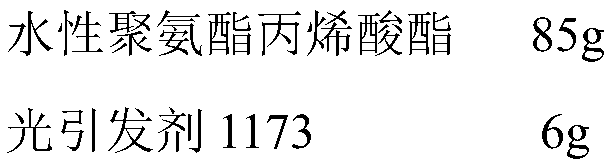

[0028] (2) Preparation of multifunctional finishing agent: the nano-DNA / Ag powder obtained by water-based photocu...

Embodiment 2

[0033] A kind of preparation method of multifunctional fabric finishing agent, described preparation method comprises: (1) the preparation of nanometer DNA / Ag: at first DNA, silver nitrate (AgNO 3 ), citric acid were dissolved in deionized water, respectively prepared into a DNA solution with a mass concentration of 5g / L, and an AgNO solution with a molar concentration of 0.05M 3 solution and citric acid solution; then the DNA solution was mixed with AgNO 3 Mix the solutions, let stand at room temperature for 12 hours, then heat to 50°C, add citric acid solution dropwise under magnetic stirring conditions (the volume ratio of the three is 1:1:1), adjust the pH value to 4 with sodium hydroxide solution, and keep warm After reacting for 2 hours, centrifuge at 10,000 rpm, wash repeatedly for 3 times, and vacuum-dry at 50° C. to obtain nano-DNA / Ag powder.

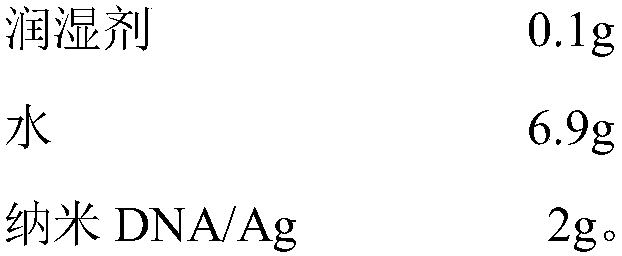

[0034] (2) Preparation of multifunctional finishing agent: the nano-DNA / Ag powder obtained by water-based photocurable resin...

Embodiment 3

[0038] A kind of preparation method of multifunctional fabric finishing agent, described preparation method comprises: (1) the preparation of nanometer DNA / Ag: at first DNA, silver nitrate (AgNO 3), tannic acid was dissolved in deionized water, respectively prepared into a DNA solution with a mass concentration of 1g / L, and an AgNO solution with a molar concentration of 0.01M 3 solution and tannic acid solution; then the DNA solution was mixed with AgNO 3 Mix the solutions, let stand at room temperature for 24 hours, then heat to 50°C, add tannic acid solution dropwise under magnetic stirring conditions (the volume ratio of the three is 1:1:1), adjust the pH value at 7 with sodium hydroxide solution, After incubation for 1.5 hours, centrifuge at 10,000 rpm, wash repeatedly for 3 times, and vacuum-dry at 50°C to obtain nano-DNA / Ag powder.

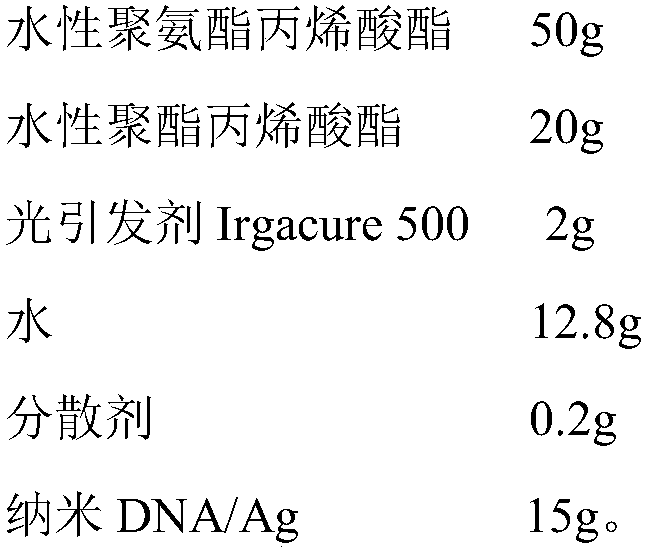

[0039] (2) Preparation of multifunctional finishing agent: the nano-DNA / Ag powder obtained by water-based photocurable resin, photoinitiat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com