High-density optical waveguide structure, printing circuit board and preparation method thereof

A technology for printed circuit boards and optical waveguides, which is applied in the fields of printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve the problems of poor bonding force, easy falling off or peeling of optical waveguide lines, etc., to increase bonding force, Effect of low loss and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

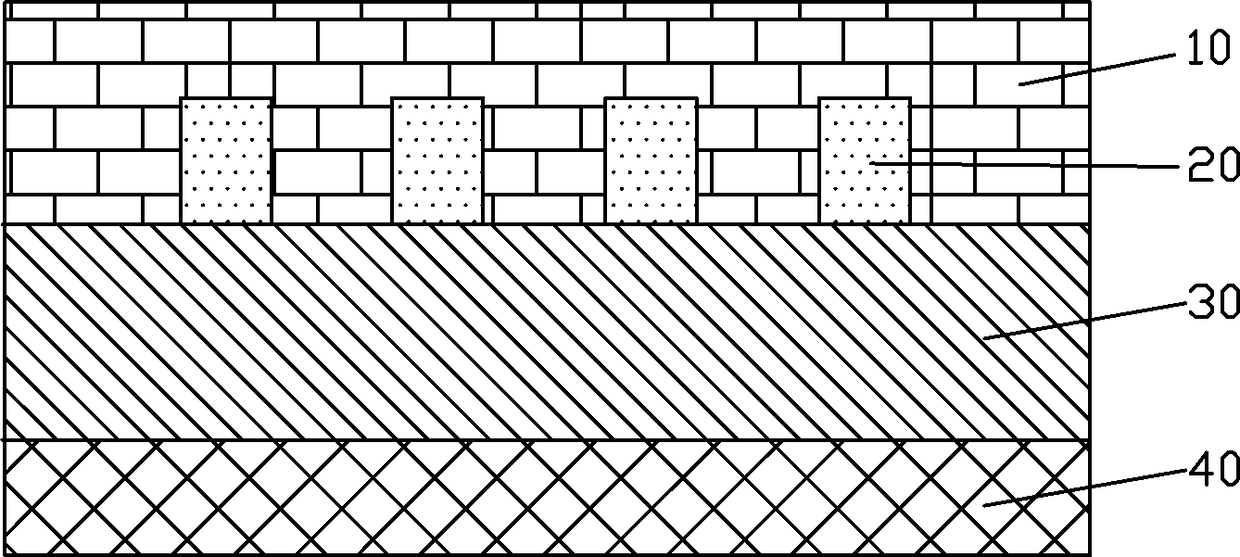

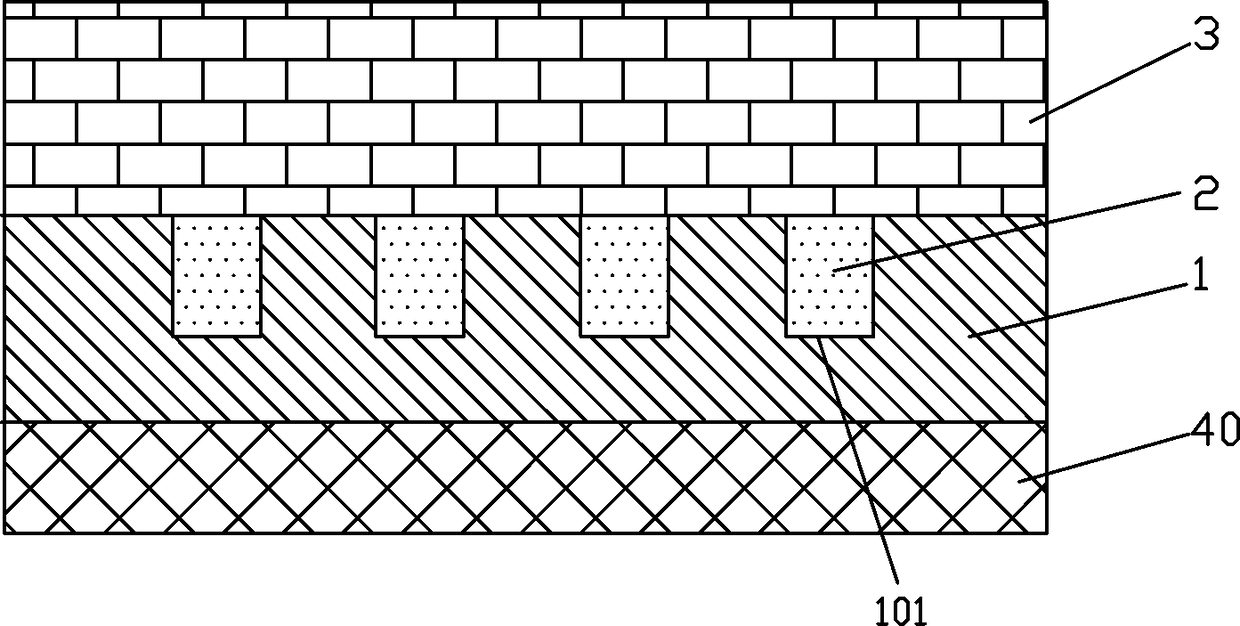

[0059] see figure 2 , the high-density optical waveguide structure of the present invention, which includes a lower cladding layer 1, a core layer 2, and an upper cladding layer 3; wherein, a plurality of grooves 101 are arranged at intervals in the lower cladding layer 1, and the grooves 101 are filled with light The waveguide material forms the core layer 2.

[0060] In this embodiment, the trench 101 is rectangular.

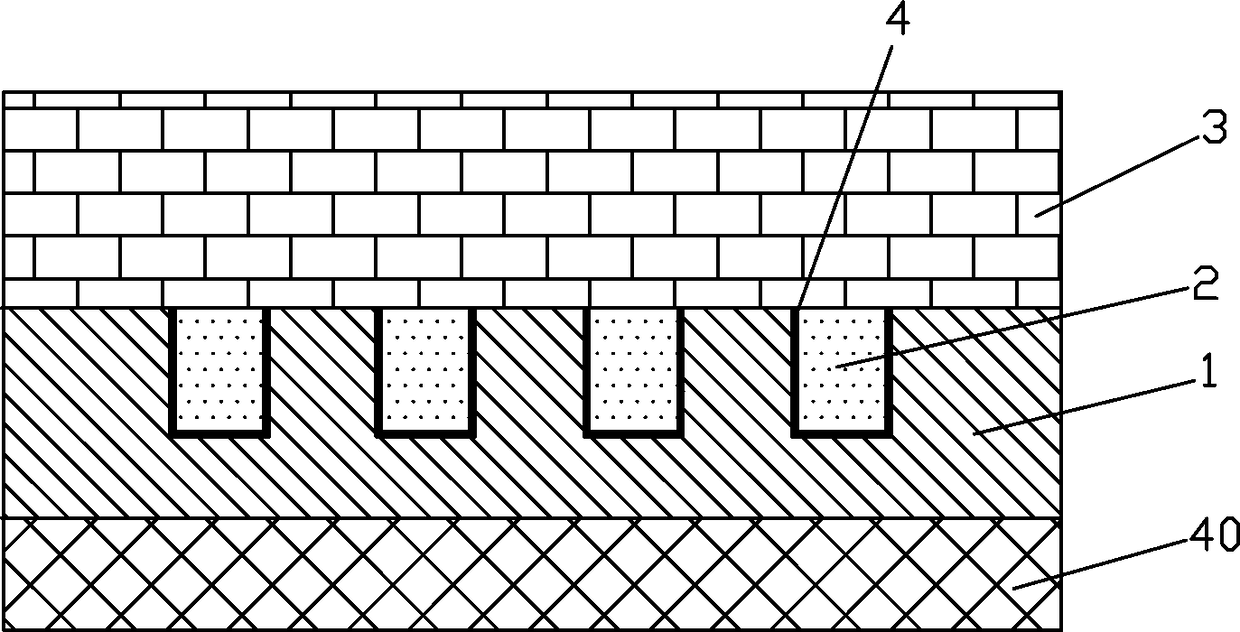

[0061] see image 3 , the inner wall of the groove 101 in the lower cladding layer 1 is provided with a reflective film 4, the thickness of the reflective film 4 is 0.1 nm-50 μm; the material of the reflective film 4 is polysiloxane.

[0062] see Figure 4 ~ Figure 7 , the longitudinal cross-sectional shape of the trench 101 in the lower cladding layer 1 is trapezoidal, circular, elliptical, or triangular.

[0063] Preferably, the optical waveguide material is acrylate, polymethyl methacrylate and its derivative fluoride, epoxy resin, fluorine-containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com