Mulberry leaf composite protein source replacing fish meal and preparation method of protein source

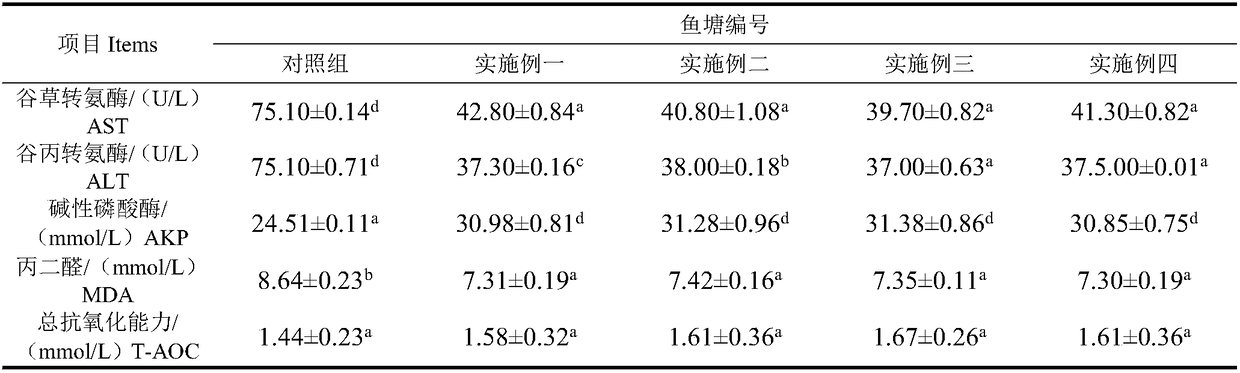

A compound protein and fish meal replacement technology, which can be applied in the direction of climate change adaptation, animal feed, additional food elements, etc., can solve the problems of increasing production costs and burdens, and achieve the goals of promoting growth, reducing malondialdehyde content, and improving lipid metabolism Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

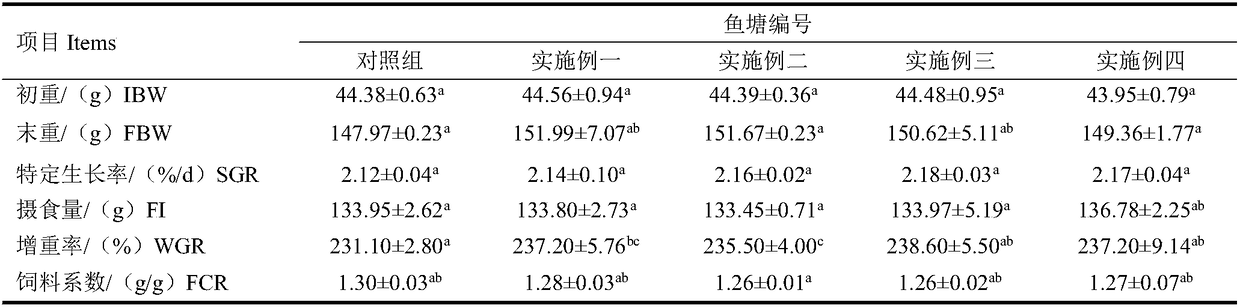

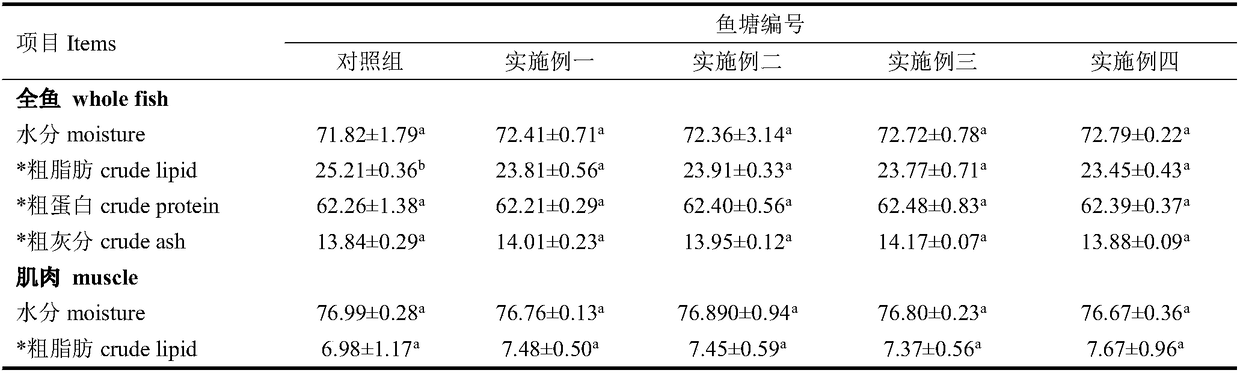

Examples

Embodiment 1

[0032] The mulberry leaves, soybean meal, cottonseed meal and DL-methionine are produced according to the weight percentage of 14%: 43%: 42.7%: 0.3%,

[0033] Step 1: making mulberry leaf powder; drying mulberry leaves to semi-dry, chopped, drying at 75°C for 3 hours, and then crushed to 60 mesh;

[0034] Step 2: making soybean meal powder and cotton meal powder; drying soybean meal and cotton meal at 75°C for 3 hours, and then pulverizing to 60 mesh;

[0035] Step 3: mixing; mixing mulberry leaf powder, soybean meal powder and cottonseed meal powder, mixing and stirring for 5min;

[0036] Step 4: add DL-methionine, continue to mix and stir for 5 minutes, and obtain the mulberry leaf compound protein source.

[0037] The moisture content, crude protein content and crude fat content in the obtained mulberry leaf composite protein source were detected, and the obtained detection data were shown in Table 1.

Embodiment 2

[0039] The mulberry leaves, soybean meal, cottonseed meal and DL-methionine are produced according to the weight percentage of 16%: 42%: 41.7%: 0.3%,

[0040] Step 1: making mulberry leaf powder; drying mulberry leaves to semi-dry, chopped, drying at 75°C for 4 hours, and then crushed to 70 mesh;

[0041] Step 2: making soybean meal powder and cotton meal powder; drying soybean meal and cotton meal at 75°C for 4 hours, and then pulverizing to 70 mesh;

[0042] Step 3: mixing; mixing mulberry leaf powder, soybean meal powder and cottonseed meal powder, mixing and stirring for 10min;

[0043] Step 4: add DL-methionine, and continue to mix and stir for 8 minutes to obtain a mulberry leaf compound protein source.

[0044] The moisture content, crude protein content and crude fat content in the obtained mulberry leaf composite protein source were detected, and the obtained detection data were shown in Table 1.

Embodiment 3

[0046] The mulberry leaves, soybean meal, cottonseed meal and DL-methionine are produced according to the weight percentage of 18%: 41.6%: 39%: 0.4%,

[0047] Step 1: making mulberry leaf powder; drying mulberry leaves to semi-dry, chopped, drying at 75°C for 3.5 hours, and then crushed to 70 mesh;

[0048] Step 2: making soybean meal powder and cotton meal powder; drying soybean meal and cotton meal at 75°C for 3.5 hours, and then pulverizing to 70 mesh;

[0049] Step 3: mixing; mix mulberry leaf powder, soybean meal powder and cottonseed meal powder, mix and stir for 8min;

[0050] Step 4: add DL-methionine, and continue to mix and stir for 8 minutes to obtain a mulberry leaf compound protein source.

[0051] The moisture content, crude protein content and crude fat content in the obtained mulberry leaf composite protein source were detected, and the obtained detection data were shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com