Desulfurization, denitration and dust removal system and desulfurization, denitration and dust removal process

A desulfurization, denitrification, and dust removal system technology, applied in the desulfurization, denitrification, and dust removal systems, desulfurization, denitrification, and dust removal process fields, can solve the problems of single structure, low purification efficiency, etc., and achieve the effects of improving efficiency, facilitating manufacturing and processing, and reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

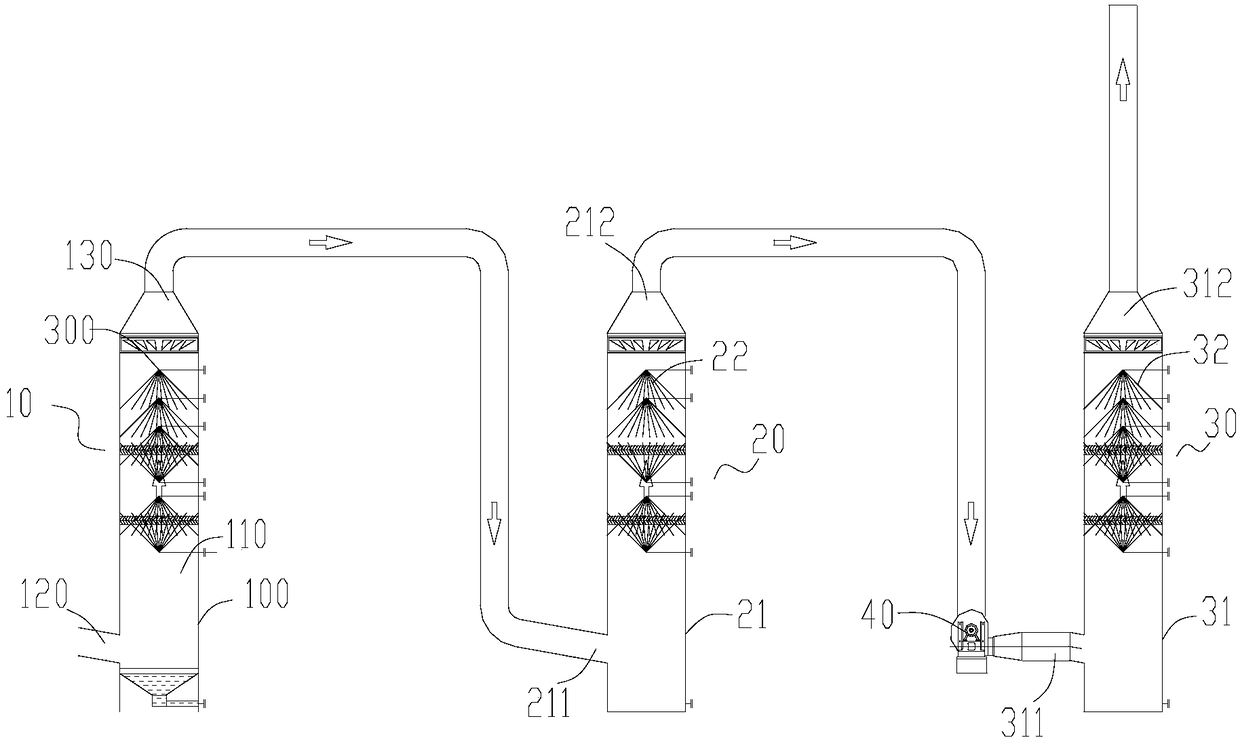

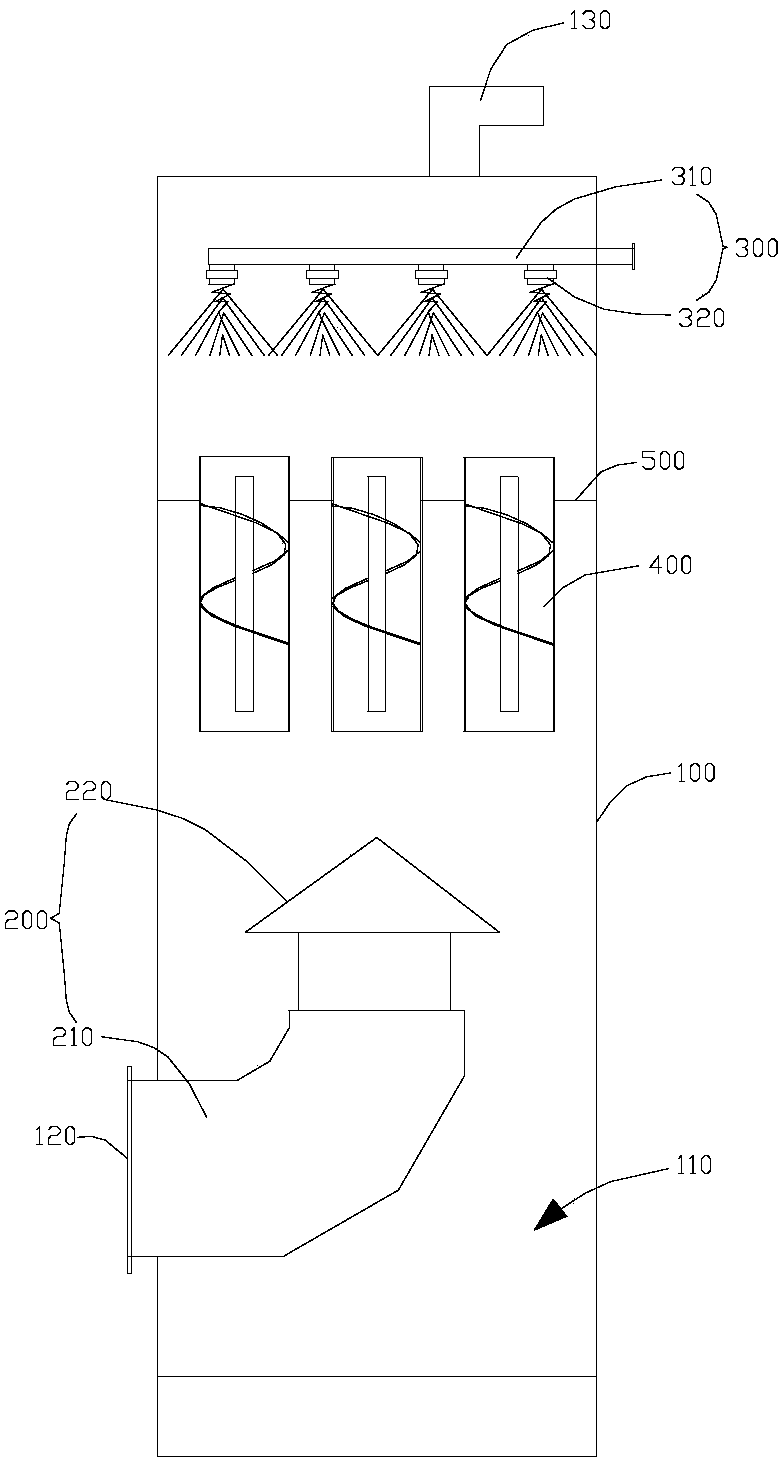

[0041] see figure 1 - Figure 4 , this embodiment provides a desulfurization, denitrification and dust removal system, which includes a first purification unit 10 , a second purification unit 20 and an integrated purification unit 30 . During the purification process, the flue gas passes into the first purification unit 10, the second purification unit 20 and the comprehensive purification unit 30 in sequence, the nitric oxide in the flue gas undergoes an oxidation reaction to generate nitrogen dioxide, and the nitrogen dioxide undergoes a reduction reaction to generate nitrogen gas , sodium hydroxide and water, reduce secondary pollution and improve efficiency.

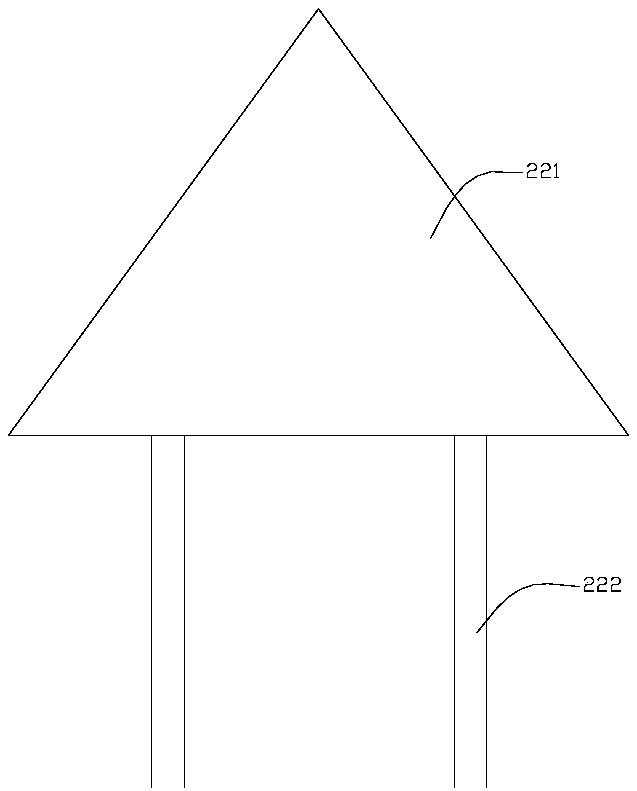

[0042] The first purification unit 10 includes a washing and oxidation tower 100 , a first spray assembly 300 , a flue gas mixing assembly 200 and a confluence assembly 400 .

[0043] Optionally in this embodiment, the washing and oxidation tower 100 includes a first gas inlet 120, a first gas outlet 130, and a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com