CdIn2S4 nanodot hybrid TiO2 hollow sphere composite photocatalyst, preparation method and application thereof

A cdin2s4, hollow sphere technology, used in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of limited wide application, high photo-generated electron-hole pair recombination efficiency, and improve separation efficiency. , Excellent light harvesting ability, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

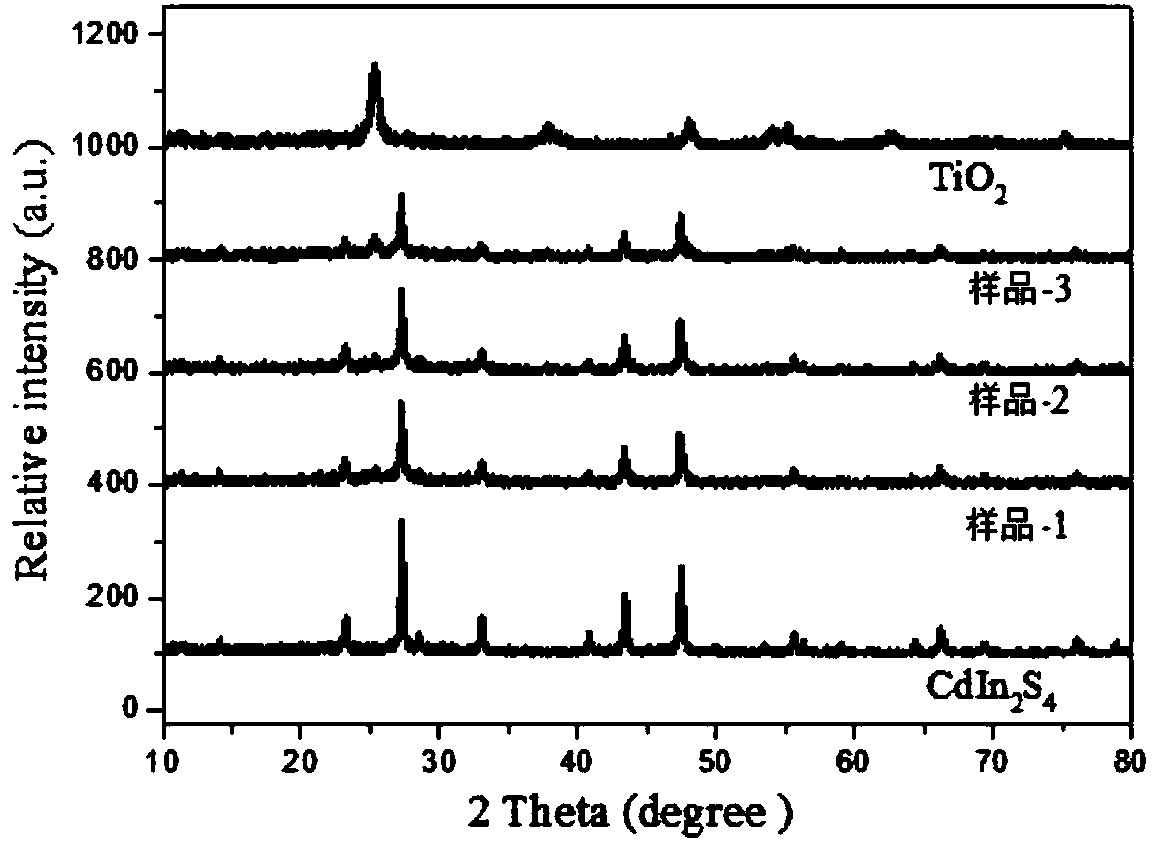

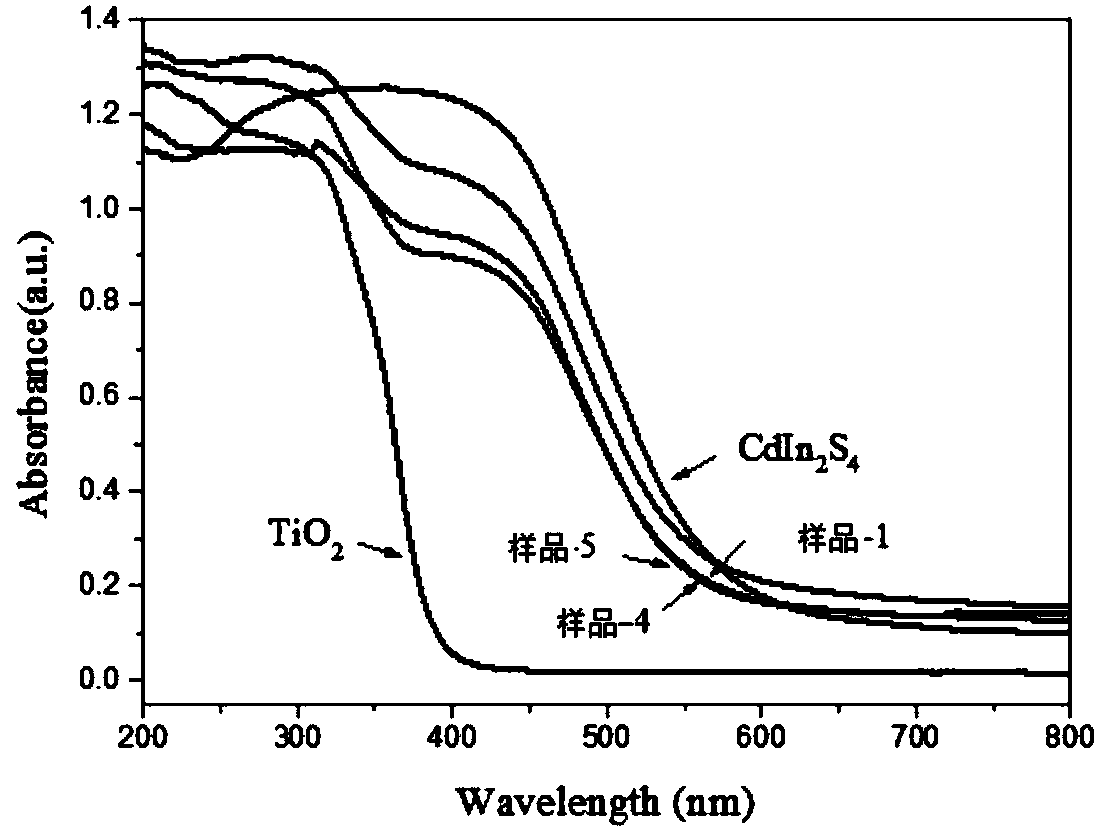

example 1

[0024] (1) Weigh cadmium nitrate tetrahydrate, indium nitrate hydrate and L-cysteine amine sequentially according to the molar ratio of 0.2:0.4:1.6 and add them to 10ml of deionized water, and stir until a transparent mixed solution;

[0025] (2) Weigh 0.01g of TiO 2 Add the hollow spheres to 10ml of absolute ethanol, and stir ultrasonically for a period of time to form a uniformly dispersed TiO 2 Hollow sphere suspension;

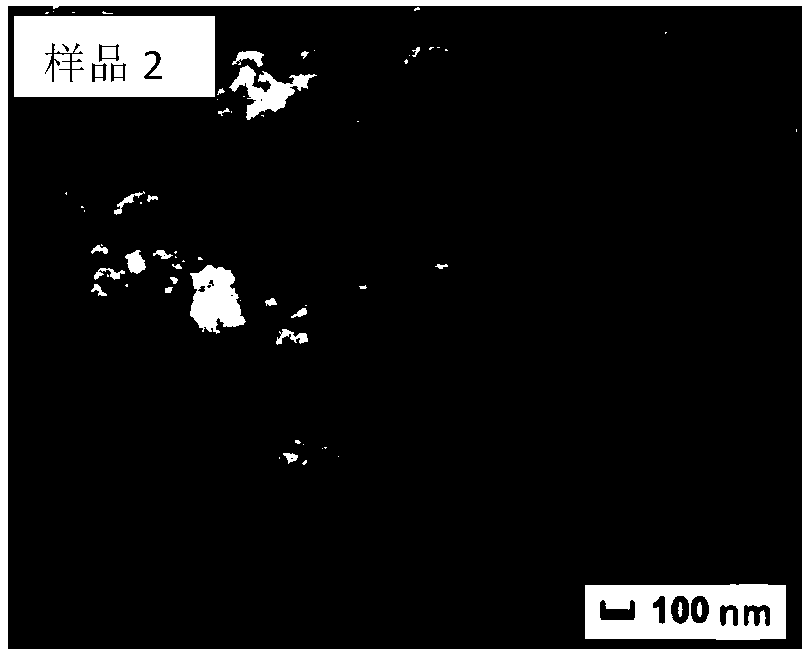

[0026] (3) TiO obtained in step (2) 2The hollow sphere suspension was added dropwise to the transparent solution prepared in step (1), the process was carried out under stirring, then continued to stir for 10 minutes, and then ultrasonically dispersed for 10 minutes, and then moved the uniformly dispersed mixed solution into the polytetrafluoroethylene-lined In a high-pressure reactor, react at 160°C for 18 hours. After the reaction is completed, cool to room temperature naturally, centrifuge the solid in the solution, wash it with ethanol and water th...

example 2

[0031] (1) Weigh cadmium nitrate tetrahydrate, indium nitrate hydrate and L-cysteine amine sequentially according to the molar ratio of 0.4:0.8:3.2 and add them to 15ml of deionized water, and stir until a transparent mixed solution;

[0032] (2) Weigh 0.53g of TiO 2 Add the hollow spheres to 15ml of absolute ethanol, and stir ultrasonically for a period of time to form a uniformly dispersed TiO 2 Hollow sphere suspension;

[0033] (3) TiO obtained in step (2) 2 The hollow sphere suspension was added dropwise to the transparent solution prepared in step (1), the process was carried out under stirring, then continued to stir for 20 minutes, and then ultrasonically dispersed for 20 minutes, and then moved the uniformly dispersed mixed solution into the Teflon-lined In a high-pressure reactor, react at 180°C for 24 hours. After the reaction is completed, cool to room temperature naturally, centrifuge the solid in the solution, wash it with ethanol and water three times, and d...

example 3

[0038] (1) Weigh cadmium nitrate tetrahydrate, indium nitrate hydrate and L-cysteine ammonium sequentially according to the molar ratio of 0.8:1.6:6.4 and add them to 20ml of deionized water, and stir until a transparent mixed solution;

[0039] (2) Weigh 1.54g of TiO 2 Add the hollow spheres to 20ml of absolute ethanol, and stir ultrasonically for a period of time until uniformly dispersed TiO 2 Hollow sphere suspension;

[0040] (3) TiO obtained in step (2) 2 The hollow sphere suspension was added dropwise to the transparent solution prepared in step (1), the process was carried out under stirring, then continued to stir for 30 minutes, and then ultrasonically dispersed for 30 minutes, and then moved the uniformly dispersed mixed solution into the Teflon-lined In a high-pressure reactor, react at 200 ° C for 28 hours. After the reaction is completed, cool to room temperature naturally, centrifuge the solid in the solution, wash it with ethanol and water three times, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com