Molasses alcohol waste water decolouring method

A technology for molasses alcohol wastewater and process, which is applied in the field of decolorization of molasses alcohol wastewater, can solve the problems of unsatisfactory comprehensive effect, long reaction time, low decolorization rate and the like, and achieves the effects of low cost, short time consumption and high biochemical efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

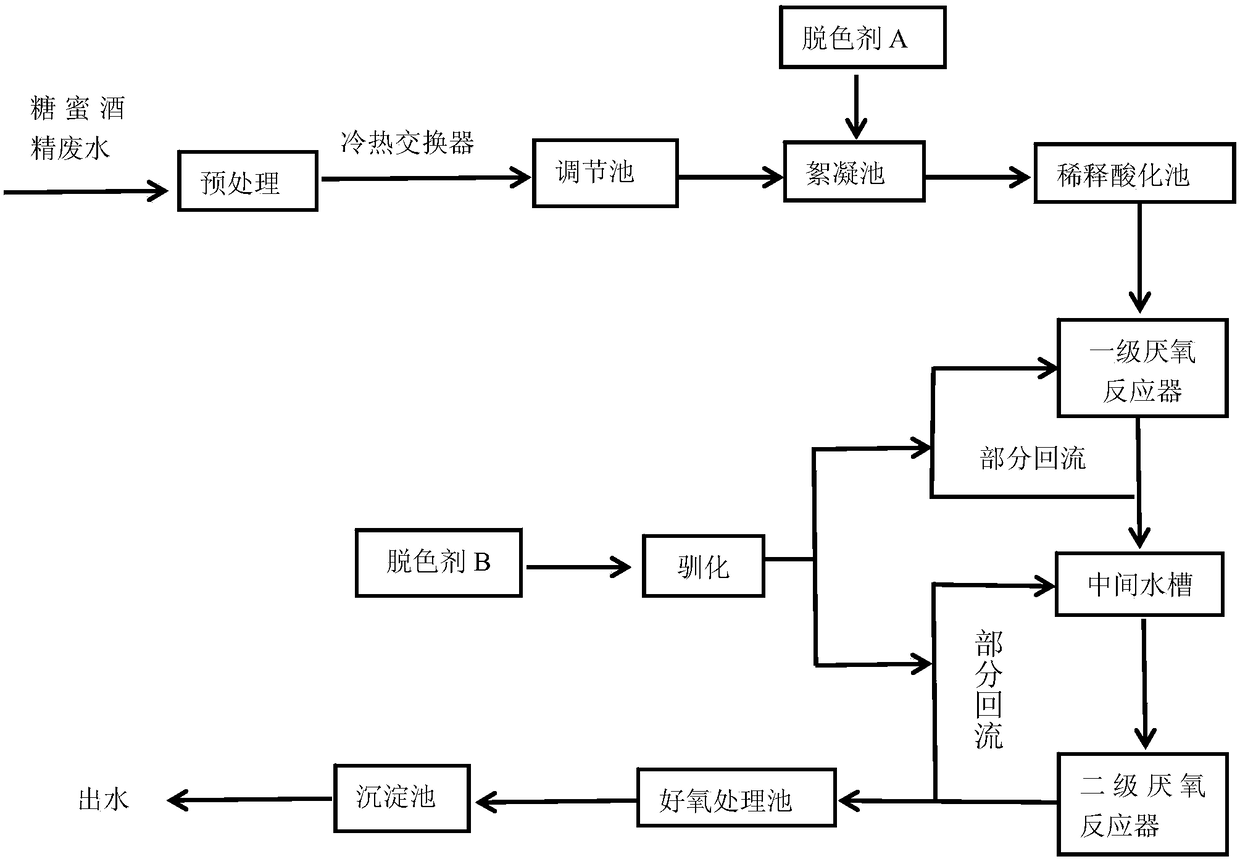

[0020] A kind of molasses alcohol waste water decolorization process, comprises following treatment steps:

[0021] (1) Pretreatment: The CODcr of molasses alcohol wastewater influent is about 12000mg / L, the chroma is about 4000 times, and the design treatment capacity is 1000m 3 / d, the molasses alcohol waste water first passes through the grid to intercept the coarse suspended matter, and then enters the cold heat exchanger for cooling treatment, and is cooled to 42-45°C.

[0022] (2) Entering the regulating pool: the above-mentioned waste water after cooling treatment is passed into the regulating pool, and sodium hydroxide is added to adjust the pH value to 6.8-7.3.

[0023] (3) Entering the flocculation tank: pass the above-mentioned wastewater with adjusted pH value into the sedimentation tank, 3 Add 5-10kg to the waste water and add decolorizer A composed of activated carbon, diatomaceous earth, ethyl hypochlorite, calcium hypochlorite, sodium hypochlorite, polypropyle...

Embodiment 2

[0029] The difference between embodiment 2 and embodiment 1 is only: the CODcr of molasses alcohol wastewater influent is about 15000mg / L, the chroma is about 4500 times, and the design treatment capacity is 1100m 3 / d; the decolorizer A is made up of the following raw materials in parts by weight: 10 parts of activated carbon, 10 parts of diatomaceous earth, 15 parts of ethyl hypochlorite, 10 parts of calcium hypochlorite, 20 parts of sodium hypochlorite, and 7 parts of polyacryl alcohol , 2 parts of chelating agent; Described depigmentation agent B is by volume ratio 1:1 by the bacterium liquid that described decolorizing agent B is made respectively by aspergillus niger, nitrifying bacteria, bacillus subtilis, bacillus licheniformis, sporosporium thermophila, acetic acid bacteria, yeast: 1: 1: 1: 1: 1 mixed, the cell concentration of each bacterial liquid is 1x10 9 cfu / ml.

[0030] After testing, the CODcr of the effluent in this embodiment is 98 mg / L, the chromaticity is ...

Embodiment 3

[0031]The difference between embodiment 3 and embodiment 1 is only: the CODcr of molasses alcohol wastewater influent is about 11000mg / L, the chroma is about 4200 times, and the design treatment capacity is 1300m 3 / d; the decolorizer A is made up of the following raw materials in parts by weight: 5 parts of activated carbon, 5 parts of diatomaceous earth, 10 parts of ethyl hypochlorite, 5 parts of calcium hypochlorite, 8 parts of sodium hypochlorite, and 3 parts of polypropylene alcohol , 0.8 part of chelating agent; The bacterium liquid that described decolorizing agent B is made respectively by Aspergillus niger, nitrifying bacteria, Bacillus subtilis, Bacillus licheniformis, Sporosporium thermophila, acetic acid bacteria, saccharomycete 1.5:1 by volume: 1: 1: 1: 1: 1 mixed, the cell concentration of each bacterial liquid is 1x10 9 cfu / ml.

[0032] After testing, the CODcr of the effluent in this embodiment is 97 mg / L, the chromaticity is 49 times, and the pH value is 7.2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com