High-tetragonal-phase barium titanate powder, method for preparing same, barium titanate thick-film ceramic, method for preparing same and application of barium titanate thick-film ceramic

A technology of phase barium titanate and barium titanate, applied in the field of high tetragonal phase barium titanate powder and its preparation, barium titanate thick film ceramics and its preparation, can solve the problem of large particle size and low activity of barium titanate powder , serious agglomeration of barium titanate powder and other problems, to achieve the effect of high dielectric constant, improved performance and good electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention also provides the preparation method of the high tetragonal phase barium titanate powder of the above technical scheme, comprising the following steps:

[0065] Ba(CH 3 COO) 2 and KOH aqueous solution and Ti(C 4 h 9 O) 4 mixed with the ethanol solution, heated and stirred, and subjected to hydrothermal reaction to obtain high tetragonal phase barium titanate powder.

[0066] In the present invention, the temperature of heating and stirring is 60°C to 80°C;

[0067] The stirring speed of heating and stirring is 100rpm~1000rpm;

[0068] The reaction temperature of the hydrothermal reaction is to first raise the temperature to 80°C-100°C and keep it warm for 10h-20h, then raise the temperature to 160°C-240°C and keep it warm for 60h-100h.

[0069] In the present invention, the molar ratio of Ba ions to Ti ions is 2 to 3:1; the heating and stirring is preferably heating and stirring in a water bath; the hydrothermal reaction is preferably placed ...

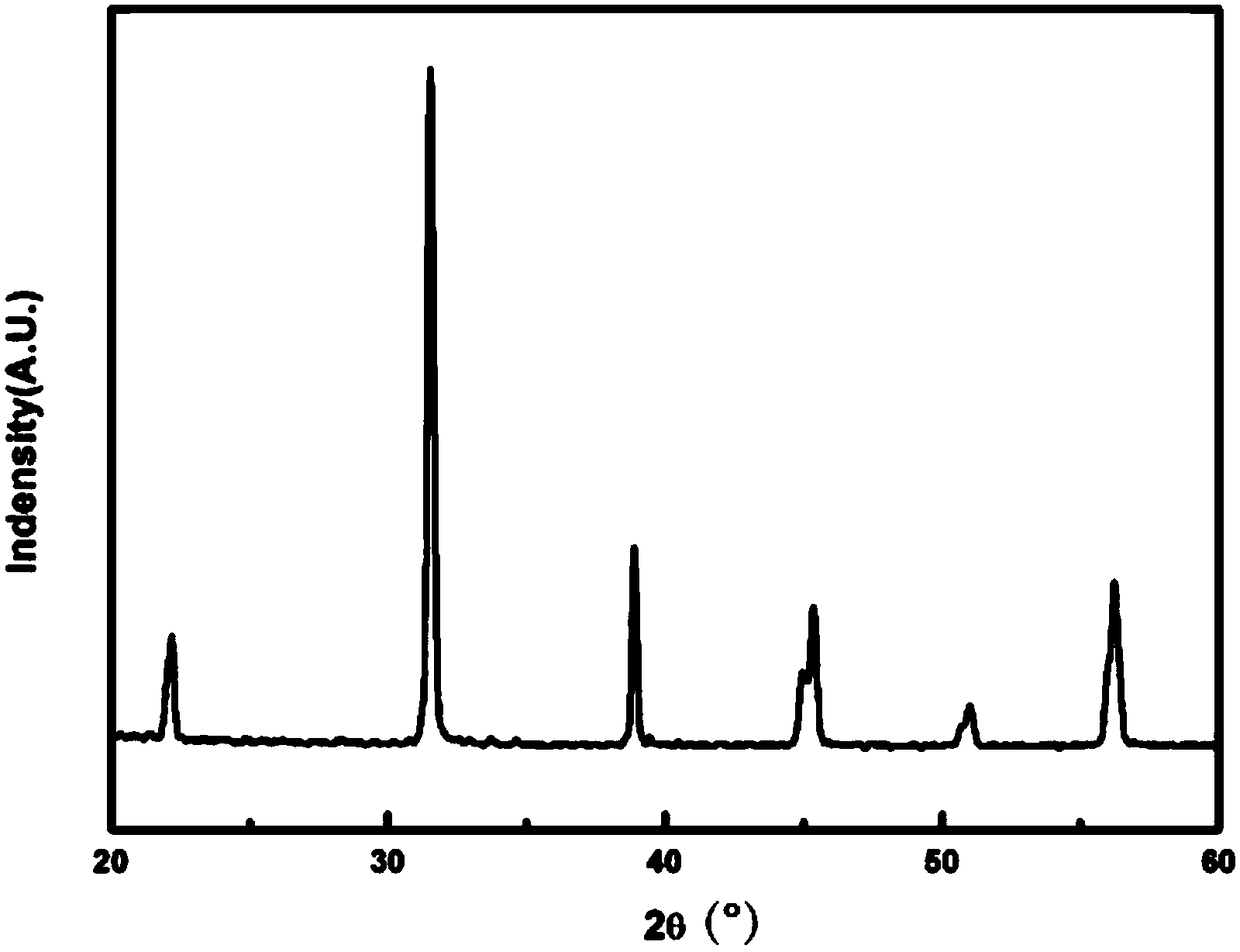

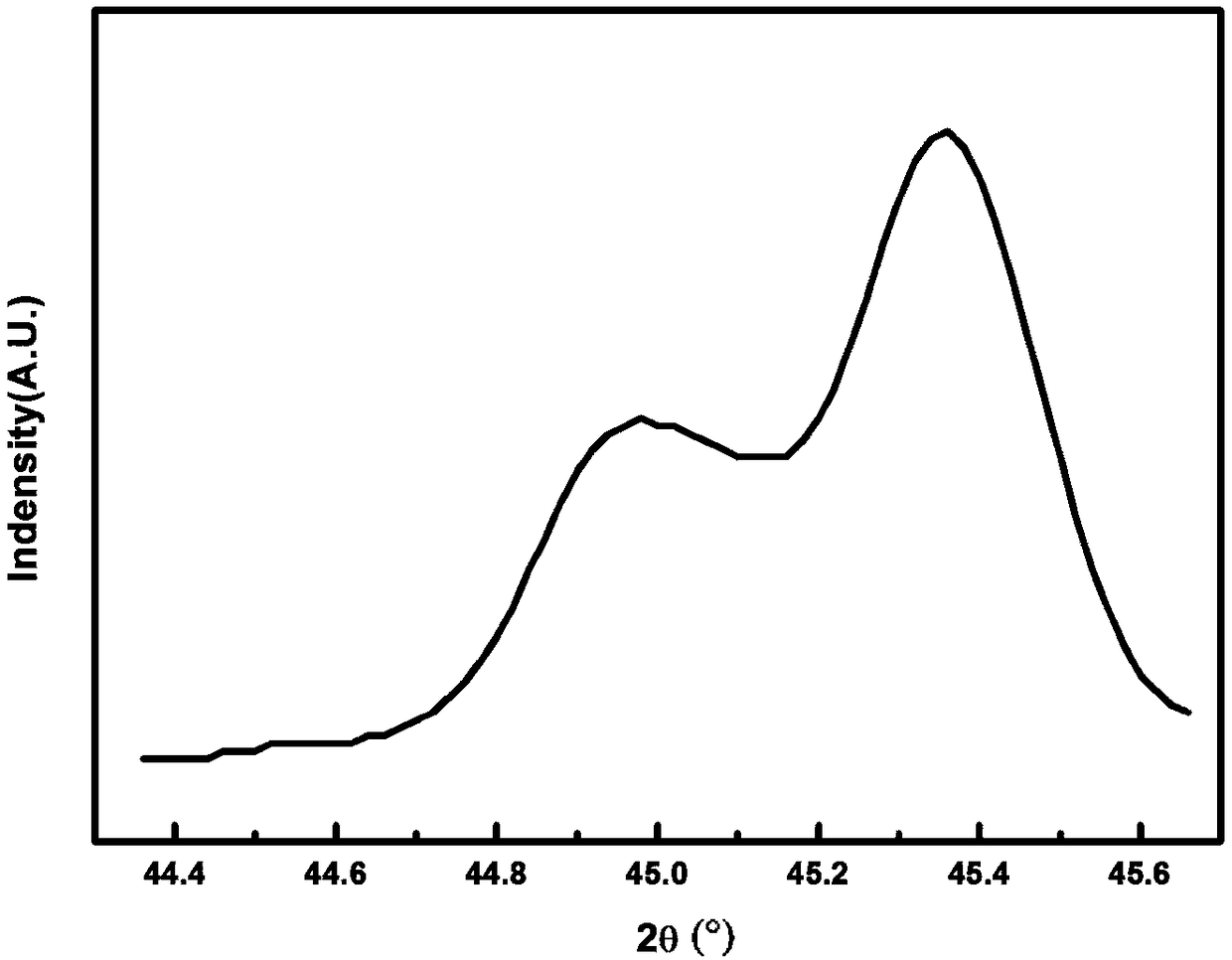

Embodiment 1

[0096] 0.5mol Ba(CH 3 COO) 2 Mix with 2mol KOH and dissolve in 35ml deionized water, the concentration of 0.5mol KOH is 2mol / L, stir magnetically at 75°C for 10min to obtain a barium hydroxide solution. Ti(C 4 h 9 O) 4 Dissolve in absolute ethanol, stir magnetically at 75°C for 15 minutes to obtain Ti(C 4 h 9 O) 4 ethanol solution. Barium hydroxide solution and Ti(C 4 h 9 O) 4 Mix the ethanol solution, the molar ratio of Ba ions and Ti ions is 3:1, magnetically stir at 75°C for 30min to obtain a milky white turbid solution, pour the milky white turbid solution into the polytetrafluoroethylene cup in the autoclave, and control the filling The temperature is 70% (the volume of the polytetrafluoroethylene container is 100ml), and then the reaction kettle is put into a vacuum oven with a temperature adjusted in advance to carry out the hydrothermal reaction. Wherein, the hydrothermal reaction temperature is first raised to 80-100° C. and kept for 10-20 hours, then raise...

Embodiment 2

[0099] Add the first solvent and dispersant to the high tetragonal phase barium titanate powder obtained in Example 1, and obtain a white suspension with good dispersibility, ie a premix, by rolling. The first solvent is a mixture of absolute ethanol and methyl ethyl ketone at a volume ratio of 1:1, the dispersant is 3wt% castor oil, the tumbling speed is 250 rpm, and the tumbling time is 20 h. Wherein, the mass ratio of the high tetragonal phase barium titanate powder, the dispersant and the first solvent is 40:0.83:44.

[0100]Add a plasticizer, a binder and a second solvent to the above white suspension, and perform a second rolling mill. Among them, the plasticizer is dioctyl terephthalate (G200), the binder is polyvinyl butyral (PVB), and the second tumbling time is 12 hours, and the second solvent is absolute ethanol and butyral. The volume ratio of ketone is 1:1 mixed solution, the mass ratio of high tetragonal phase barium titanate powder, plasticizer, binder and seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Grain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com