Water-electricity hybrid condensation type intelligent control cooling tower

An intelligent control and cooling tower technology, applied in the field of cooling towers, can solve the problems of large diameter of atomized particles, reduce cooling water temperature, evaporation water loss, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

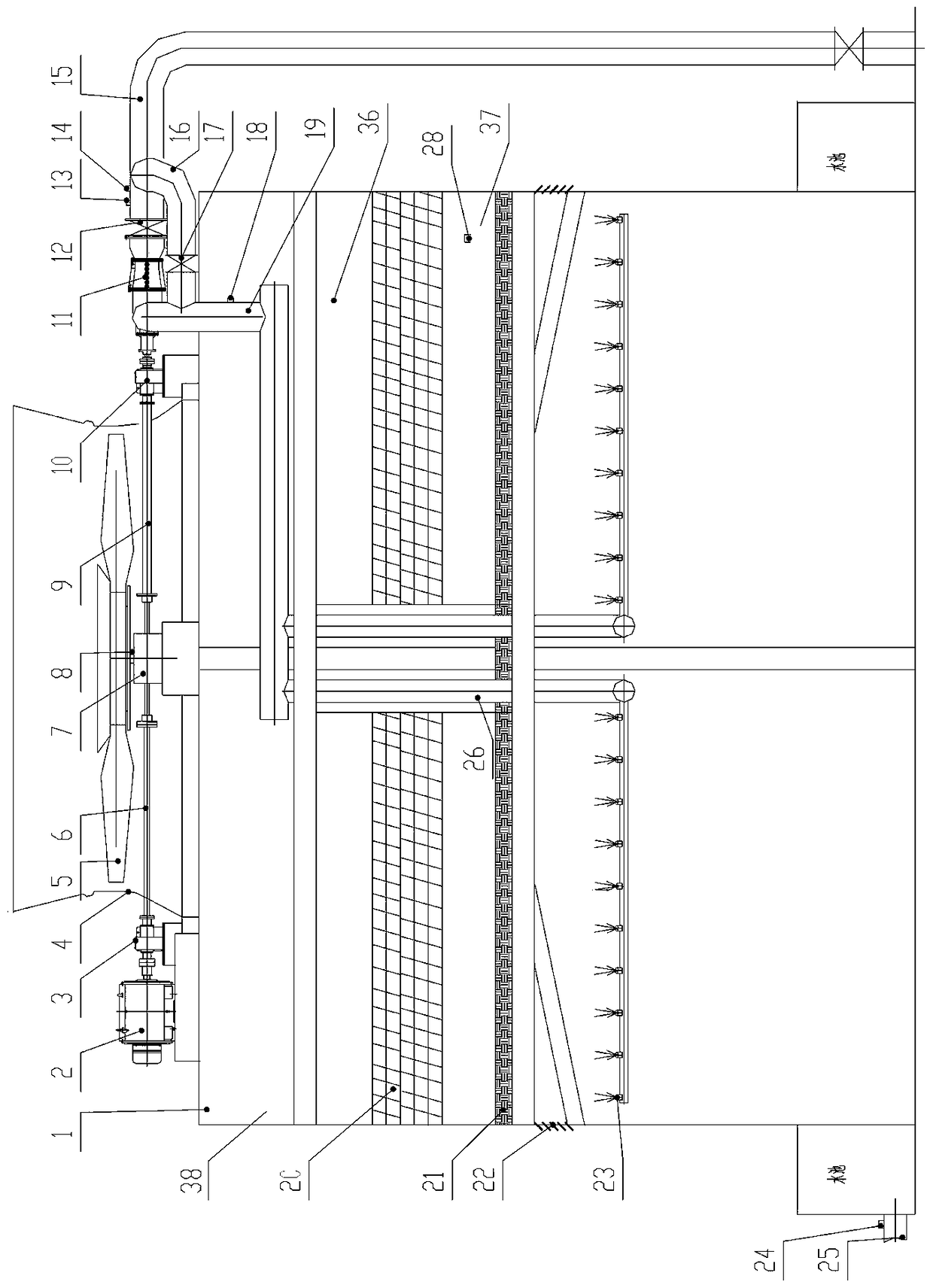

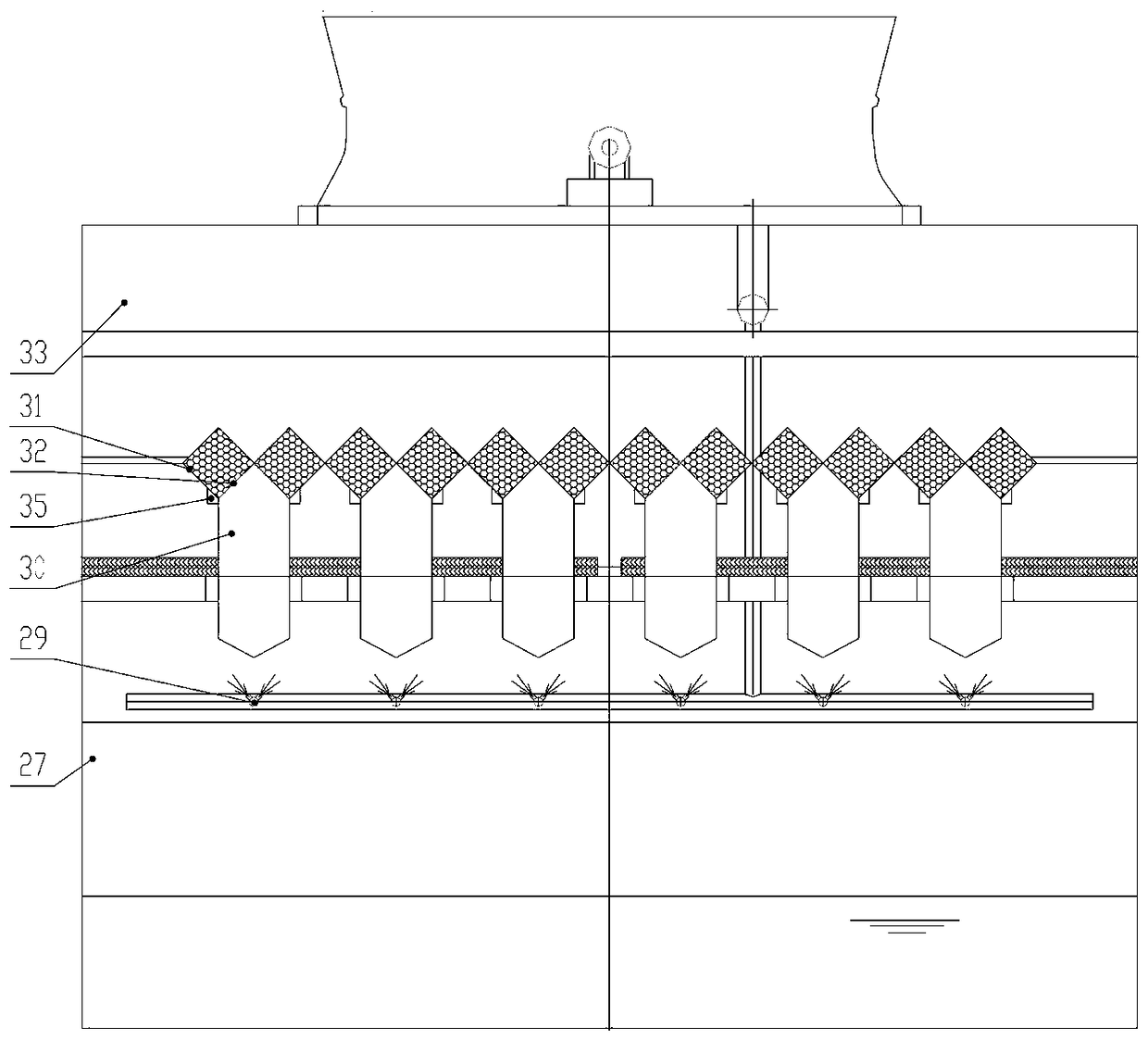

[0031] Such as Figure 1-2 As shown, a hydroelectric mixed condensing intelligent control cooling tower of the present invention is provided with a water turbine 11 and a spray pipe 23 connected to the water turbine 11. The water turbine 11 drives the fan 5 and is arranged on the upper end of the tower body or on the tower body , the spray pipe 23 is arranged at the lower end of the water turbine 11, and sprays through the water pressure difference at the water outlet end of the water turbine 11, or through the surplus pressure at the water outlet end of the water turbine 11;

[0032] The upper end of the spray pipe 23 is equipped with a water receiver 21, and the upper end of the water receiver 21 is equipped with a dry and wet air condensation recovery device 20, and the water collector 21 and the dry and wet air condensation recovery device 20 are reserved The first space 37, the first space 37 accommodates the wet hot water gas discharged from the water eliminator 21, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com