Planar strip-type nano thermoelectric generator for microcontroller

A thermoelectric generator and microcontroller technology, applied in thermoelectric devices, thermoelectric device components, circuits, etc., can solve the problems of memory bandwidth restriction core expansion, high power consumption heat loss, reliability degradation, etc., to improve thermoelectric power generation. The effect of high efficiency, high reliability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

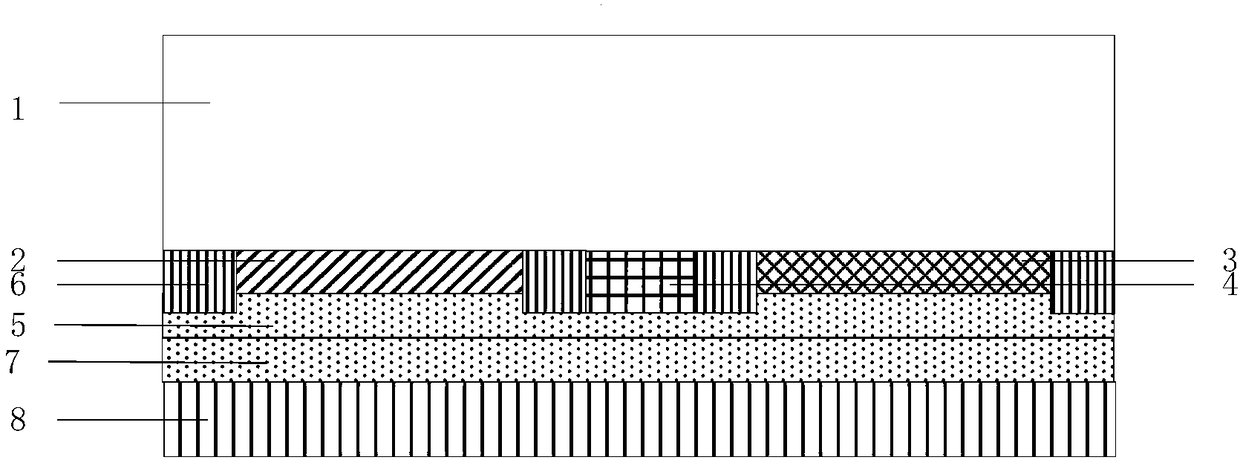

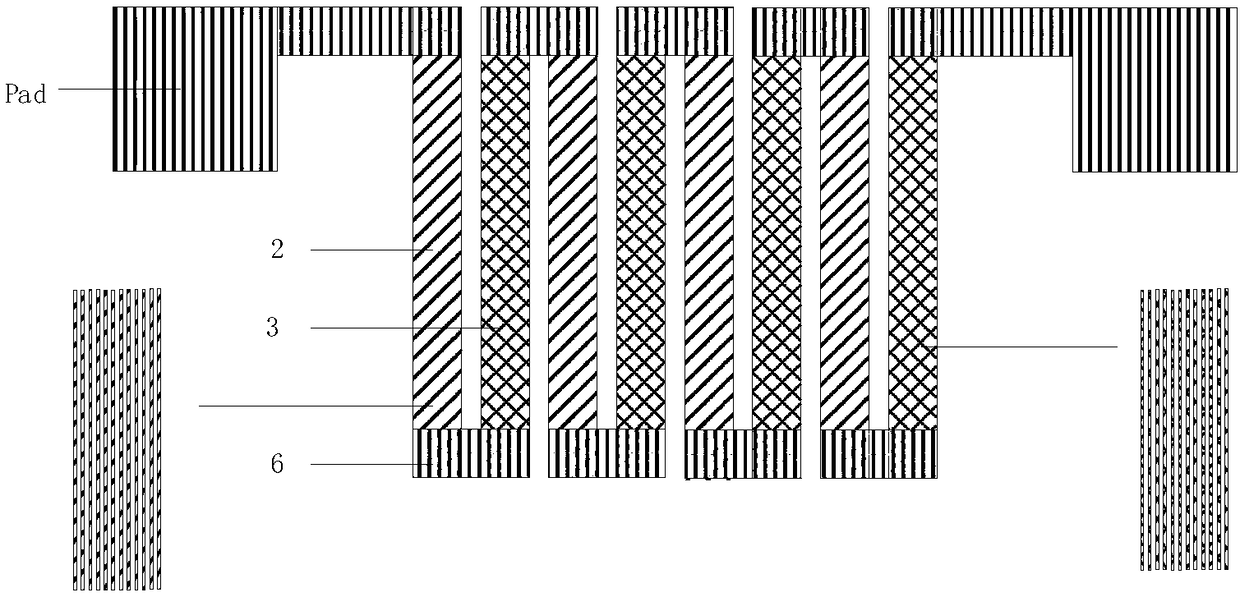

[0019] see Figure 1-2 , the present invention proposes a planar elongated nanothermoelectric generator for a microcontroller. An N-type silicon substrate 1 is selected, the phosphorus doping concentration is 1.0E15cm-3, and the resistivity is about 2Ωcm. Double-sided polishing is carried out before production, and soaked in 0.55% HF acid solution to remove impurities such as metal particles. Then, a layer of polysilicon with a thickness of 2um is grown by LPCVD, coated with photoresist, and the doping windows of the P-type thermoelectric arm and the N-type thermoelectric arm are photoetched, and the corresponding regions of the polysilicon are respectively doped with N-type phosphorus ions and After P-type boron ion doping, a P-type thermoelectric arm 2 and an N-type thermoelectric arm 3 are formed. Next, spin-coat a layer of polyimide w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com