Preparation method of high-efficiency bone repair material

A high-efficiency technology for bone repair, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problem of low efficiency of bone repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

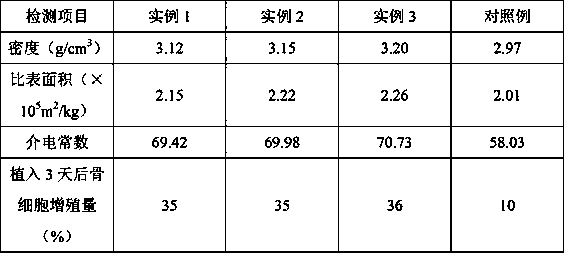

example 1

[0021] Mix calcium chloride, barium chloride and deionized water at a mass ratio of 3:1:20 to obtain a mixed solution, then mix the mixed solution with ethylenediaminetetraacetic acid at a mass ratio of 15:1 and put it into an ultrasonic oscillator In the process, react with ultrasonic oscillation at a frequency of 25kHz for 1h to obtain a self-made complexing solution for subsequent use; mix anhydrous ethanol and phosphorus pentoxide in a mass ratio of 15:1 and add them to the reaction kettle, first at a speed of 200r / min Stir and mix for 20 minutes to obtain a mixed solution, then adjust the pH of the mixed solution to 9.0 with a mass fraction of 20% ammonia water to obtain a precursor solution; drop the spare self-made complex solution into the above precursor solution at a mass ratio of 1:3, and heat Under the microwave irradiation treatment with a power of 300W for 12h, after the treatment, it was placed at a temperature of 4°C and aged for 24h, and after the aging was com...

example 2

[0023] Mix calcium chloride, barium chloride and deionized water at a mass ratio of 3:1:20 to obtain a mixed solution, then mix the mixed solution with ethylenediaminetetraacetic acid at a mass ratio of 15:1 and put it into an ultrasonic oscillator In the process, react with ultrasonic oscillation at a frequency of 28kHz for 1h to obtain a self-made complexing solution for subsequent use; mix absolute ethanol and phosphorus pentoxide in a mass ratio of 15:1 and then add them to the reaction kettle, first at a speed of 250r / min Stir and mix for 25 minutes to obtain a mixed solution, then adjust the pH of the mixed solution to 9.3 with a mass fraction of 20% ammonia water to obtain a precursor solution; drop the spare self-made complex solution into the above precursor solution according to a mass ratio of 1:3, and heat at 65°C Under microwave irradiation with a power of 350W for 14h, after the treatment, place it at a temperature of 5°C for 26h, and filter and separate to obtain...

example 3

[0025]Mix calcium chloride, barium chloride and deionized water at a mass ratio of 3:1:20 to obtain a mixed solution, then mix the mixed solution with ethylenediaminetetraacetic acid at a mass ratio of 15:1 and put it into an ultrasonic oscillator In the process, react with ultrasonic oscillation at a frequency of 30kHz for 2h to obtain a self-made complexing solution for subsequent use; mix absolute ethanol and phosphorus pentoxide in a mass ratio of 15:1 and then add it to the reaction kettle, firstly at a speed of 300r / min Stir and mix for 30 minutes to obtain a mixed solution, and then adjust the pH of the mixed solution to 9.5 with a mass fraction of 20% ammonia water to obtain a precursor solution; drop the spare self-made complex solution into the above precursor solution at a mass ratio of 1:3, and heat at 70°C Under microwave irradiation with a power of 400W for 15h, after the treatment, place it at a temperature of 6°C and let it age for 30h. After the aging, filter a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com