Separation method of oil-water emulsion

A separation method and emulsion technology, applied in the field of emulsion separation, can solve the problems of small adsorption capacity and limitation of separation membrane, and achieve the effects of fast separation speed, high recycling rate and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 0.180mL (200mg) of polyethylene glycol diacrylate (number average molecular weight 600), 100mg polydivinylbenzene particles (average particle size 4μm), 0.5μL N,N-dimethylaniline and 1.0mg peroxide Benzoyl was added to 1.1 mL of dimethyl sulfoxide and mixed evenly. After passing through nitrogen to deoxygenate, it was transferred to a syringe and sealed. The reaction temperature was controlled at -18°C and reacted for 48 hours. The obtained product is fully washed with the elution solvent ethanol, and then dried to obtain a composite ultra-macroporous polymer.

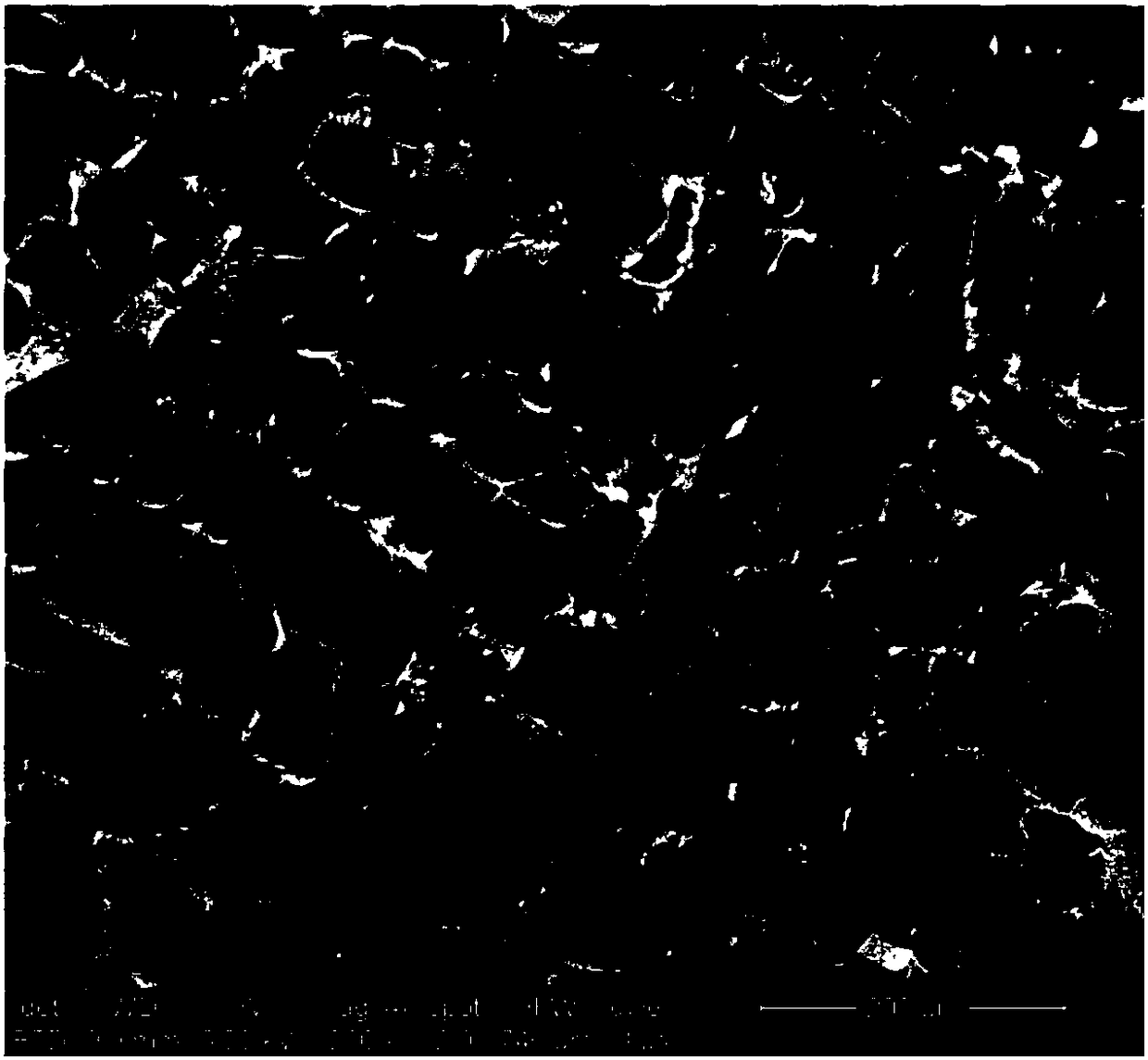

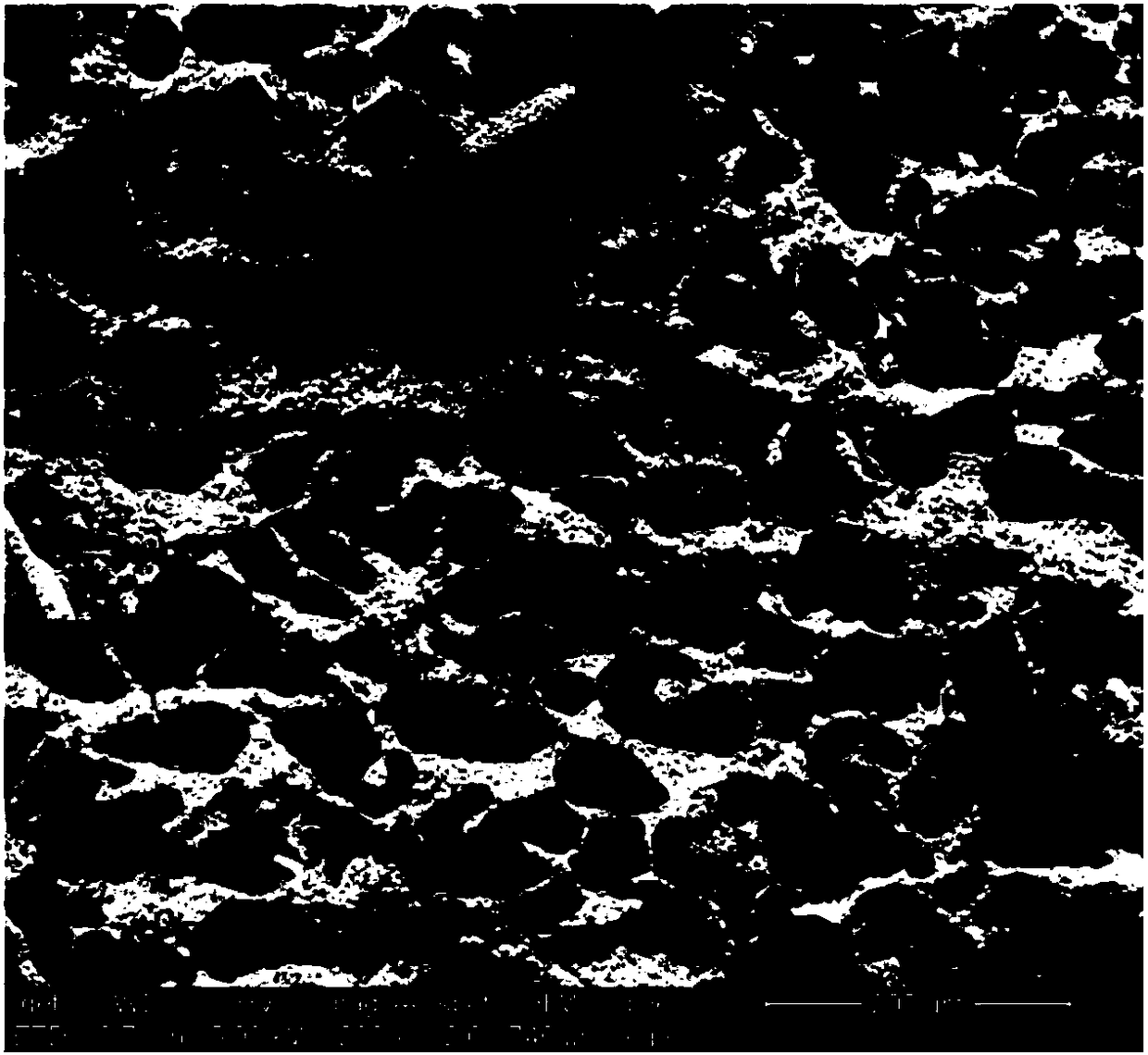

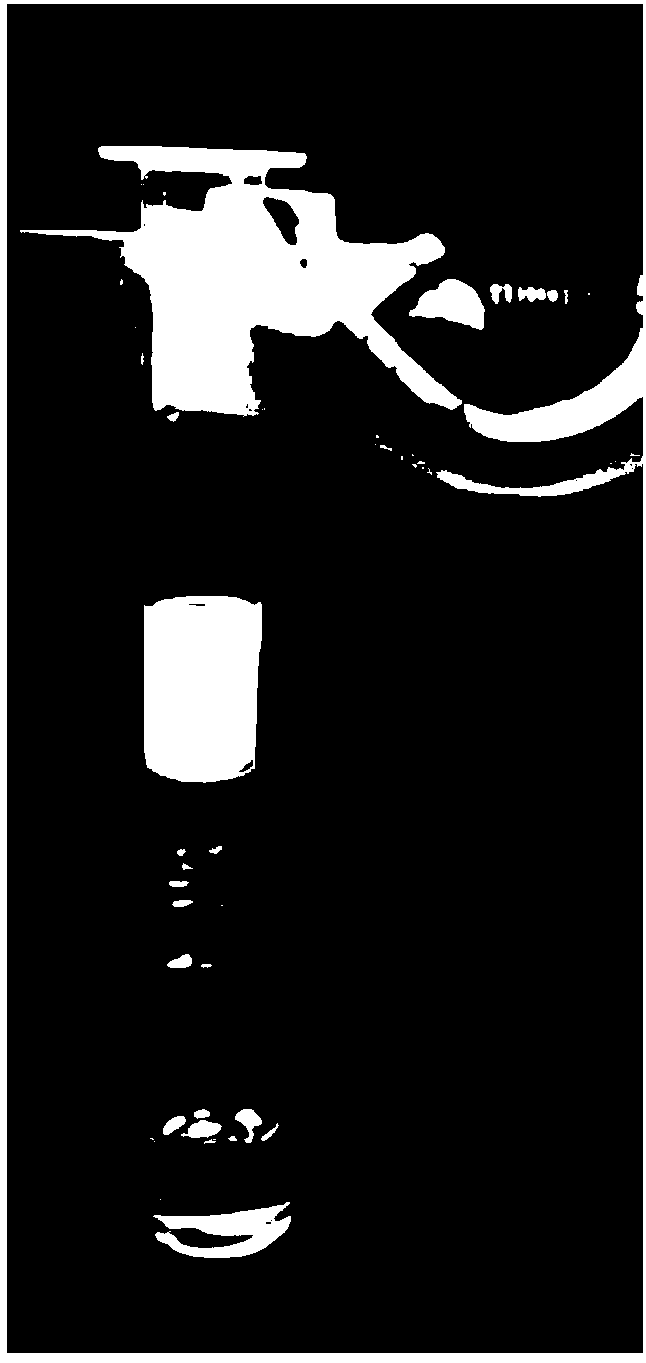

[0034] The scanning electron microscope picture of the composite ultra-macroporous polymer that the present embodiment makes is as follows figure 2 As shown, the schematic diagram of the oil-water emulsion separation process is shown in image 3 shown.

[0035] Put the obtained composite ultra-macroporous polymer material in a syringe, add water to swell and balance for 2 hours, add 1mL oil-water emulsio...

Embodiment 2

[0038] Take 0.36mL (400mg) of polyethylene glycol diacrylate (number average molecular weight 600), 40mg polydivinylbenzene particles (average particle size 4μm), 0.2μL N,N-dimethylaniline and 0.4mg peroxide Benzoyl was added to 1.6 mL of dimethyl sulfoxide and mixed well. After passing through nitrogen to deoxygenate, it was transferred to a syringe and sealed. The reaction temperature was controlled at -18°C and reacted for 48 hours. The obtained product is fully washed with the elution solvent ethanol, and then dried to obtain a composite ultra-macroporous polymer.

[0039] Put the obtained composite ultra-macroporous polymer material in a syringe, add water to swell and balance for 2 hours, add 1mL oil-water emulsion from the upper part of the column tube, and the oil-water emulsion can flow through the polymer column material only by gravity, and the water can pass through the polymer column smoothly. material, it takes 1 minute, while the oil is retained in the column ma...

Embodiment 3

[0041] Take 0.135mL (150mg) of polyethylene glycol diacrylate (number average molecular weight 600), 150mg polydivinylbenzene particles (average particle size 4μm), 0.8μl N,N-dimethylaniline and 1.5mg peroxide Benzoyl was added to 1.09 mL of dimethyl sulfoxide and mixed evenly. After passing through nitrogen to deoxygenate, it was transferred to a syringe and sealed. The reaction temperature was controlled at -18°C and reacted for 48 hours. The obtained product is fully washed with the elution solvent ethanol, and then dried to obtain a composite ultra-macroporous polymer.

[0042]Put the obtained composite ultra-macroporous polymer material in a syringe, add water to swell and balance for 2 hours, add 1mL oil-water emulsion from the upper part of the column tube, and the oil-water emulsion can flow through the polymer column material only by gravity, and the water can pass through the polymer column smoothly. material, it takes 1 minute, while the oil is retained in the colum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com