Hollow lost foam casting mold and manufacturing method thereof

A lost foam, hollow technology, applied in the field of metal casting molds, can solve the problem of scrapped processing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

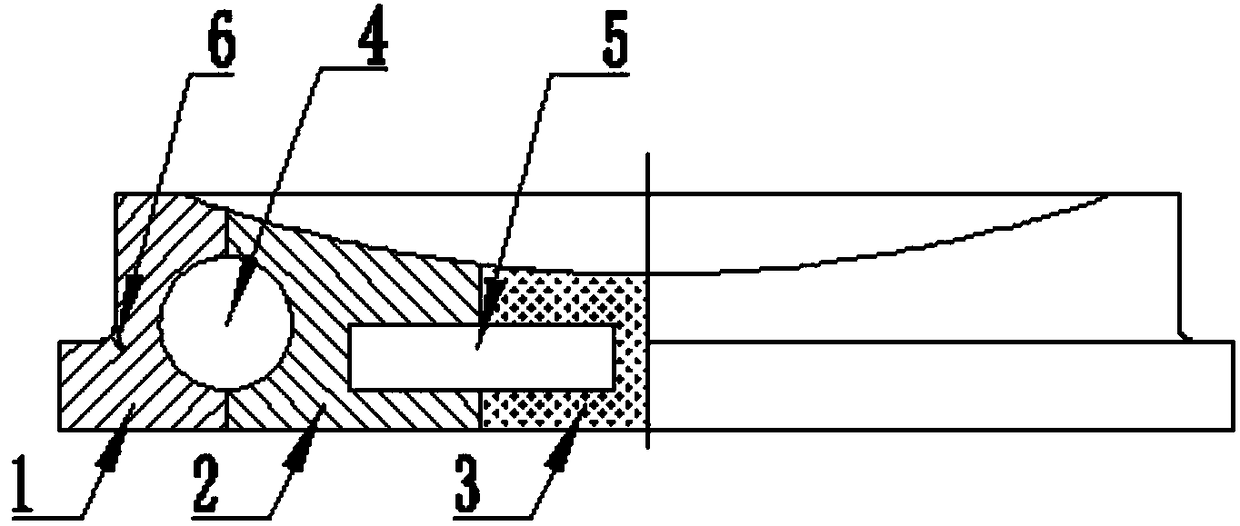

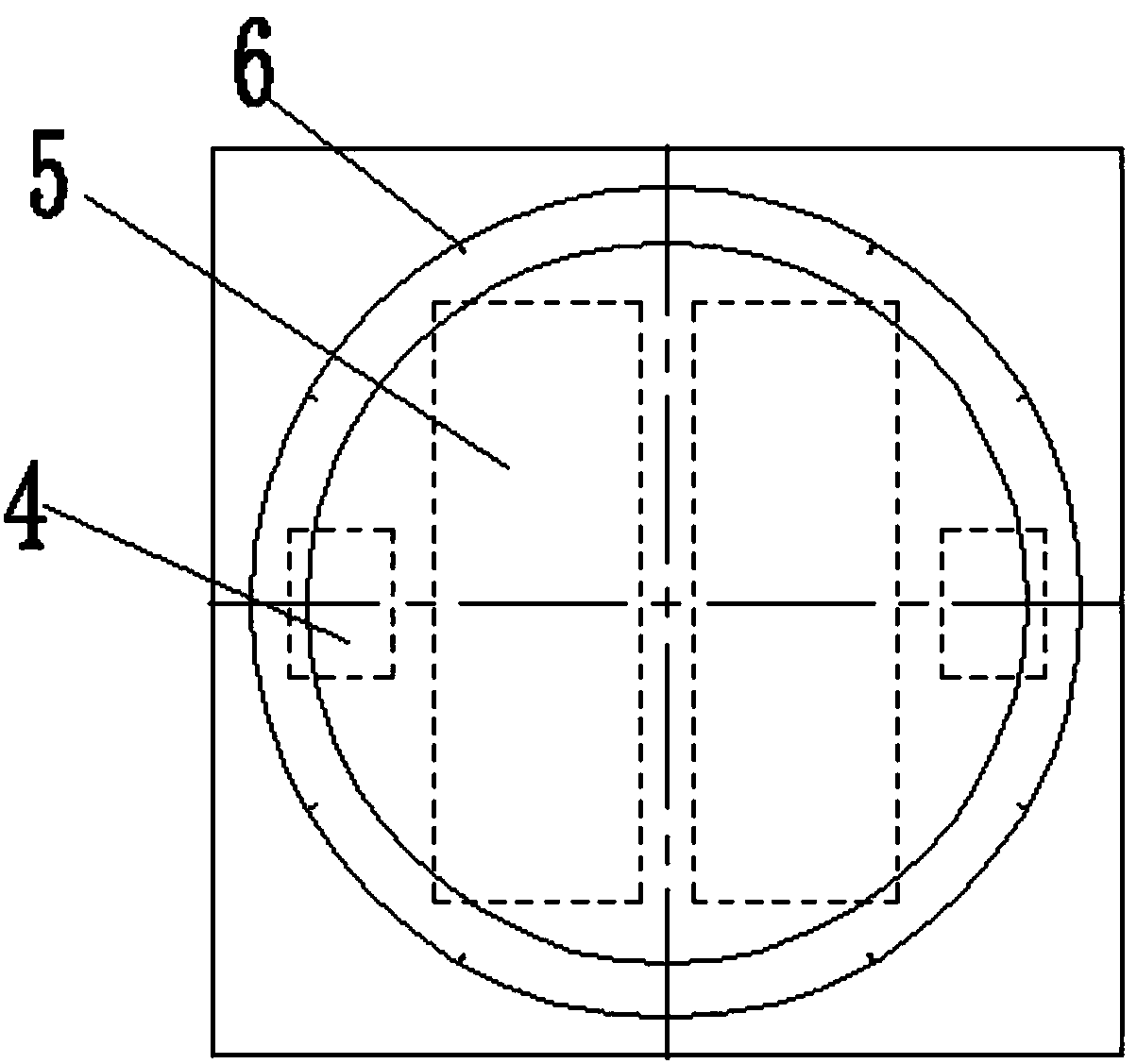

[0050] The present invention also provides a method for preparing the hollow lost foam described in the above technical solution, comprising the following steps:

[0051] (1) Use the simulation analysis software to carry out the structural design of the hollow lost foam, and obtain the hollow lost foam model composed of side forms, side forms and middle forms;

[0052] (2) according to the design scheme in the step (1), adopt foaming material to make side mold parts, side mold parts and middle mold parts respectively;

[0053] (3) connecting and assembling the side mold parts, the side mold parts and the middle mold part to obtain the prototype of the hollow lost foam;

[0054] (4) coating the outer surface of the hollow lost foam prototype with a refractory paint layer to obtain the hollow lost foam prototype;

[0055] (5) Vibrating the hollow lost foam refractory prototype in dry sand to obtain a hollow lost foam.

[0056] The invention uses simulation analysis software to...

Embodiment 1

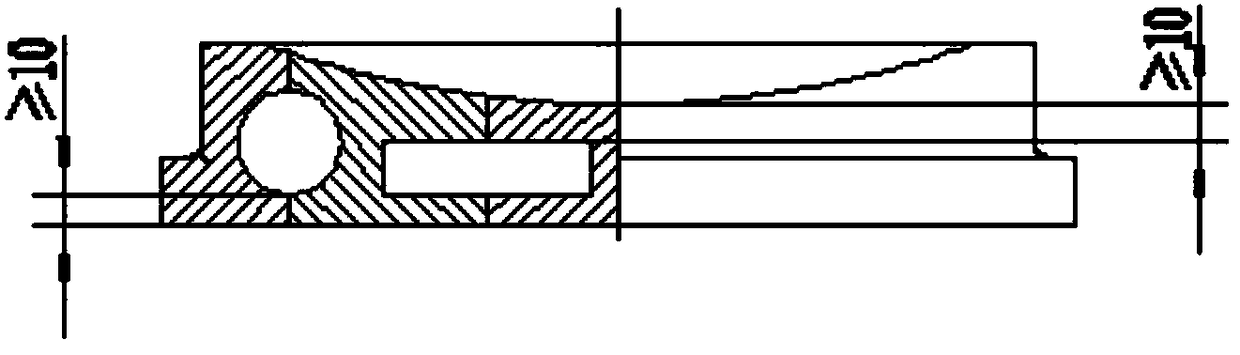

[0067] The structural design of the hollow model is carried out using simulation analysis software. The principle of the structural design is to reduce the amount of foaming material by 20% compared with the solid lost foam of the same size and structure under the premise of ensuring that the pressure resistance of the hollow model is greater than 0.1MPa.

[0068] According to the design scheme, polymethyl methacrylate foam material is used to make side mold parts, side mold parts and middle mold parts.

[0069] The components are bonded and assembled to form a hollow model of the casting.

[0070] Brush the water-based zircon powder refractory paint on the outer surface of the hollow model and dry it to obtain a 3mm thick refractory paint layer.

[0071] Embed the hollow model coated with refractory paint into dry pearl sand and form it by vibration, the vibration frequency is 50HZ, the vibration time is 3 minutes, and the vacuum negative pressure is -0.05MPa.

[0072] Pouri...

Embodiment 2

[0075] The structural design of the hollow model is carried out by using simulation analysis software. The principle of the structural design is to reduce the amount of foam material by 25% compared with the solid lost foam of the same size and structure under the premise of ensuring that the pressure resistance of the hollow model is greater than 0.1MPa.

[0076] According to the design scheme, polymethyl methacrylate foam material is used to make side mold parts, side mold parts and middle mold parts.

[0077] The components are bonded and assembled to form a hollow model of the casting.

[0078] Brush the water-based zircon powder refractory paint on the outer surface of the hollow model and dry it to obtain a 3mm thick refractory paint layer.

[0079] Embed the hollow model coated with refractory paint into dry pearl sand and form it by vibration, the vibration frequency is 40HZ, the vibration time is 4 minutes, and the vacuum negative pressure is -0.04MPa.

[0080] Pouri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com