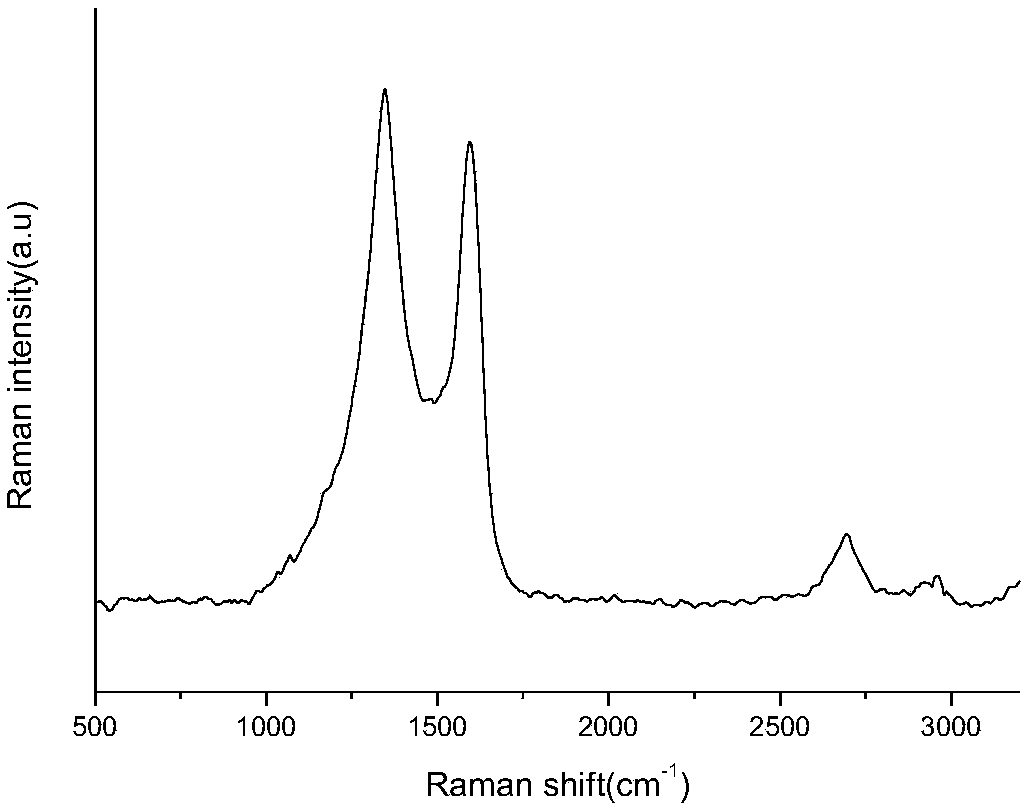

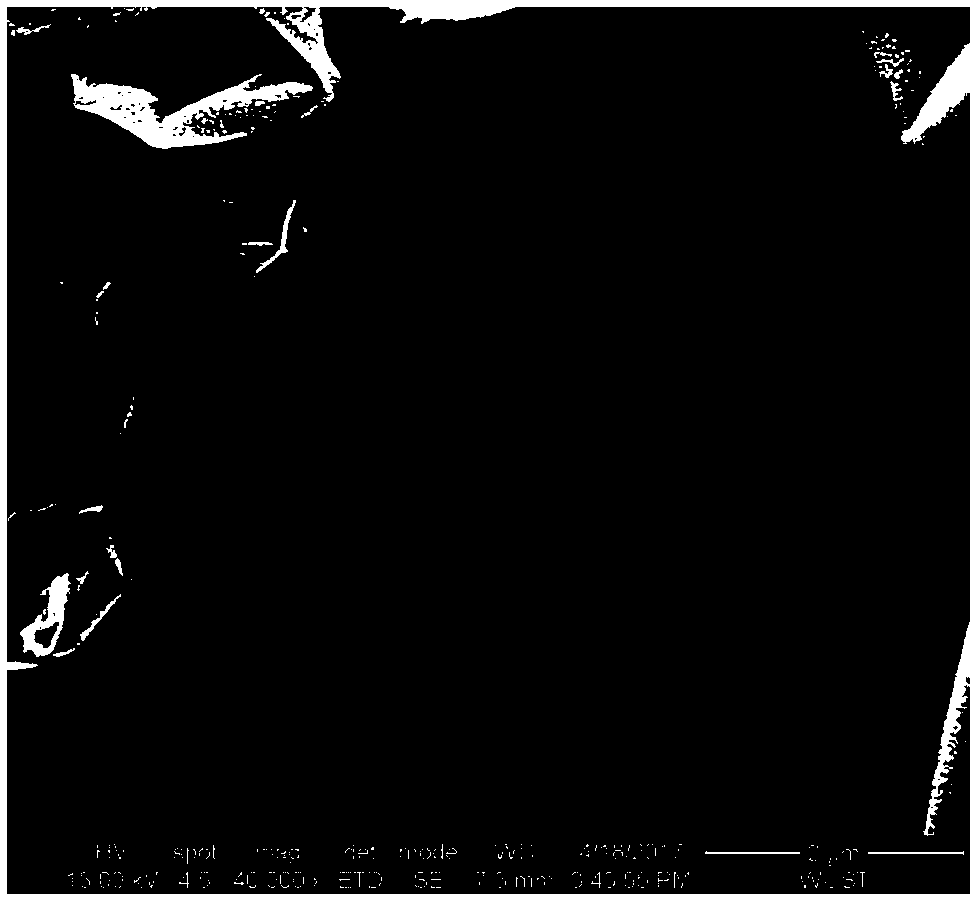

Method for separating and purifying graphene from pyrolysis carbon

A high-temperature pyrolysis, separation and purification technology, applied in the field of graphene, can solve the problems of high technical requirements and difficulty in obtaining pure graphene, and achieve the effects of simple operation, wide application range and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Get the phenolic resin carbonization product 1g that contains graphene and pulverize into the powder that is less than 0.1mm with pulverizer, get the DMF solvent dissolving of 100mL again and disperse half an hour with high-speed disperser to obtain mixed solution, described mixed solution centrifugation 30min, control The rotating speed of centrifuge is 5000r / min, collects graphene suspension after removing precipitation; After described graphene suspension is dispersed at high speed for half an hour, carry out centrifugation 20min again, the rotating speed of control centrifuge is 5000r / min, filter and filter After the supernatant is dried, graphene with a layer number of 1 to 10 layers can be prepared, and the recovery rate can reach 48.7%.

Embodiment 2

[0051] Take 1g of phenolic resin carbonization product containing graphene and grind it into a powder smaller than 0.1mm with a pulverizer, then take 100mL of DMF solvent and 0.1g potassium sodium tartrate to dissolve the above powder, and disperse it with a high-speed disperser for half an hour to get mixed Solution, centrifuge the mixed solution for 30min, control the rotating speed of the centrifuge to 5000r / min, and collect the graphene suspension after removing the precipitate; disperse the graphene suspension at a high speed for half an hour and then perform centrifugation for 15min, control the centrifugation The rotating speed of the machine is 5000r / min, and the graphene with a layer number of 1 to 10 layers is prepared by filtering and drying the supernatant, and the recovery rate can reach 66.3%.

Embodiment 3

[0053] Get the carbonized product 1g of the phenolic resin that contains graphene and coal tar pitch (the mass ratio between the two is 1:1) and use pulverizer to be pulverized into the powder that is less than 0.1mm, then take the NMP solvent of 100mL to dissolve the above-mentioned powder, after dissolving Disperse with a high-speed disperser for half an hour to obtain a mixed solution, centrifuge the mixed solution for 20 minutes, control the rotating speed of the centrifuge to 5000r / min, and collect the graphene suspension after removing the precipitate; disperse the graphene suspension at a high speed for half an hour Then centrifuge for 15 minutes, control the rotating speed of the centrifuge to 5000r / min, filter and dry the supernatant to prepare graphene with 1-10 layers, and the recovery rate can reach 63.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com