Preparation method of transparent nano-crystal composite glass optical fibers

A nanocrystal composite, glass fiber technology, applied in glass manufacturing equipment, lasers, manufacturing tools and other directions, can solve the problems of affecting optical fiber optical properties, fluorescent nanocrystal melting, complex process, etc., to achieve short preparation time, improve efficiency, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] (1)Y 2 O 3 :7%Er 3+ Preparation of fluorescent nanocrystals:

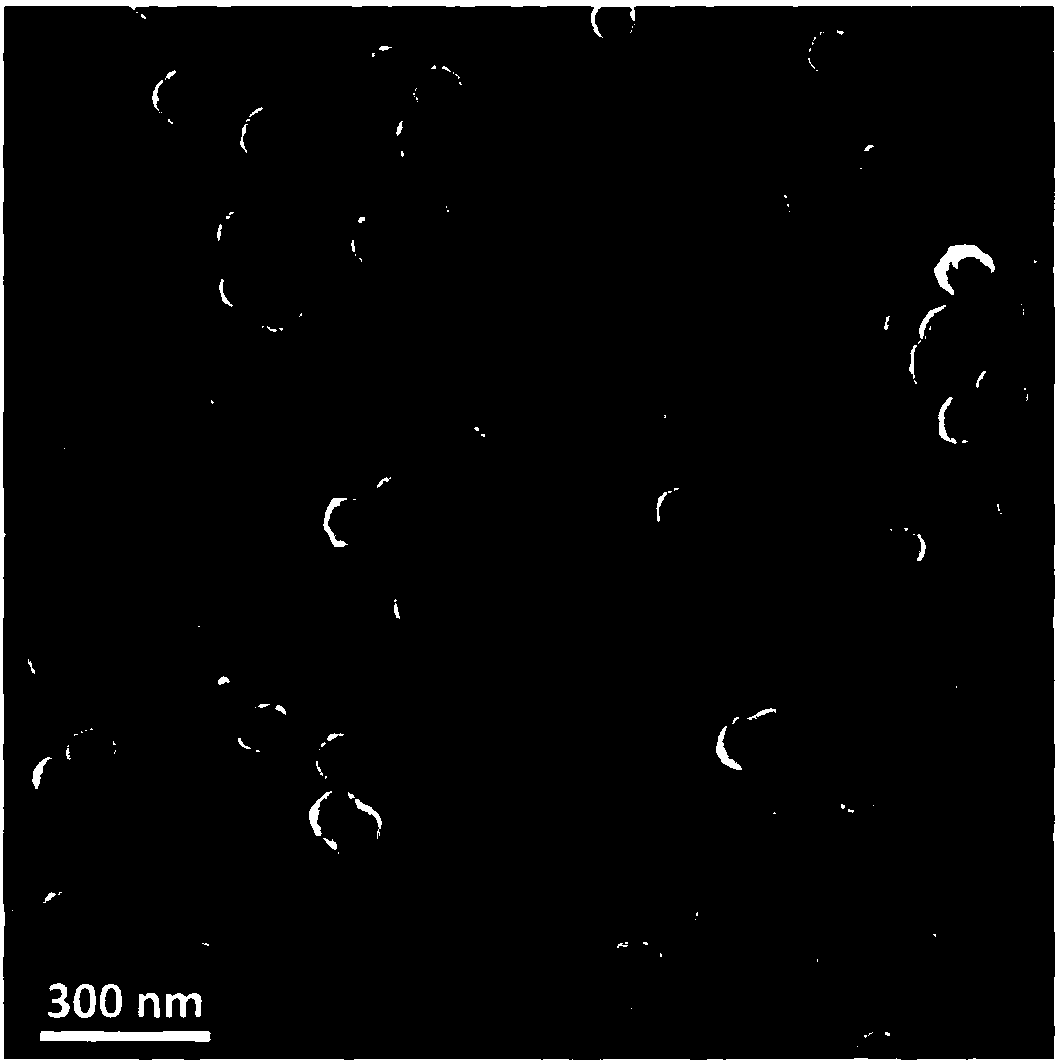

[0040] Prepared by co-precipitation method, first mix the corresponding cationic solution according to the stoichiometric ratio, and at the same time carry out magnetic stirring, add an appropriate amount of C after stirring for 10 minutes 16 h 33 (CH 3 ) 3 NBr(CTAB). Then the mixed solution was ultrasonically placed at a frequency of 80KHz for 15min, and an appropriate amount of CO(NH 2 ) 2 And ultrasonicated at the same frequency for 1 h, then the mixed solution was heated to 90° C. for 1.5 h to obtain a white precipitate. Then wash and centrifuge the white precipitate several times with distilled water and absolute ethanol, and dry the obtained product at 70°C for 12 hours, then place it in a box furnace and heat it at 500-1200°C for 2 hours at a rate of 3°C / min. Obtained Y 2 O 3 :7%Er 3+ The morphology of fluorescent nanocrystals is as follows figure 1 shown.

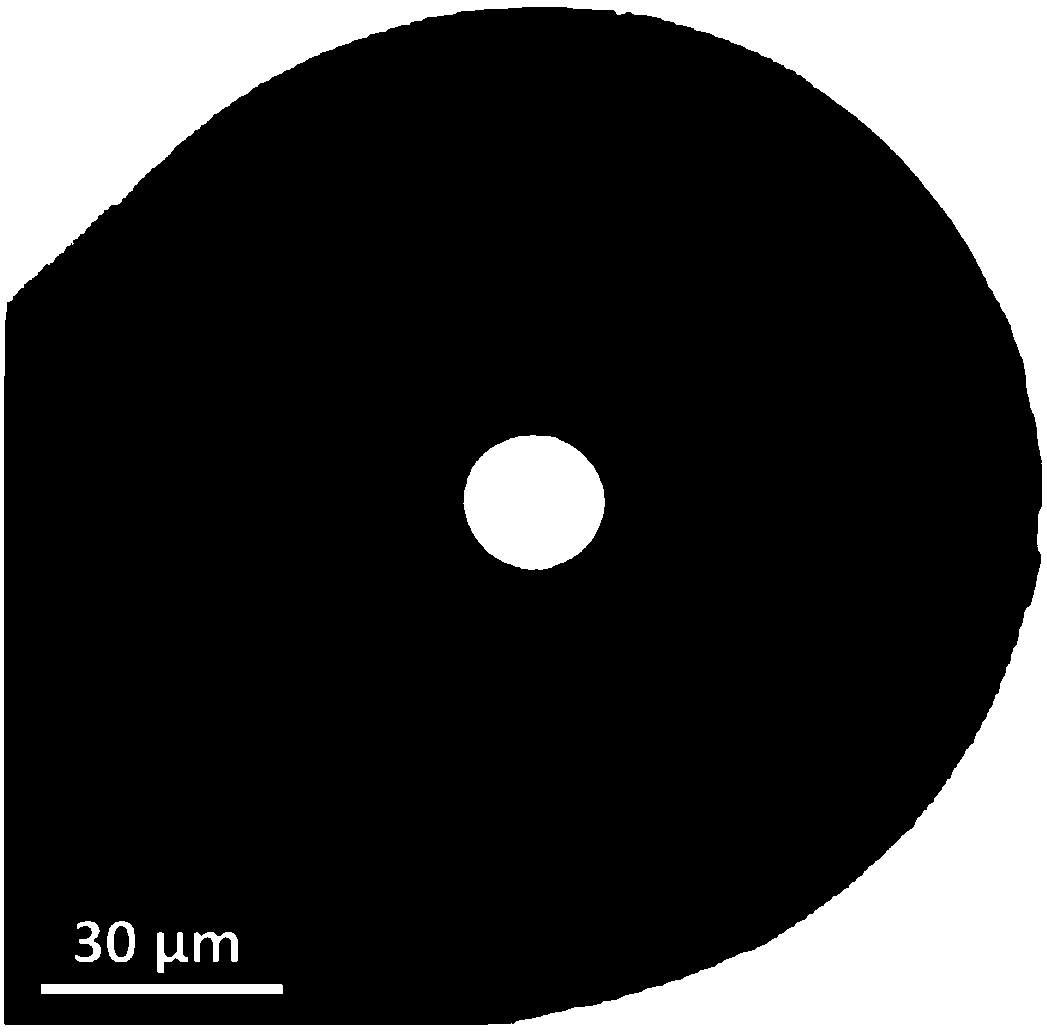

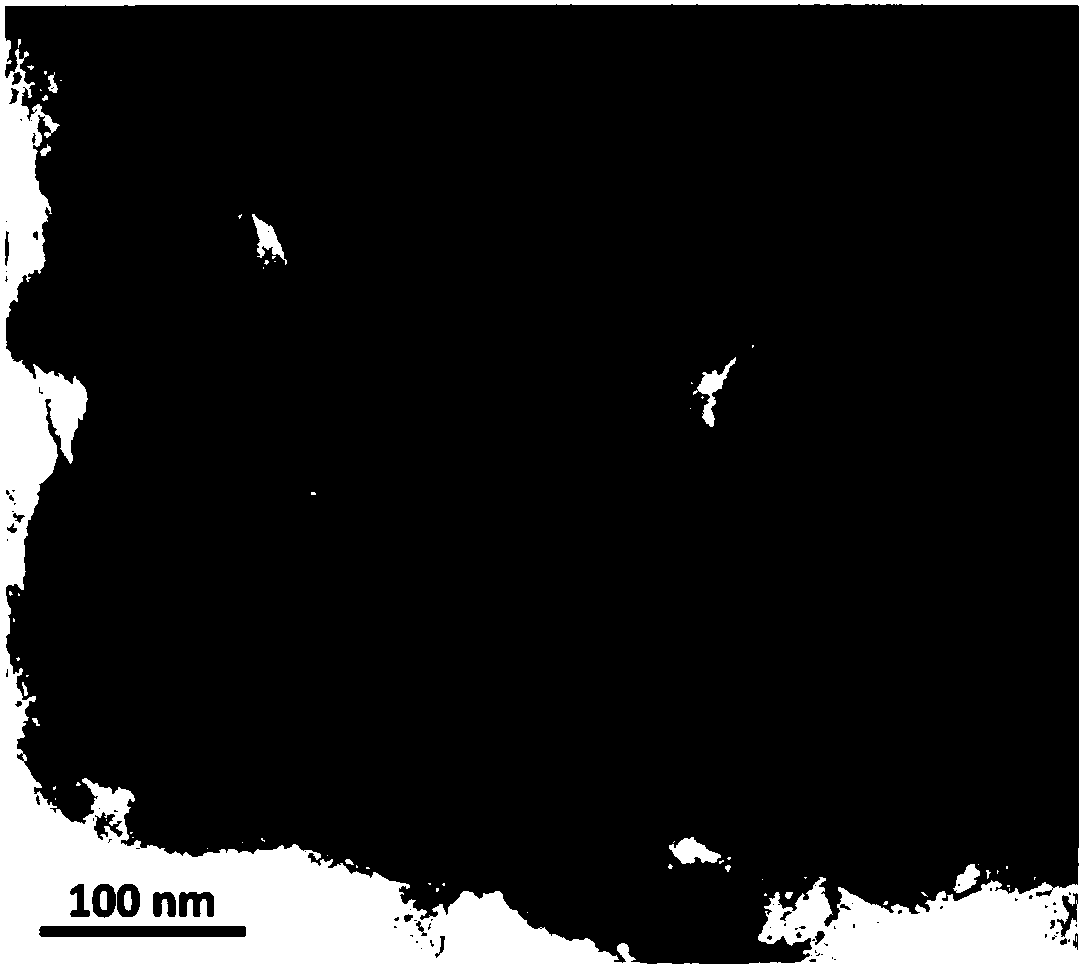

[0041] (2) Preparation of cor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap