Waterborne naphthalimide fluorescent polymer emulsion and preparation method thereof

A technology of fluorescent polymer and naphthalimide, applied in the chemical industry, can solve the problems of limited whitening effect of non-aqueous emulsion polymer, limited fluorescent whitening effect of polymer, fluorescence quenching, etc., and achieve high paper whitening. and yellowing inhibition effect, inhibiting paper yellowing and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

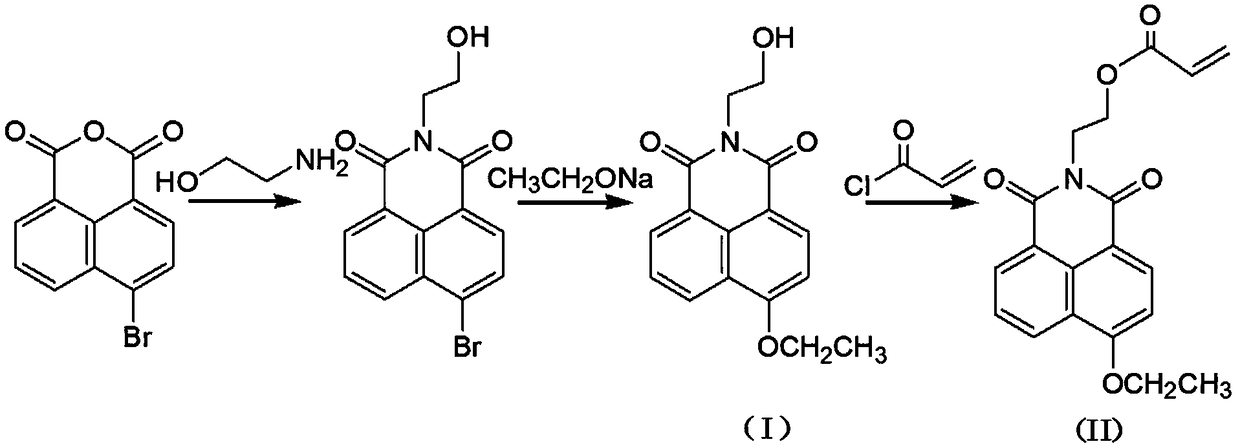

[0032] The preparation process of the above-mentioned naphthalimide fluorescent small molecules is as follows, which can be referred to (Guo Jinge, Zhang Guanghua, Xu Hailong, etc. Research on the inhibition of yellowing of water-soluble ultraviolet absorbers and naphthalimide fluorescent whitening agents [ J]. China Paper, 2012,31(10):24-28.):

[0033] React 4-bromo-1,8-naphthalene anhydride with ethanolamine (molar ratio 1:1-1:1.5) at 60-80°C for 4-6h, and then react the reaction product with sodium ethylate (molar ratio 1:1-1 : 1.5) react for 4-6h (50-70°C), vacuum filter after the reaction, wash with deionized water, and dry to constant weight at 40°C to obtain naphthalimide fluorescent small molecule (formula I), see figure 1 .

[0034] The preparation method of the above-mentioned double bonded functional monomer is as follows:

[0035]Dissolve 0.01mol 2,4-dihydroxy-benzophenone or 2,2,6,6-tetramethylpiperidinamine in 40mL of dichloromethane, place in a three-necked fl...

Embodiment 1

[0037] Weigh 0.008mol of naphthalimide fluorescent small molecule into a 250mL three-neck flask, add 40mL of dichloromethane, and stir for 30min under ice bath conditions to fully dissolve the naphthalimide fluorescent small molecule, and then slowly drop an appropriate amount of acryloyl chloride ( The molar ratio of naphthalimide fluorescent small molecule to acryloyl chloride = 1:1.2), continue to stir for 30 minutes to make it evenly dispersed, heat up to 45°C, reflux with a straight condenser tube, and react overnight in the dark. A clear yellow liquid was obtained, and after rotary evaporation and drying (at a temperature of 40-45° C.), yellow needle-like crystals were obtained, i.e. small molecule fluorescent monomers (formula II), such as figure 1 shown.

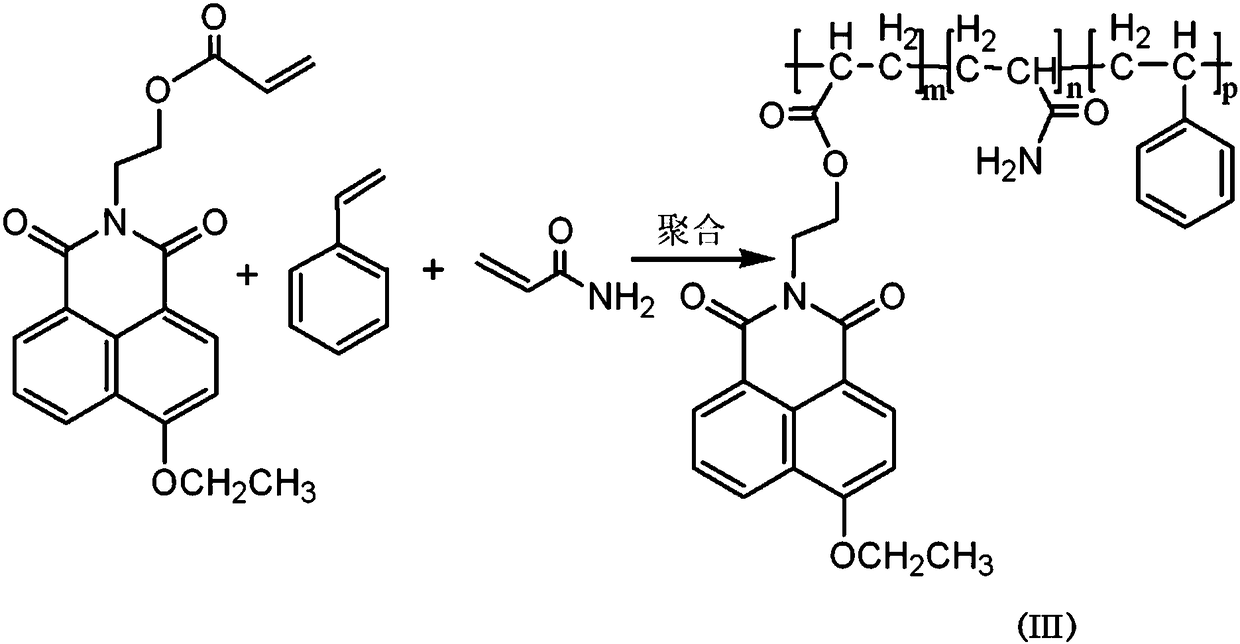

[0038] Weigh 0.3g of cetyltrimethylammonium bromide (CTMAB) and dissolve it in 25mL of water, stir evenly, place in a three-necked flask, then slowly raise the temperature to 70°C, dissolve 0.3g of small molecule flu...

Embodiment 2

[0050] Weigh 0.008mol of naphthalimide fluorescent small molecule into a 250mL three-necked flask, add 40mL of dichloromethane, stir vigorously in ice bath for 30min, then slowly add appropriate amount of acryloyl chloride (naphthalimide fluorescent small molecule and acryloyl chloride Molar ratio = 1:1.2), continue to stir for 30 minutes, heat up to 45°C, reflux with a straight condenser tube, and react overnight in the dark to obtain a clear yellow liquid, which is dried by rotary evaporation (at a temperature of 40-45°C) to obtain yellow Needle-like crystals, that is, small molecule fluorescent monomers.

[0051] Weigh 0.2g of cationic emulsifier cetyltrimethylammonium bromide CTMAB and OP-10 (mass ratio is 3:5) dissolved in 25mL of water, stir evenly, place in a three-necked flask, then slowly heat up to 70°C , Add 0.1-0.3g of small molecule fluorescent monomer, 0.1-0.3g of 2,4-dihydroxy-benzophenone monomer with double bond and 5g of styrene into the three-necked flask, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com