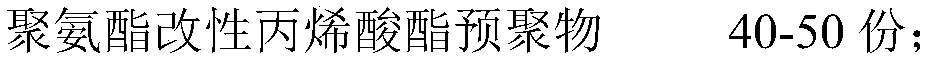

Optical cement for silver nanowire conductive film and preparation method thereof

A technology of silver nanowires and optical glue, which is applied in the field of optical glue, can solve the problems of mechanical properties and light transmittance decline, poor matching of transparent conductive films, poor water resistance, etc., to protect high-temperature and high-humidity power-on stability and improve power-on stability Sex, improve the effect of photostability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

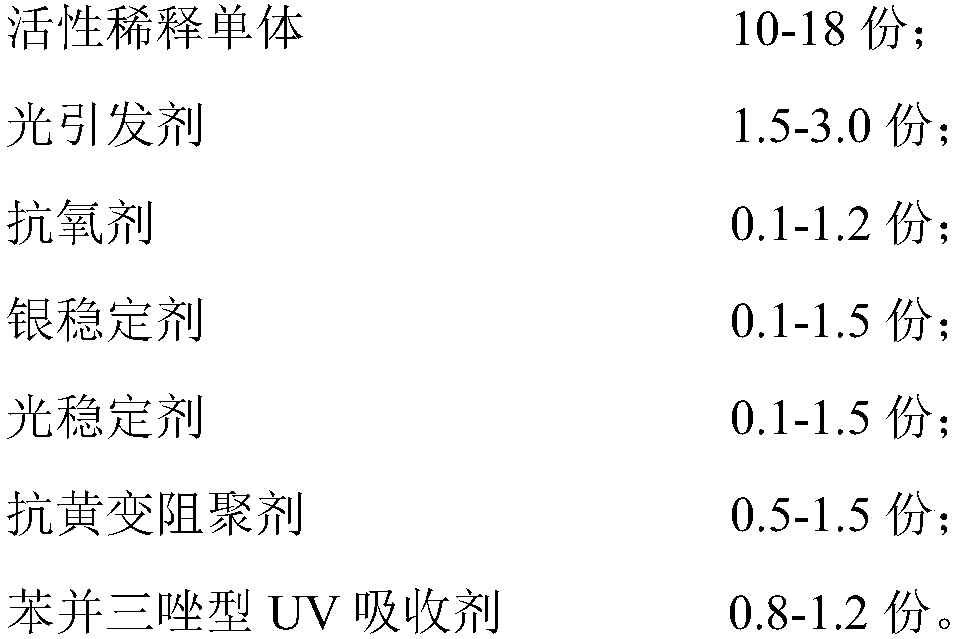

[0039] In each embodiment, see Table 1 for the composition of each raw material of the optical glue in terms of mass fraction. In addition to each raw material in Table 1, there are also three raw materials of the same content commonly used in Examples 1-5: 0.1 part, 1.5 part, and 0.5 part of light stabilizer, photoinitiator, and anti-yellowing polymerization inhibitor respectively.

[0040] The preparation method of each embodiment optical glue is as follows:

[0041] (1) Take each raw material by weight, then mix and stir to disperse evenly to obtain a pre-coating slurry;

[0042] (2) Use a slit coater to coat the pre-coating slurry (coating speed is 20m / min) on a layer of release film to form a coating layer with a thickness of 150 μm, and then bond another coating layer on the coating layer A layer of release film to obtain the first product of optical adhesive;

[0043] (3) Curing the first product of optical glue by UVLED lamp (curing energy 800mJ / cm 2 ), that is, to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com