Baby formula milk powder with effect of protecting teeth and preparation method of baby formula milk powder

A technology for formula milk powder, infants and young children, applied in the direction of bacteria and applications used in milk preparations and food preparation, can solve the problems of hindered nutrient absorption function of babies, loss of chewing function, affecting growth and development, etc., to improve oral flora. Balance, promote digestion and absorption, beneficial effects of tooth growth and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

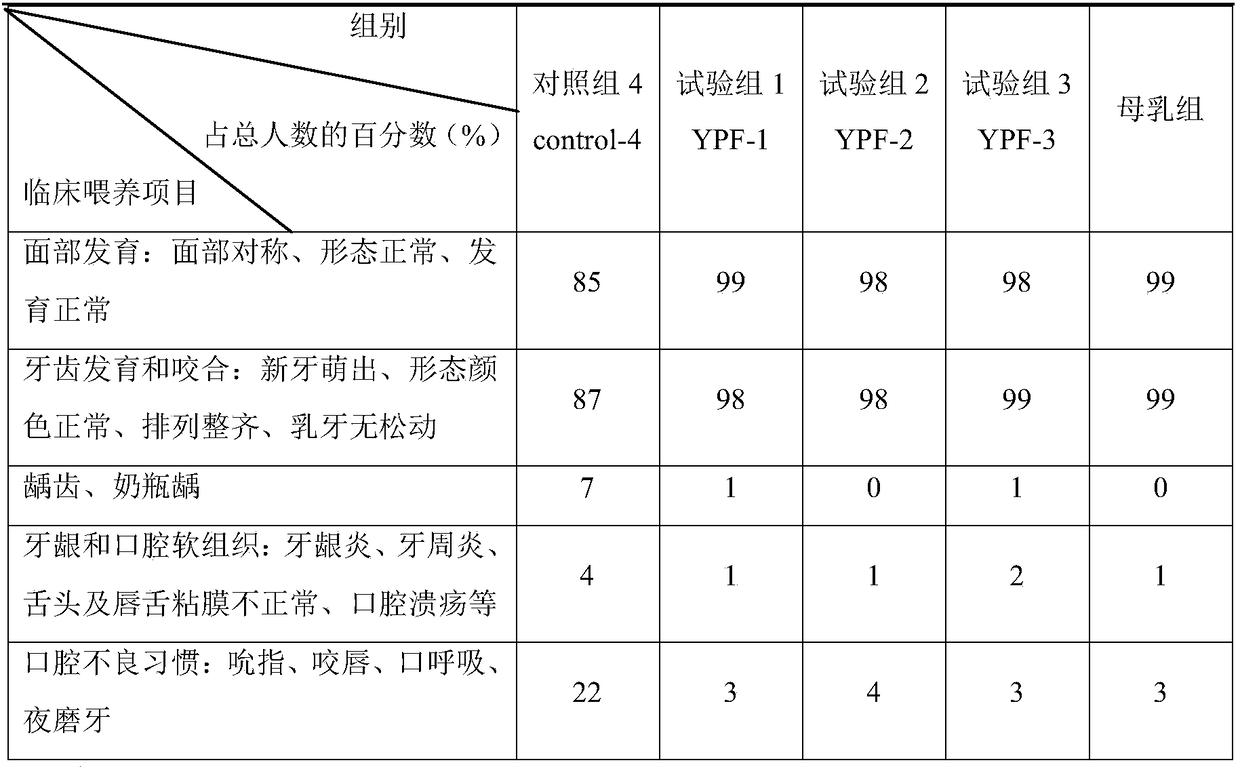

Examples

Embodiment 1

[0038] A kind of infant formula milk powder of tooth protection, its raw material comprises following component by weight percentage:

[0039] Desalted goat whey powder 45%, whole goat milk powder (fresh goat milk dry matter is calculated as 12.0%) 22.5%, mixed vegetable oil 21%, concentrated goat whey protein powder 1.5%, glycomacropeptide 1%, lactose 5.16%, Human milk oligosaccharides 2.0%, DHA 0.2%, ARA 0.4%, complex nucleotides 0.02%, lactoferrin 0.025%, taurine 0.025%, L-carnitine 0.02%, multivitamin premix 0.25%, Compound mineral premix 0.7%, Lactobacillus rhamnosus LGG freeze-dried powder (its content 1×10 10 CFU / g) 0.2%.

[0040] The mixed edible vegetable oil is formed by mixing the following components and weight percentages: 40% sunflower oil, 30% coconut oil, 20% soybean oil, and 10% palm oil.

[0041] The human milk oligosaccharides are mixed with the following components and weight percentages: 65% of 2'-fucosyllactose (2'FL), and 35% of lactose-N-neotetraose (...

Embodiment 2

[0056] A kind of infant formula milk powder of tooth protection, its raw material comprises following component by weight percentage:

[0057] Desalted cow whey powder 40%, whole milk powder (fresh milk dry matter is calculated as 12.0%) 25%, mixed vegetable oil 20%, concentrated whey protein powder 2.0%, glycomacropeptide 2.5%, lactose 6.66%, human milk low Polysaccharide 2.0%, DHA 0.2%, ARA 0.4%, Mixed Nucleotide 0.02%, Lactoferrin 0.025%, Taurine 0.025%, L-Carnitine 0.02%, Multivitamin Premix 0.25%, Multimineral 0.7% of premix, 0.2% of Lactobacillus rhamnosus LGG freeze-dried powder (the content of which is 1×1010 CFU / g).

[0058] The mixed edible vegetable oil is formed by mixing the following components and weight percentages: 40% sunflower oil, 30% coconut oil, 20% soybean oil, and 10% palm oil.

[0059] The human milk oligosaccharides are mixed with the following components and weight percentages: 65% of 2'-fucosyllactose (2'FL), and 35% of lactose-N-neotetraose (LNnT)...

Embodiment 3

[0074] A kind of infant formula milk powder of tooth protection, its raw material comprises the following components by weight percentage:

[0075] Desalted cow whey powder 45%, whole milk powder (fresh milk dry matter calculated as 12.0%) 22.5%, mixed vegetable oil 21%, concentrated whey protein powder 1.5%, glycomacropeptide 1.5%, lactose 4.66%, human milk low Polysaccharide 2.0%, DHA 0.2%, ARA 0.4%, Mixed Nucleotide 0.02%, Lactoferrin 0.025%, Taurine 0.025%, L-Carnitine 0.02%, Multivitamin Premix 0.25%, Multimineral 0.7% of premix, 0.2% of Lactobacillus rhamnosus LGG freeze-dried powder (the content of which is 1×1010 CFU / g).

[0076] The mixed edible vegetable oil is formed by mixing the following components and weight percentages: 40% sunflower oil, 30% coconut oil, 20% soybean oil, and 10% palm oil.

[0077] The human milk oligosaccharides are mixed with the following components and weight percentages: 65% of 2'-fucosyllactose (2'FL), and 35% of lactose-N-neotetraose (L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com