Preparation method of collagen polypeptide nanospheres grafted hydration titanium oxide adsorption material

A collagen polypeptide and adsorption material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of cumbersome and difficult preparation process, and achieve the effects of easy availability of raw materials, simple production process, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

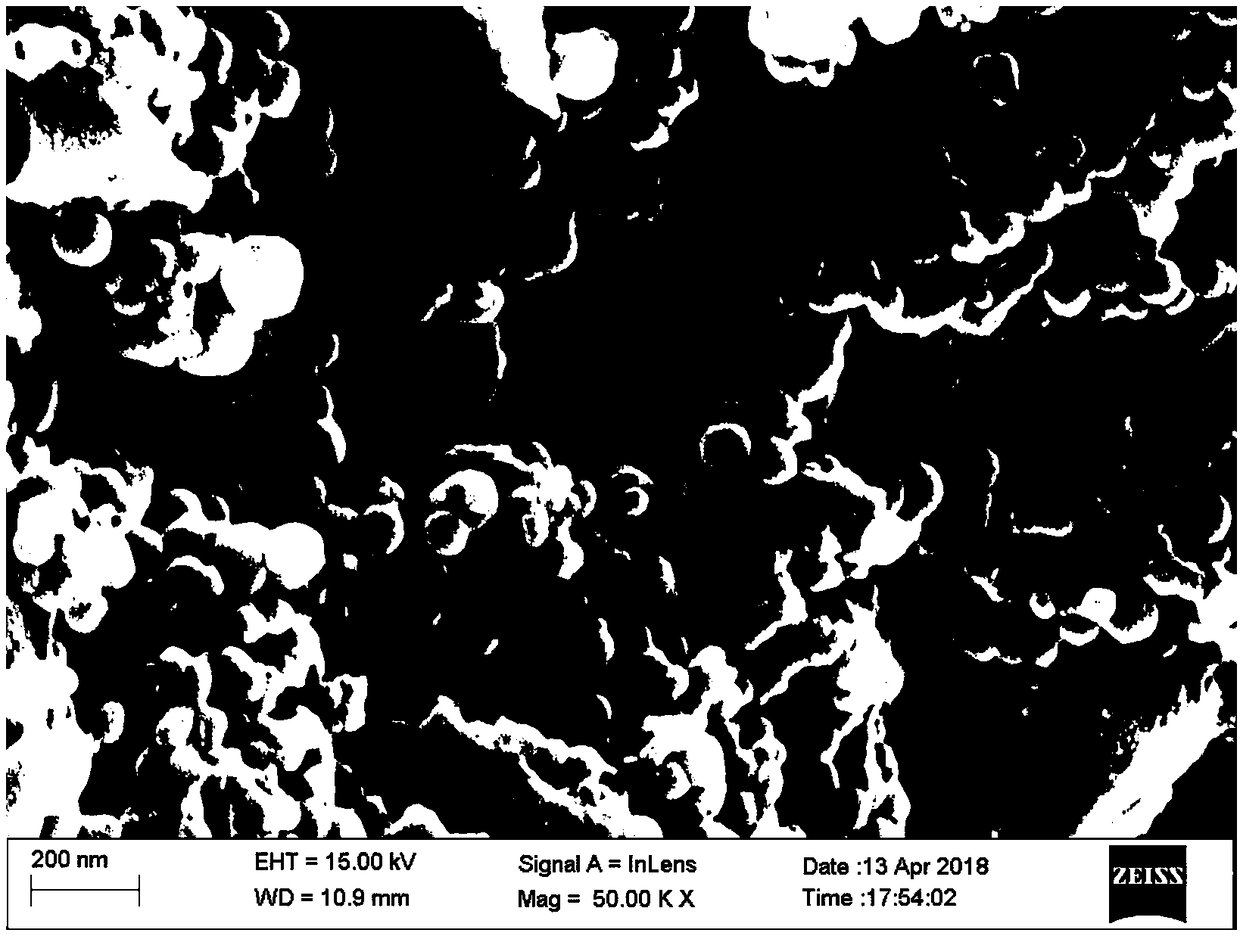

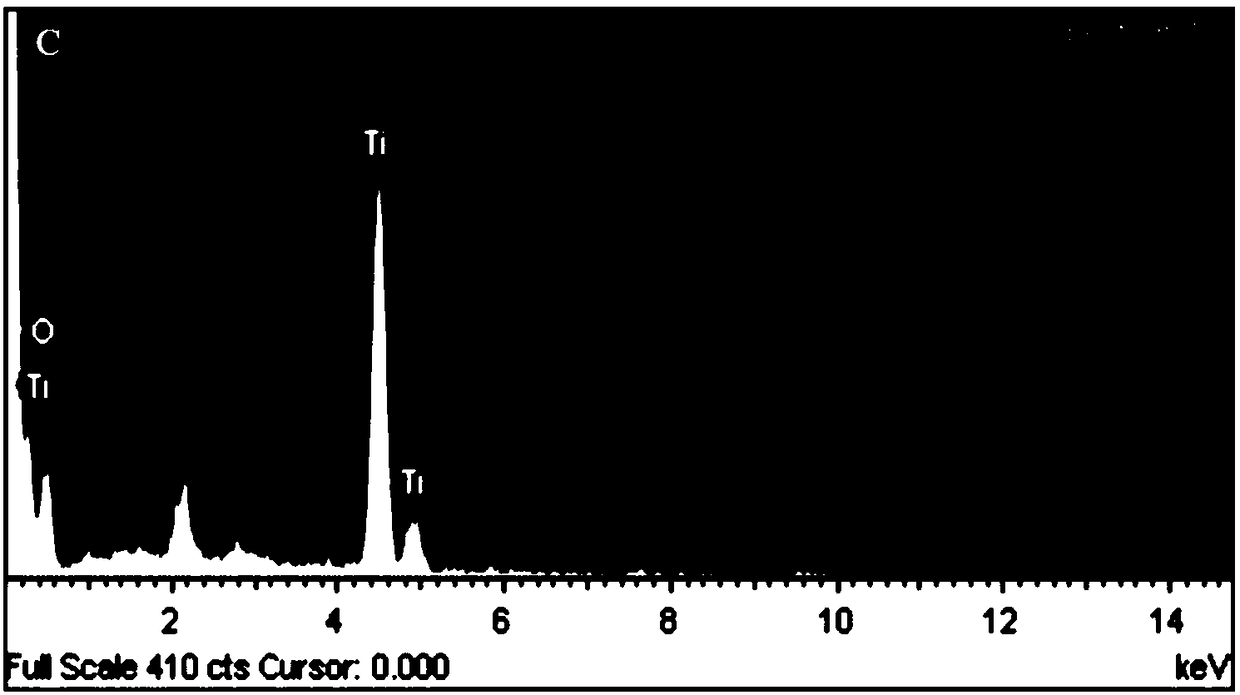

[0031] A preparation method of collagen polypeptide nanosphere grafted hydrated titanium oxide adsorption material, comprising the following steps:

[0032] Step 1, taking tanning waste collagen, pulverizing and hydrolyzing it to obtain hydrolyzed collagen polypeptide, taking the hydrolyzed collagen polypeptide and adopting a gel-sol method to obtain a suspension of collagen polypeptide nanospheres;

[0033] Step 2: Add the collagen polypeptide nanosphere suspension to the container, then add the masking agent formic acid and titanium sulfate solution, stir for 4 hours, and use Na 2 CO 3Adjust the pH to 3.5, seal the container, place it in a shaker, react at a temperature of 45°C for 4 hours, then let it stand at room temperature for 3 hours, centrifuge, discard the supernatant, and freeze the residue after washing Drying, the collagen polypeptide nanosphere grafted hydrated titanium oxide adsorption material is obtained; the mass ratio of the hydrolyzed collagen polypeptide ...

Embodiment 2

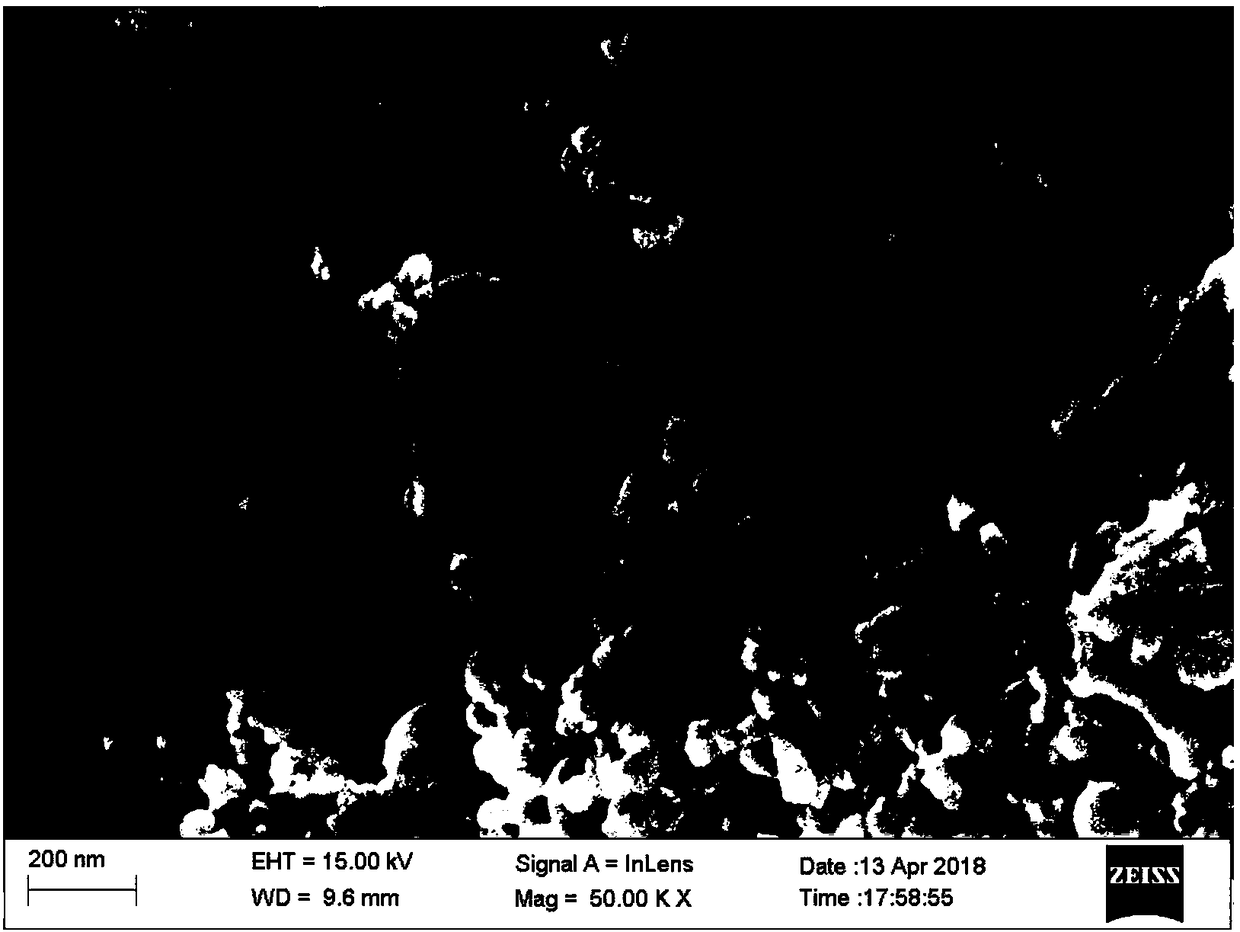

[0037] A preparation method of collagen polypeptide nanosphere grafted hydrated titanium oxide adsorption material, comprising the following steps:

[0038] Step 1, taking tanning waste collagen, pulverizing and hydrolyzing it to obtain hydrolyzed collagen polypeptide, taking the hydrolyzed collagen polypeptide and adopting a gel-sol method to obtain a suspension of collagen polypeptide nanospheres;

[0039] Step 2: Add the suspension of collagen polypeptide nanospheres to the container, then add the masking agent tartaric acid and titanium sulfate solution, stir for 5 hours, and use NaHCO 3 Adjust the pH to 3.5, seal the container, place it in a shaker, react at a temperature of 40°C for 3 hours, then let it stand at room temperature for 2 hours, centrifuge, discard the supernatant, and freeze the residue after washing Drying, the collagen polypeptide nanosphere grafted hydrated titanium oxide adsorption material is obtained; the mass ratio of the hydrolyzed collagen polypept...

Embodiment 3

[0042] A preparation method of collagen polypeptide nanosphere grafted hydrated titanium oxide adsorption material, comprising the following steps:

[0043] Step 1, taking tanning waste collagen, pulverizing and hydrolyzing it to obtain hydrolyzed collagen polypeptide, taking the hydrolyzed collagen polypeptide and adopting a gel-sol method to obtain a suspension of collagen polypeptide nanospheres;

[0044] Step 2: Add the suspension of collagen polypeptide nanospheres into the container, then add the masking agent oxalic acid and titanium sulfate solution, stir for 3 hours, adjust the pH to 3.5 with ammonia water, seal the container, place it in a shaker, and set it at a temperature of React at 42°C for 5 hours, then stand at room temperature for 5 hours, centrifuge, discard the supernatant, and freeze-dry the residue after washing to obtain the collagen polypeptide nanosphere grafted hydrated titanium oxide adsorption material; collagen polypeptide The mass ratio of the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com