Hollow porous cube nanometer nickel sulfide and preparing method thereof

A cubic, nickel sulfide technology, applied in nickel sulfide and other directions, can solve problems such as difficulty in finding a template synthesis method, and achieve the effects of stable and reliable performance, short reaction period and uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation step of hollow porous cube nickel sulfide is as follows:

[0028] (1) Preparation of Ni-Co PBA precursor, the preparation process is as follows:

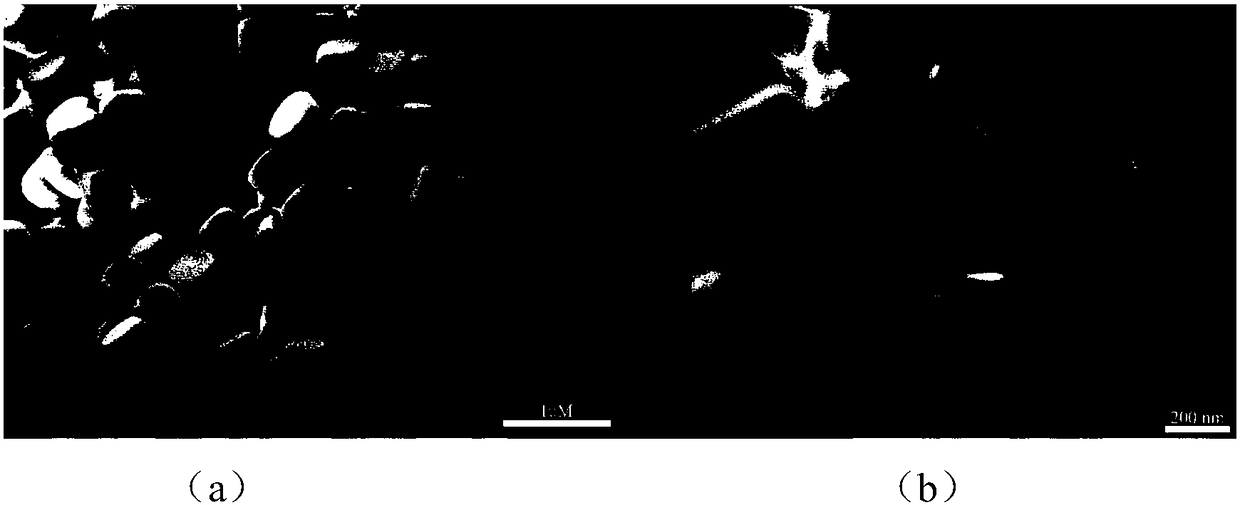

[0029] Weigh 3mmol of nickel nitrate hexahydrate and 4.5mmol of sodium citrate dihydrate and dissolve them in 100ml of deionized water to form liquid A; weigh 2mmol of potassium cobaltcyanide and dissolve them in 100ml of deionized water to form liquid B; mix liquids A and B Stir on a magnetic stirrer respectively; when the two solutions are clear, mix them together and stir for 3 minutes; after stirring evenly, let stand at room temperature for 24 hours; then carry out centrifugation (12000r / min) and ultrasonic washing respectively, after 3 After washing with alcohol and water, the samples were vacuum dried overnight at room temperature. Obtain a Ni-Co PBA precursor with uniform size and a size of about 400nm, see figure 1 shown.

[0030] (2) Preparation of NiS nanomaterials, the preparation process ...

Embodiment 2

[0033] (1) The preparation of Ni-Co PBA precursor is as embodiment 1

[0034] (2) Preparation of NiS nanomaterials, the preparation process is as follows:

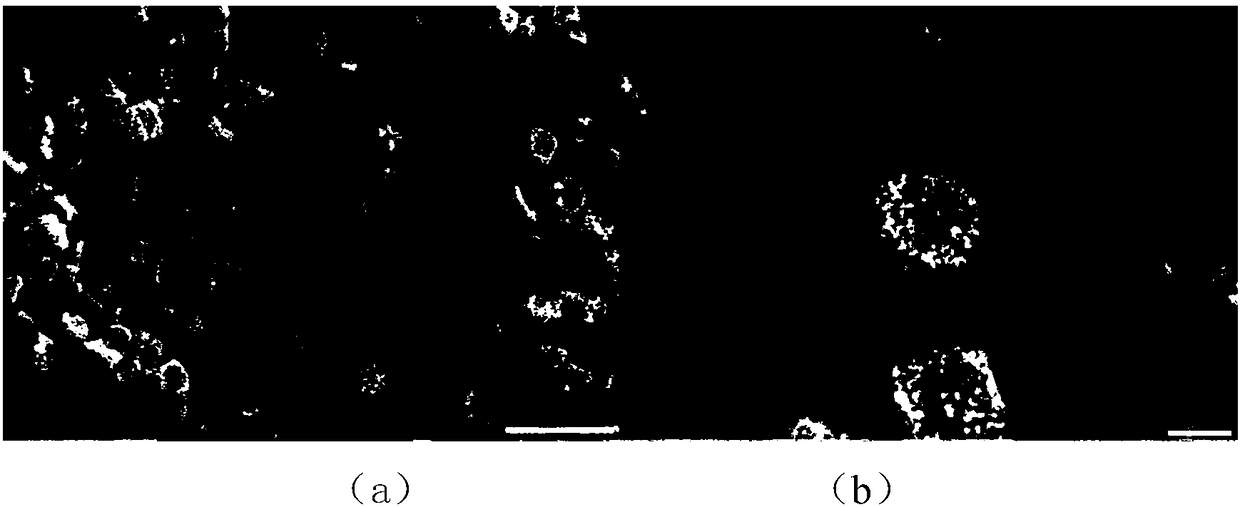

[0035] Weigh 40 mg of dried Ni-Co PBA precursor and dissolve it in 40 ml of absolute ethanol to form liquid A. At the same time, weigh 1 mmol of thioacetamide solid and 3 ml of aqueous sodium hydroxide solution (1M) in 17 ml of deionized Liquid B was formed in water, and after the two were ultrasonicated for 20 minutes, they were mixed and stirred on a magnetic stirrer for 5 minutes, then the mixed solution was transferred to a high-pressure reactor equipped with a polytetrafluoroethylene liner, and then placed in an oven at 100 °C, 120 °C, and 150 °C for 8 hours.

Embodiment 3

[0037] (1) The preparation of Ni-Co PBA precursor is as embodiment 1

[0038] (2) Preparation of NiS nanomaterials, the preparation process is as follows:

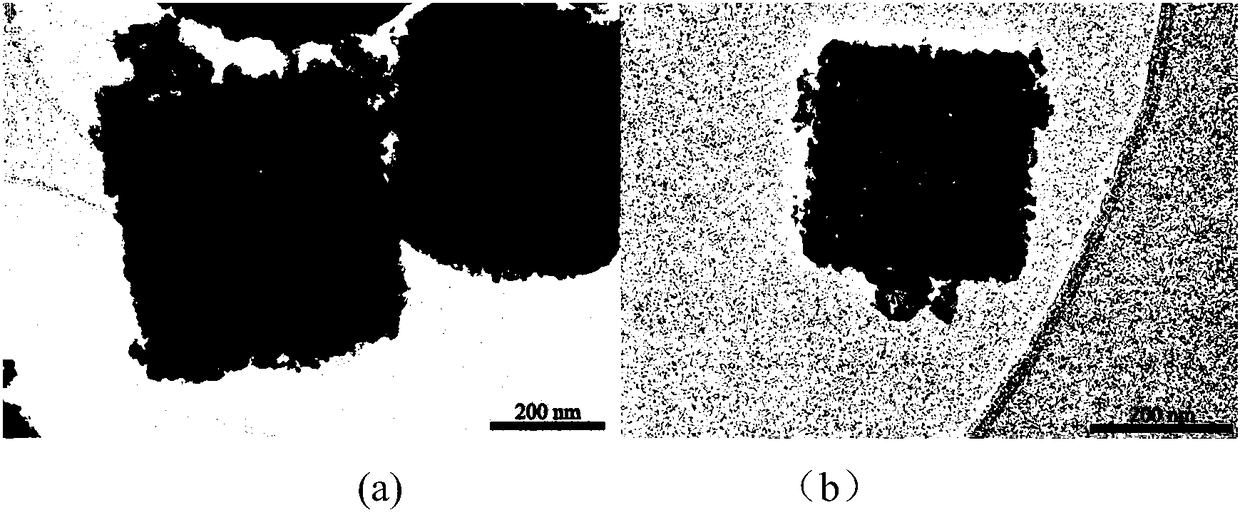

[0039] Weigh 40 mg of dried Ni-Co PBA precursor and dissolve it in absolute ethanol to form liquid A. At the same time, weigh 1 mmol of thioacetamide solid and 3 ml of aqueous sodium hydroxide solution (1M) and dissolve it in deionized water to form liquid B. Liquid, wherein the volume ratio of the alcohol solvent of liquid A and the water solvent of liquid B are V (alcohol): V (water) = 0:3, 1:2, 1:1, 2:1 respectively. After the two were sonicated for 20 minutes, they were mixed and stirred on a magnetic stirrer for 5 minutes, and then the mixture was transferred to a high-pressure reactor equipped with a polytetrafluoroethylene liner, and then placed in an oven at 100°C for 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com