Ammonium phosphate conditioner and preparation method and application thereof

A technology of conditioner and ammonium phosphate, which is applied in the field of ammonium phosphate conditioner and its preparation, can solve the problems of unfavorable fertilizer, synergistic fertilizer utilization rate, improvement of particle roundness and gloss, non-degradable dyeing agent, etc., and is suitable for large-scale production , Improve the roundness and gloss, and improve the appearance of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The present invention also provides a preparation method of the ammonium phosphate conditioning agent described in the above technical scheme, comprising the following steps:

[0058] a) Mix tartrazine, polyethylene glycol, humic acid, polymerized amino acid, phosphoric acid and water to obtain an ammonium phosphate conditioner.

[0059] The invention mixes tartrazine, polyethylene glycol, humic acid, polymerized amino acid, phosphoric acid and water to obtain the ammonium phosphate conditioner. In the present invention, the process of said mixing is preferably specifically:

[0060] Add phosphoric acid into water, then add tartrazine, after being completely dissolved, then add polyethylene glycol, humic acid and polymerized amino acid in sequence, stir until completely dissolved, and obtain the ammonium phosphate conditioner. The present invention has no special limitation on the stirring method, and the technical solution of mechanical stirring or manual stirring wel...

Embodiment 1

[0079] (1) Add 2kg of phosphoric acid to 79kg of water under stirring conditions, then add 6kg of tartrazine, after completely dissolving, add 8kg of polyethylene glycol 400, 2kg of potassium humate and 3kg of polyaspartic acid successively, at 25 Stir at ℃ for 30 minutes until the solution is completely dissolved to obtain ammonium phosphate conditioner.

[0080] (2) Add the ammonium phosphate conditioner obtained in step (1) to the slurry before monoammonium phosphate granulation in an amount of 1 kg / t and mix evenly to obtain an ammonium phosphate product with smooth particle surface and uniform dyeing.

[0081] The sample photo of the ammonium phosphate conditioner that the embodiment of the present invention 1 obtains is referring to figure 2 Shown; The dyeing effect figure of the ammonium phosphate product that the embodiment of the present invention 1 obtains is referring to image 3 shown.

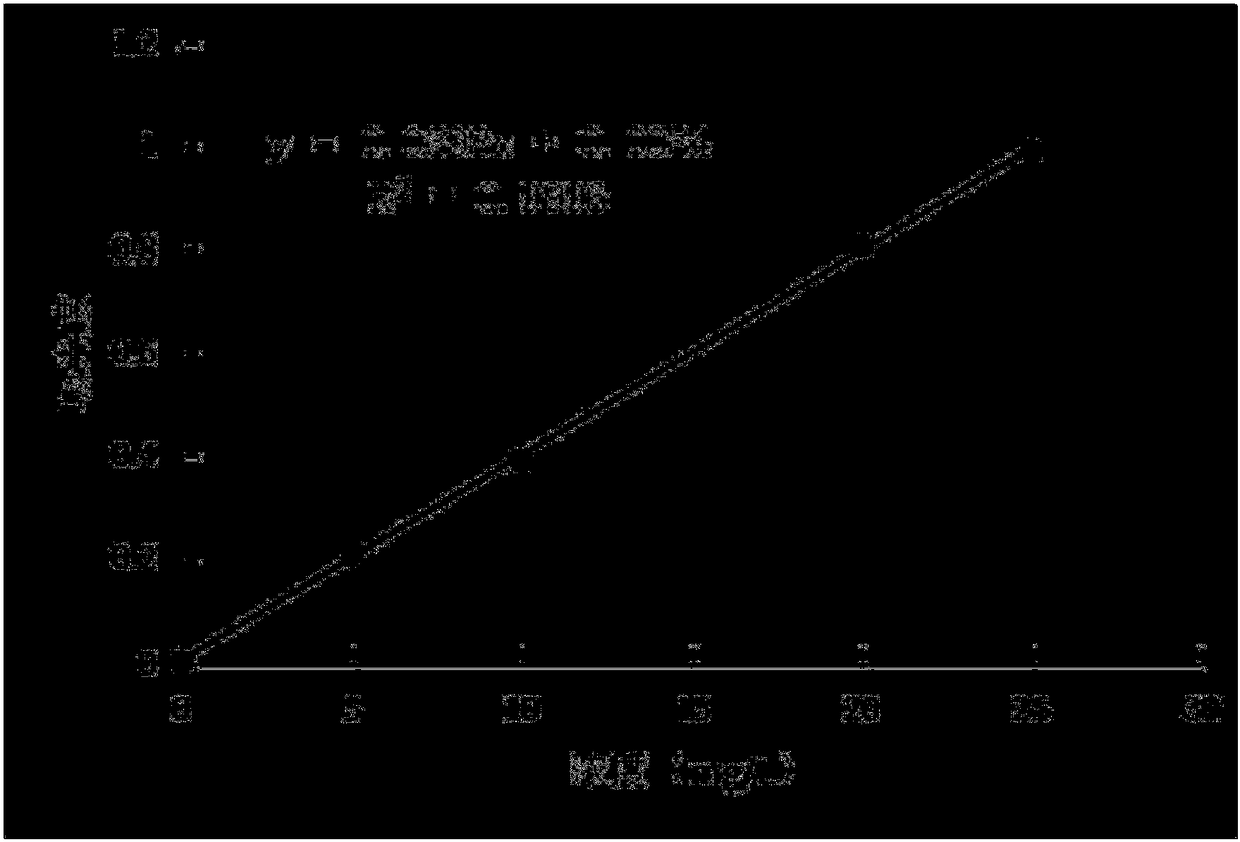

[0082] The ammonium phosphate product utilization rate (fertilizer effect) ...

Embodiment 2

[0090] (1) 5kg phosphoric acid is added in 77kg water under the condition of stirring, then add 7kg tartrazine, after treating to dissolve completely, then add 5kg polyethylene glycol 400, 5kg potassium fulvic acid and 1kg polyaspartic acid successively, in Stir at 25°C for 30 minutes until the solution is completely dissolved to obtain an ammonium phosphate conditioner.

[0091] (2) Add the ammonium phosphate conditioner obtained in step (1) to the slurry before diammonium phosphate granulation in an amount of 2 kg / t and mix evenly to obtain an ammonium phosphate product with smooth particle surface and uniform dyeing.

[0092] The dyeing effect figure of the ammonium phosphate product that the embodiment of the present invention 2 obtains is referring to Figure 4 shown.

[0093] According to the test method provided in Example 1, the utilization rate of the ammonium phosphate product provided in Example 2 of the present invention was tested, and compared with the unconditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com