Method for preparing metal soft magnetic powder through inorganic insulation coating

A metal soft magnetic, inorganic insulation technology, applied in the direction of inorganic material magnetism, magnetic materials, magnetic objects, etc., can solve the problems of continuous production, easy to agglomerate, etc., to improve production efficiency, high rust resistance, insulation high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing metal soft magnetic powder by inorganic insulating coating, comprising the following steps:

[0024] (1) Weigh sodium metaborate, sodium metaphosphate, nano-magnesium oxide, and nano-alumina respectively according to the proportioning ratio, and dissolve them in distilled water, and fully stir until an emulsion without precipitation at the bottom is obtained, that is, the coating agent is obtained;

[0025] (2) Weigh the iron-silicon-chromium alloy powder according to the proportion, and place it in the mixer, then add the coating agent therein, stir and mix to obtain the original slurry; preferably, the stirring throw in this step adopts double planetary The mixer is carried out, and the parameters are set as follows: the rotation speed is 40r / min, the temperature is 20-25°C, and the stirring time is 15-30min.

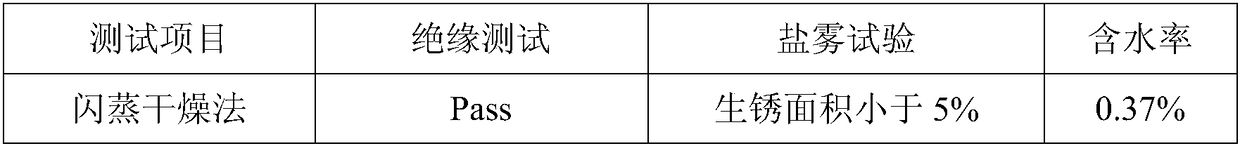

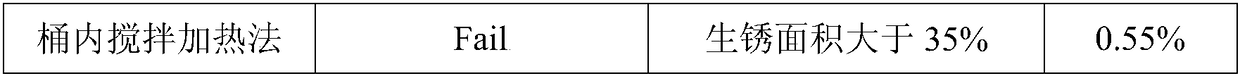

[0026] (3) The raw slurry is dried by a flash drying method to obtain a powdery product with uniform particles.

[0027] The dosages of...

Embodiment 2

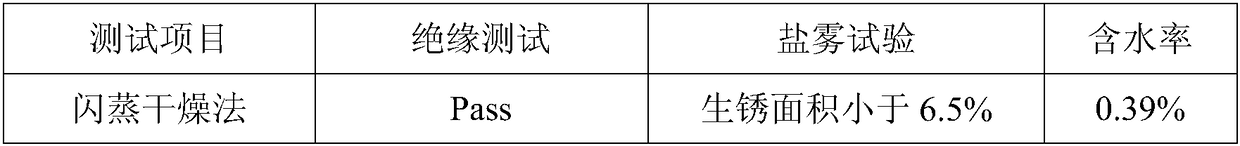

[0041] The difference between this embodiment and Embodiment 1 is that the soft magnetic metal powder is carbonyl iron powder, and the dosage and related parameters of other raw materials are the same as those in Embodiment 1.

Embodiment 3

[0049] The soft magnetic metal powder used in the present embodiment is iron silicon chromium alloy powder, and its difference with embodiment 1 is that the consumption of described sodium metaborate, sodium metaphosphate, nano magnesium oxide, nano aluminum oxide and distilled water is respectively 1.4%, 2.3%, 0.32%, 0.89%, 12% of the mass of soft magnetic powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com