Silica and zinc oxide anti-reflection film for dye-sensitized solar cells and preparation method

A solar cell and dye sensitization technology, which is applied in the field of anti-reflection film preparation for dye-sensitized solar cells, can solve the problems of reducing light transmittance, etc., and achieve the effect of increasing transmittance and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

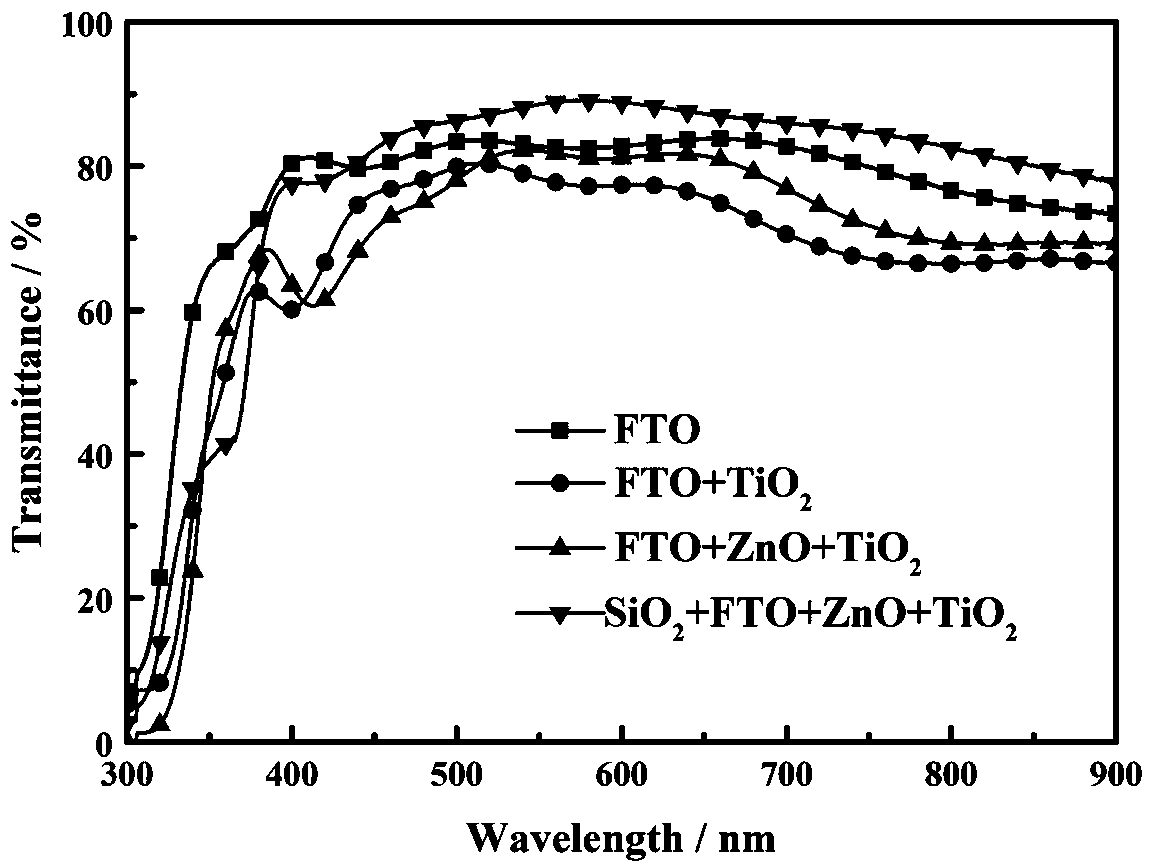

[0031] The preparation method of silicon dioxide and zinc oxide anti-reflection film for dye-sensitized solar cells comprises the following steps:

[0032] In step 1, zinc acetate is used as a zinc source, and triethanolamine is used as a catalyst to provide an alkaline environment and a stable pH value. Under ice-bath conditions, zinc acetate and triethanolamine were added to absolute ethanol, mixed uniformly and stirred for 15 minutes, heated to 45° C. and stirred for 1 hour to obtain ZnO sol. The ZnO sol was coated on the conductive surface of the FTO by the spin coating method, and then dried at 100°C for 10 min, and the anti-reflection ZnO film was obtained by repeating twice.

[0033] In step 2, butyl titanate is used as a titanium source and triethanolamine is used as a catalyst to provide an alkaline environment and a stable pH value. Under ice bath conditions, add butyl titanate and triethanolamine to absolute ethanol, mix well and stir at room temperature for 12 hou...

Embodiment 1

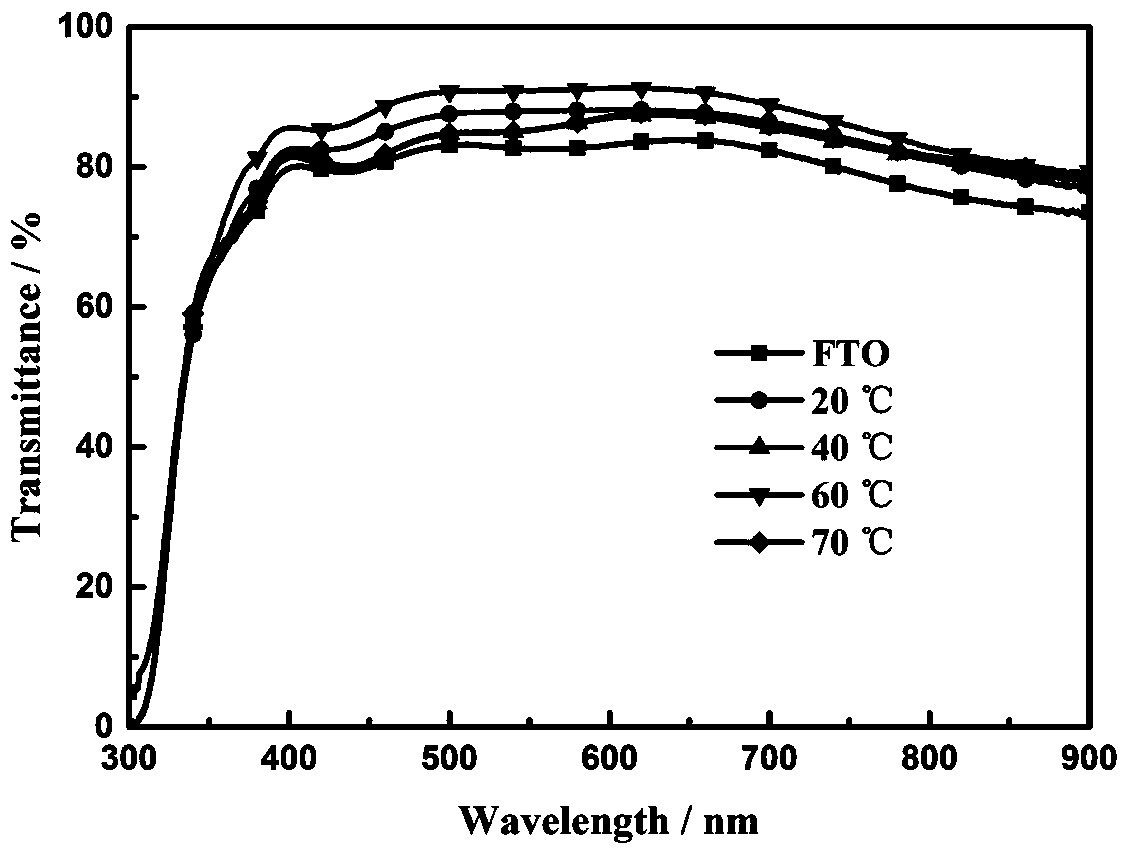

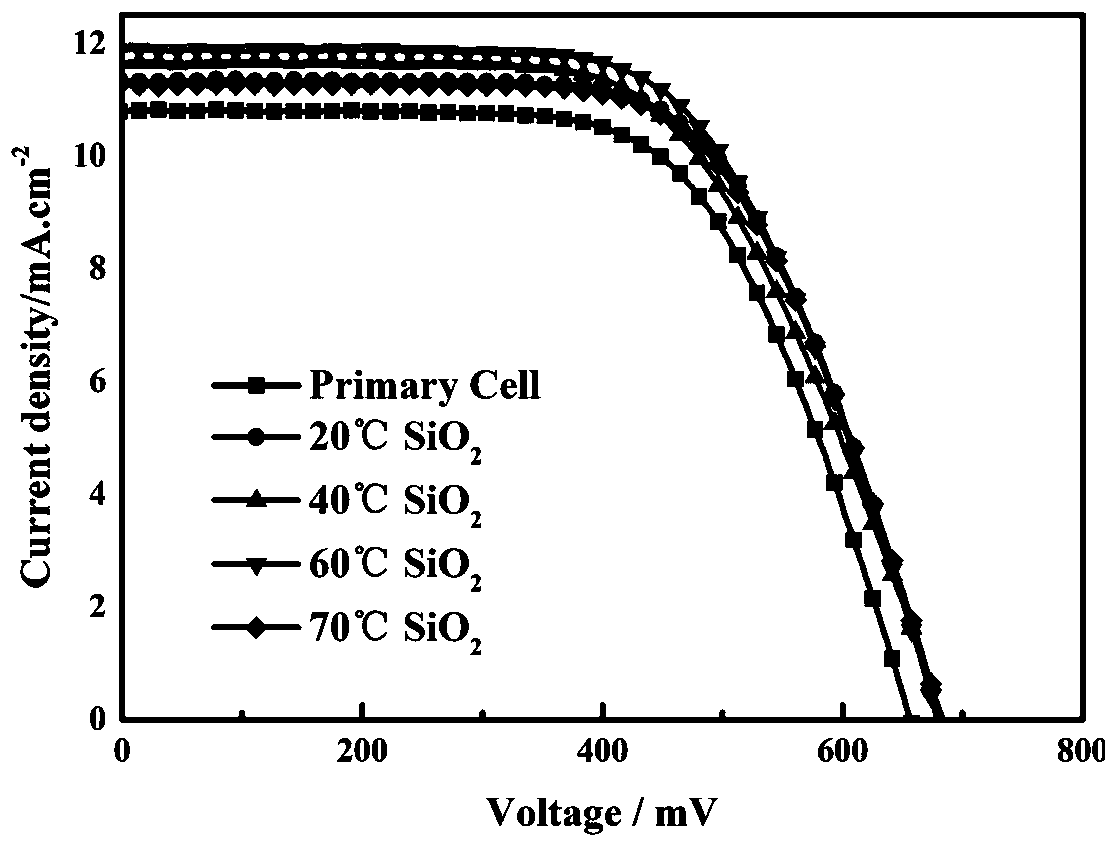

[0038] A SiO 2 Antireflection film is used for the preparation method of dye-sensitized solar cell, and its technological process is as follows:

[0039] In step 1, butyl titanate is used as a titanium source and triethanolamine is used as a catalyst to provide an alkaline environment and a stable pH value. Under ice bath conditions, add butyl titanate and triethanolamine to absolute ethanol, mix well and stir at room temperature for 12 hours to obtain TiO 2 Sol. TiO was coated by spin coating 2 The sol is coated on the surface of the ZnO film, and then calcined at 500 ° C for 30 min to obtain the ZnO anti-reflection layer and TiO 2 dense layer.

[0040] Step 2, using screen printing method on TiO 2 A layer of porous TiO with a thickness of 10 μm was printed on the dense layer 2 The electrode was sintered at 500°C for 30 minutes, and the N719 dye was adsorbed for 12 hours. The photoanode and the counter electrode were connected through a quasi-solid electrolyte to assemb...

Embodiment 2

[0044] A preparation method of ZnO anti-reflection film, its technical process is as follows:

[0045] Under the condition of ice bath, add zinc acetate and triethanolamine to absolute ethanol, mix uniformly and stir for 15min, the molar ratio of zinc acetate and triethanolamine is 1:1, heat to 45°C and stir for 1h to obtain ZnO sol. The ZnO sol was coated on the conductive surface of the FTO by the spin coating method, and then dried at 100°C for 10 min, and the anti-reflection ZnO film was obtained by repeating twice.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com