Porous three-dimensional graphene supercapacitor electrode material and preparation method thereof

A supercapacitor electrode, three-dimensional porous technology, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc. Problems such as low material utilization rate, to achieve the effect of improving electrical conductivity, reducing process time, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

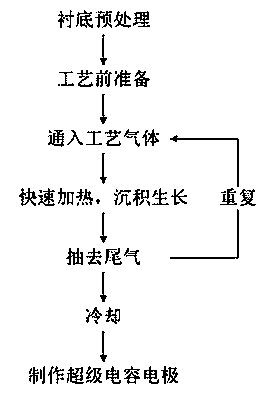

[0031] The present embodiment provides a kind of preparation method of three-dimensional porous graphene supercapacitor electrode material, the flow process of this method is as follows figure 1 As shown, the specific steps are as follows:

[0032] Step 1, the commercial three-dimensional nickel foam is washed with deionized water and ethanol in turn as a substrate, placed in a CVD device, and the process chamber is vacuumed and purged with argon;

[0033] Step 2, pumping out the residual gas to a pressure within 10Pa;

[0034] Step 3, feed hydrogen and methane, the flow rate of hydrogen is 100 sccm, the flow rate of methane is 50 sccm, and the pressure of the cavity is controlled at 5000 Pa;

[0035] Step 4, heating the three-dimensional nickel foam substrate by induction heating, the heating temperature is 1000°C, and starting to deposit and grow three-dimensional porous graphene, and the deposition reaction time is 20 seconds;

[0036] Step five, repeat steps two to four,...

Embodiment 2

[0040] The present embodiment provides a kind of preparation method of three-dimensional porous graphene supercapacitor electrode material, the flow process of this method is as follows figure 1 As shown, the specific steps are as follows:

[0041] Step 1, the commercial three-dimensional copper foam is washed with deionized water and ethanol in turn as a substrate, placed in a CVD device, and the process chamber is vacuumed and purged with argon;

[0042] Step 2, pumping out the residual gas to a pressure within 10Pa;

[0043] Step 3, feed hydrogen and ethylene, the flow rate of hydrogen is 50 sccm, the flow rate of ethylene is 10 sccm, and the pressure of the chamber is controlled at 1000 Pa;

[0044] In step four, the three-dimensional copper foam substrate is heated by induction heating, and the heating temperature is 1050°C. Start to deposit and grow three-dimensional porous graphene, and the deposition reaction time is 5 minutes;

[0045] Step 5, repeat steps 2 to 4, ...

Embodiment 3

[0049] This embodiment is to investigate the influence of process pressure on the specific capacitance performance of the prepared three-dimensional porous graphene supercapacitor electrode material. Other conditions are the same as in Example 1, except that the cavity pressure is controlled at 1000Pa. The electrochemical performance test of the three-dimensional porous graphene supercapacitor electrode material of Example 3 in a 5M KOH electrolyte was carried out using an electrochemical workstation. The test results show that when the charge and discharge current density is 1A / g, the specific capacitance of the electrode is 116F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com