Recycling method of positive plates for lithium ion batteries

A technology of lithium ion battery and positive electrode sheet is applied in the field of recycling and utilization of lithium ion battery, which can solve the problem of low removal efficiency of positive electrode material, and achieve the effect of efficient recycling and high removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

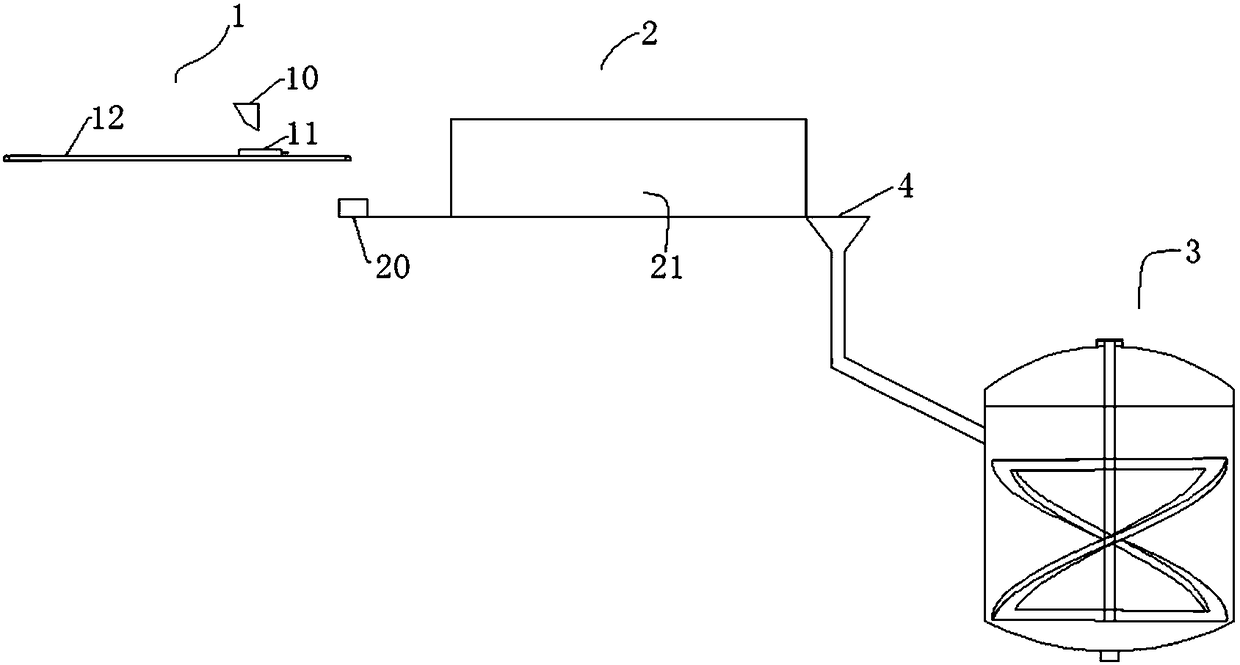

Image

Examples

Embodiment 1

[0023] The recycling method of the lithium-ion battery positive plate of the present embodiment adopts the following steps:

[0024] 1) Cut the scrapped positive electrode sheets on the production line into small pieces with a diameter of 1 cm, and then heat-treat them at 300°C for 3 hours, and then put them into a vibrating sieve with a mesh diameter of 1 mm. Pre-separation of fluid, the undersize is ternary material powder, and the oversize is pre-separated pole pieces;

[0025] 2) Place the pre-separated pole piece in an ultrasonic stirring device, then add NMP solvent, and process the pre-separated pole piece under stirring and ultrasonic assistance. The stirring speed is 100r / min, the frequency of ultrasonic treatment is 30KHz, and the time is 2h, carry out coarse filtration to the treated mixed solution, and separate the aluminum foil and the positive electrode material slurry;

[0026] 3) Dry the cathode material slurry in an oven at 110° C. to recover the ternary mate...

Embodiment 2

[0028] The recycling method of the lithium-ion battery positive plate of the present embodiment adopts the following steps:

[0029] 1) Cut the positive electrode sheet obtained after dismantling the lithium-ion battery into small pieces with a diameter of 1cm, and then heat-treat it at 250°C for 4h, and then put it into a vibrating sieve with a mesh diameter of 1mm. Pre-separation of materials and current collectors, the undersize is ternary material powder, and the oversize is pre-separated pole pieces;

[0030] 2) Place the pre-separated pole piece in an ultrasonic stirring device, then add NMP solvent, and process the pre-separated pole piece under stirring and ultrasonic assistance. The stirring speed is 120r / min, the frequency of ultrasonic treatment is 30KHz, and the time is 3h, coarsely filter the treated mixed solution, and separate the aluminum foil and positive electrode material slurry;

[0031] 3) Dry the cathode material slurry in an oven at 100°C to recover the...

Embodiment 3

[0033] The recycling method of the lithium-ion battery positive plate of the present embodiment adopts the following steps:

[0034] 1) Cut the positive electrode sheet obtained after dismantling the lithium-ion battery into small pieces with a diameter of 1cm, and then heat-treat it at 400°C for 2h, then put it into a vibrating sieve with a mesh diameter of 1mm, and vibrate and sieve to achieve ternary Pre-separation of materials and current collectors, the undersize is ternary material powder, and the oversize is pre-separated pole pieces;

[0035] 2) Place the pre-separated pole piece in an ultrasonic stirring device, then add acetone, and process the pre-separated pole piece under stirring and ultrasonic assistance. The stirring speed is 150r / min, the frequency of ultrasonic treatment is 25KHz, and the time is 4h , coarsely filtering the treated mixed solution to separate the aluminum foil and positive electrode material slurry;

[0036] 3) Dry the cathode material slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com