Preparation method of selenium-rich and zinc-rich protein peptide

A protein peptide and zinc-rich technology, applied in the field of preparation of selenium-rich zinc-rich protein peptide, can solve the problems of low selenium and zinc content, low extraction efficiency, complex process, etc., to enhance physiological functions, reduce residual content, and enhance physiological functions. The effect of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

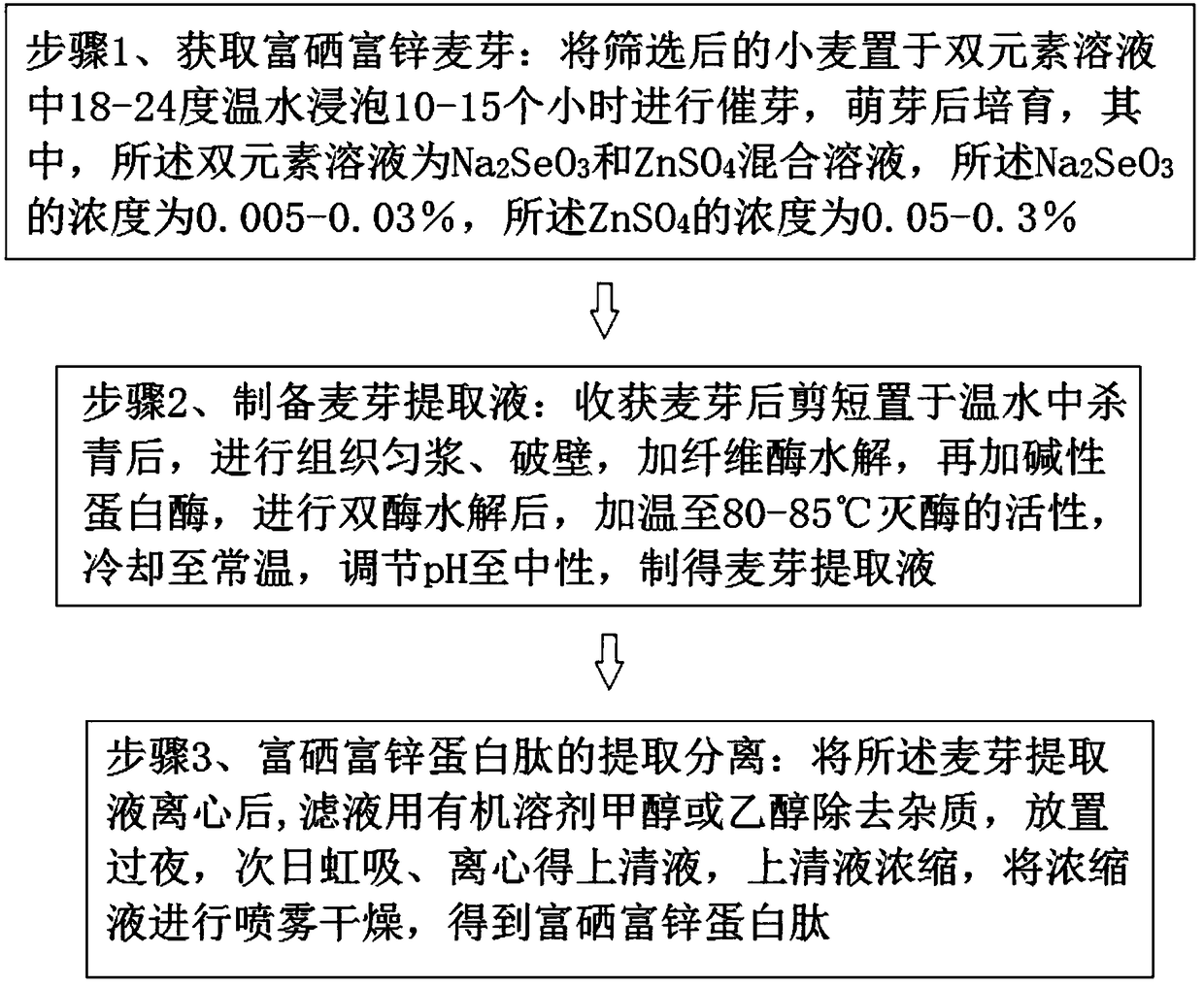

Method used

Image

Examples

Embodiment 1

[0014] Example 1 Preparation of selenium-rich zinc-rich protein peptide

[0015] 1. Prepare experimental materials

[0016] A. Using locally grown Chumai 0805 as the main experimental material;

[0017] B. Exogenous protease: Cellulase, acid protease (200,000 U / g), neutral protease (200,000 U / g), alkaline protease (200,000 U / g) were purchased from Rovism (China) Biology Technology Co., Ltd.

[0018] 2. Experimental method

[0019] (1) Cultivation of selenium-enriched zinc-enriched malt: use Na-containing 2 SeO 3 200ppm and ZnSO 4 It is a two-element culture solution of 2000ppm, placed in a light incubator, the temperature is controlled at 18°C, and an appropriate humidity is maintained, and cultivated for 5 days. Among them, the ppm concentration (parts per million) is the concentration expressed by the solute mass in parts per million of the total solution mass, also known as the parts per million concentration. Often used in very small concentrations.

[0020] (2) Ho...

Embodiment 2

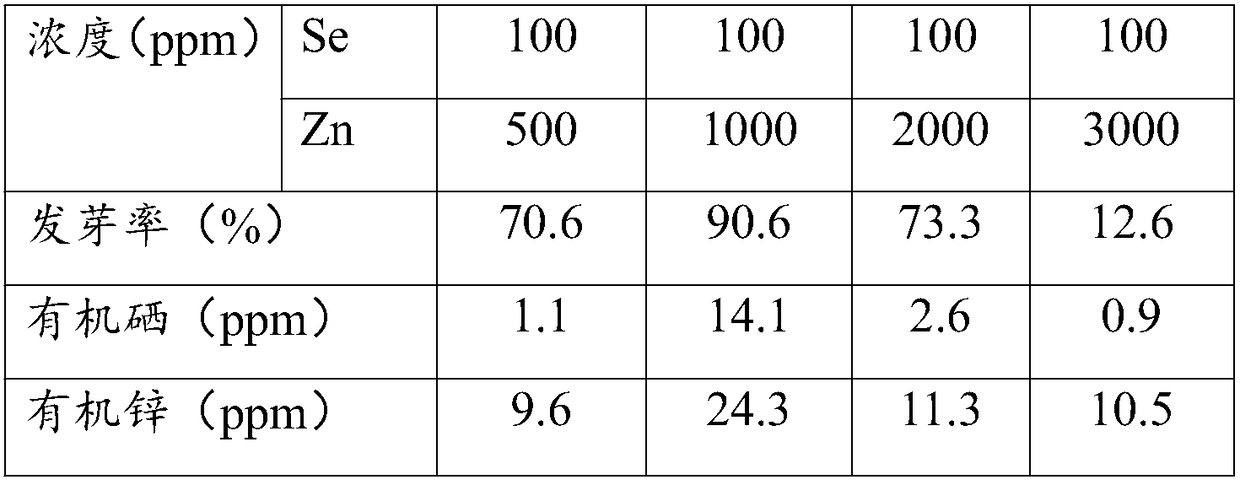

[0024] Na in embodiment 2 double element solution 2 SeO 3 with ZnSO 4 Exploration of matching ratio

[0025] Experimental group 1: with Na 2 SeO 3 100ppm and ZnSO 4 500ppm two-element culture solution;

[0026] Experimental group 2: with Na 2 SeO 3 100ppm and ZnSO 4 1000ppm two-element culture solution;

[0027] Experimental group 3: with Na 2 SeO 3 100ppm and ZnSO 4 2000ppm two-element culture solution;

[0028] Experimental group 4: with Na 2 SeO 3 100ppm and ZnSO 4 3000ppm two-element culture solution;

[0029] Four groups of wheat were cultivated for comparative experiments, placed in a light incubator, the temperature was controlled at 18°C, and the humidity was maintained for 5 days. The relative germination rate of wheat and the content of organic selenium and zinc were observed and determined, as shown in Table 1. It can be seen from the table that the optimal ratio is Na 2 SeO 3 Concentration is 100ppm, ZnSO 4 The concentration is 1000ppm, the germ...

Embodiment 3

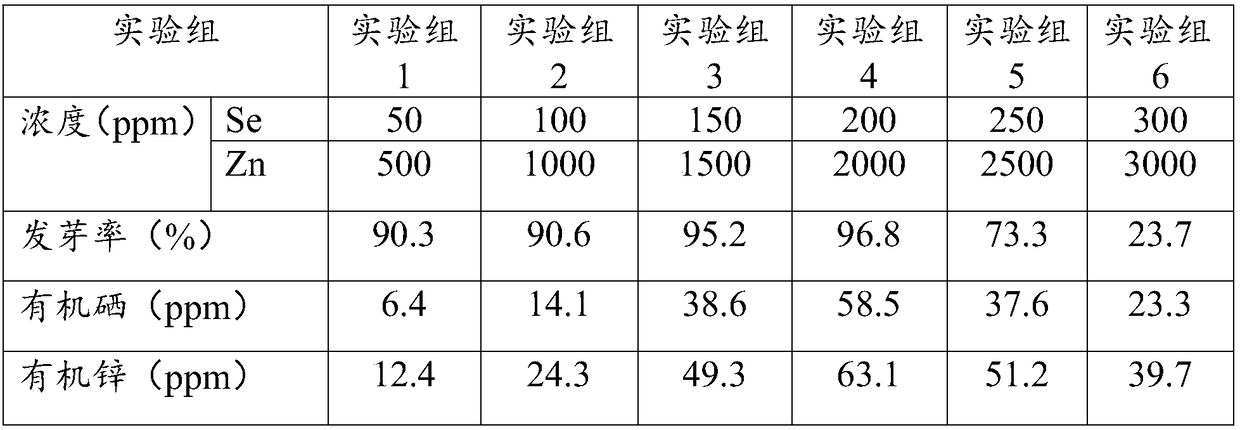

[0032] Na in embodiment 3 double element solution 2 SeO 3 with ZnSO 4 Concentration exploration and verification of cultivated malt rich in organic selenium and organic zinc

[0033] 1. Cultivation of selenium-enriched zinc-enriched malt: use Na 2 SeO 3 50ppm, 100ppm, 150ppm, 200ppm, 250ppm, 300ppm and one-to-one corresponding ZnSO 4 500ppm, 1000ppm, 1500ppm, 2000ppm, 2500ppm, and 3000ppm were configured into 6 kinds of two-element culture solutions with different concentrations, and they were used as experimental groups 1-6 respectively. These 6 groups of wheat were cultivated for comparative experiments, and placed in a light incubator with temperature control. At 18°C, maintain proper humidity, cultivate for 5 days, observe and measure the relative germination rate of wheat and the content of organic selenium and zinc, as shown in Table 2 below. And Na 2 SeO 3 Concentration greater than 200ppm and ZnSO 4 When it is greater than 2000ppm, the inhibitory effect on whea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com