Foam foaming agent for cement and preparation method of foam foaming agent

A foaming agent and foam technology, applied in the field of foam foaming agent for cement and its preparation, can solve the problems of poor performance and instability of cement foaming agent, and achieve the effects of fine slurry, smooth surface and long-lasting foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

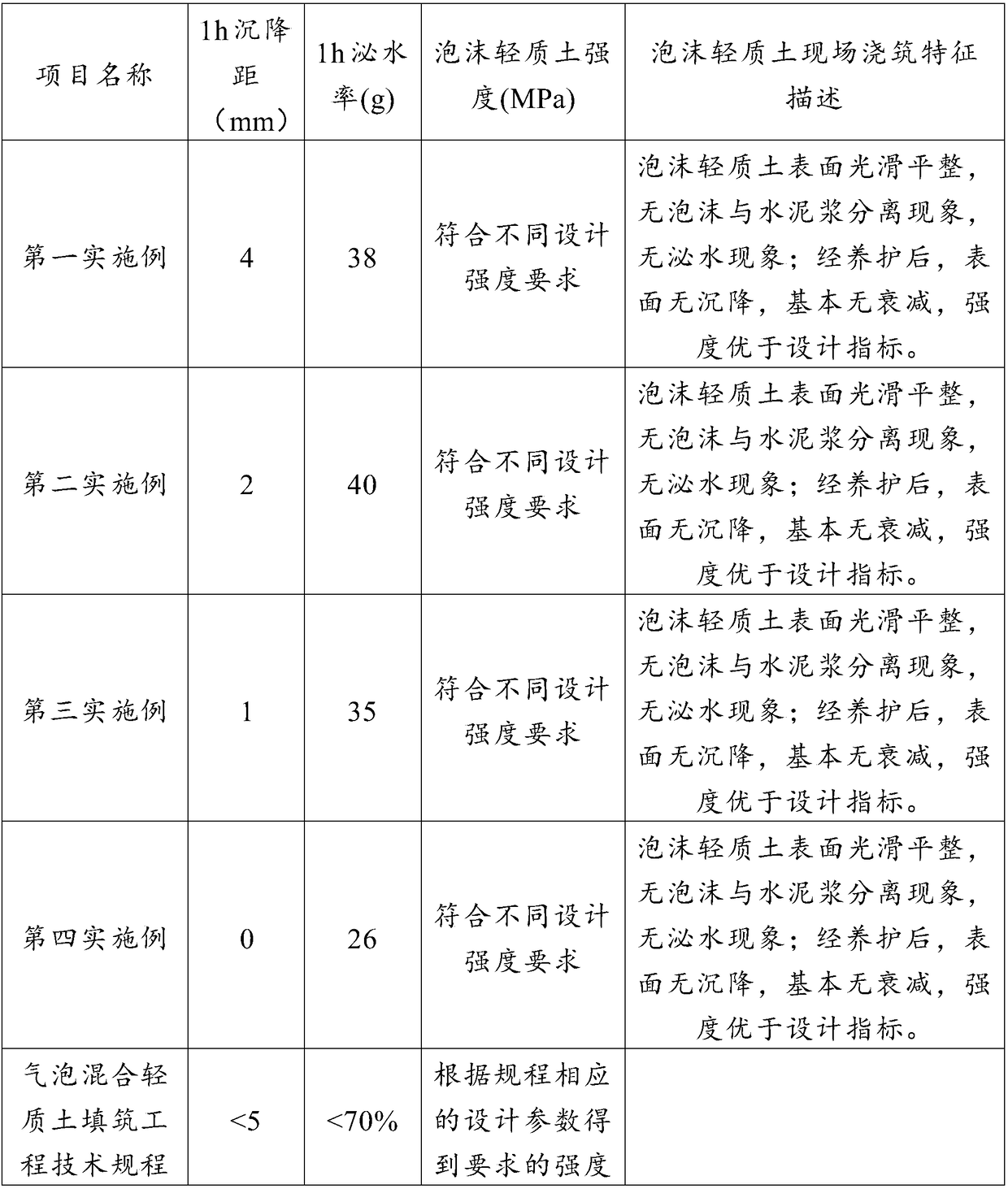

Examples

no. 1 example

[0020] The invention provides a foam foaming agent for cement, which comprises a main foaming material, a surfactant, a foam stabilizer, a chelating agent, an organic solvent and water.

[0021] Specifically, the main foaming material is sodium lauryl sulfate (K12).

[0022] The surfactant is selected from one or more of alpha-olefin sulfonate sodium (AOS), sodium lauryl polyoxyethylene ether sulfate (AES) or lauramide propylamine oxide (LAO-30).

[0023] In this embodiment, the surfactants include two anionic surfactants, sodium α-olefin sulfonate and sodium lauryl polyoxyethylene ether sulfate.

[0024] The foam stabilizer is silicone polyether (MPS).

[0025] The chelating agent is sodium citrate.

[0026] The organic solvent is ethylene glycol butyl ether.

[0027] The foam blowing agent for cement includes the following raw materials in weight percentage: sodium lauryl sulfate 4% to 5%, sodium α-olefin sulfonate 3.5% to 4.5%, sodium lauryl alcohol polyoxyethylene ether...

no. 2 example

[0054] The invention provides a foam foaming agent for cement, which comprises a main foaming material, a surfactant, a foam stabilizer, a chelating agent, an organic solvent and water.

[0055] Specifically, the main foaming material is sodium lauryl sulfate (K12).

[0056] The surfactant is selected from one or more of alpha-olefin sulfonate sodium (AOS), sodium lauryl polyoxyethylene ether sulfate (AES) or lauramide propylamine oxide (LAO-30).

[0057] In this embodiment, the anionic surfactant α-olefin sulfonate sodium (AOS) and the amphoteric surfactant lauramide propylamine oxide (LAO-30) are selected as surfactants.

[0058] The foam stabilizer is silicone polyether (MPS).

[0059] The chelating agent is sodium citrate.

[0060] The organic solvent is ethylene glycol butyl ether.

[0061] The foam blowing agent for cement of the present invention comprises the following raw materials in weight percentage: 4% to 5% of sodium lauryl sulfate, 3.5% to 4.5% of sodium α-ol...

no. 3 example

[0088] The invention provides a foam foaming agent for cement, which comprises a main foaming material, a surfactant, a foam stabilizer, a chelating agent, a thickener, an organic solvent and water.

[0089] Specifically, the main foaming material is sodium lauryl sulfate (K12).

[0090] The surfactant is selected from one or more of alpha-olefin sulfonate sodium (AOS), sodium lauryl polyoxyethylene ether sulfate (AES) or lauramide propylamine oxide (LAO-30).

[0091] In this embodiment, sodium lauryl polyoxyethylene ether sulfate (AES) is selected as the surfactant.

[0092] The foam stabilizer is silicone polyether (MPS).

[0093] The chelating agent is sodium citrate.

[0094] The organic solvent is ethylene glycol butyl ether.

[0095] The thickener is gum arabic.

[0096] The foam blowing agent for cement of the present invention comprises the following raw materials in weight percent: 4% to 5% of sodium lauryl sulfate, 9% to 10% of sodium lauryl alcohol polyoxyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bleeding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com