High syndiotactic vertical structure functionalized polystyrene polymer and preparation method thereof

A polystyrene and styrene-based technology, which is applied in the field of high syndiotactic functionalized polystyrene polymers and their preparation, can solve the problems of degradation, difficult control of functional group distribution, and local polymer chain structure damage. , to achieve the effect of high syndiotactic selective homopolymerization and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] A preparation method for highly syndiotactic functionalized polystyrene polymer, comprising the following steps:

[0071] The functionalized styrene is homopolymerized under the action of the catalyst, or the styrene and the functionalized styrene are copolymerized under the action of the catalyst to prepare a high syndiotactic functionalized polystyrene polymer.

[0072] The present invention uses rare earth complexes, organoboron compounds and organoaluminum compounds as catalysts to synthesize high syndiotactic copolymers of styrene and functionalized styrene by means of coordination polymerization, and the functionalized styrene structural units are in the polymer The insertion rate of the polymer can be adjusted arbitrarily, breaking through the previous limitation of low insertion rate of functionalized monomers in polymers, and the insertion rate can be as high as 100%. Due to the carbon-carbon double bond or carbon-carbon triple bond in the polymer, the subseque...

Embodiment 1

[0133] Take 5mL of Catalyst 1 solution, put it in a polymerization bottle that has been treated with anhydrous and oxygen free, add 5.0mmol functionalized styrene monomer A and 5.0mmol styrene monomer, carry out polymerization reaction at 25°C for 1 hour, then add 2mL ethanol solution of hydrochloric acid with a volume concentration of 10% terminates the polymerization reaction, pours the reaction solution into 100mL ethanol for sedimentation, and obtains a copolymer of styrene and functionalized styrene; then puts the obtained polymer in a vacuum drying oven at 40°C Drying at low temperature for 48 hours to obtain a dry constant weight copolymer of styrene and functionalized styrene with a total conversion rate of 100%.

[0134] H NMR spectroscopy ( 1 H NMR) and carbon nuclear magnetic resonance ( 13 C NMR) analyzes the copolymer of styrene and the functionalized styrene that obtains, and the result shows that its syndiotacticity is greater than 99%; The intercalation rate o...

Embodiment 2~51

[0136] According to the method described in Example 1, using the raw material ratio and reaction conditions in Table 2, the copolymers of styrene and functionalized styrene, or the homopolymer of functionalized styrene were prepared respectively; Table 2 is the present invention The raw material ratio, reaction conditions, and performance test results of Examples 2-51 are summarized.

[0137] Table 2 Raw material ratio, reaction conditions, and performance test results summary of Examples 2-51 of the present invention

[0138]

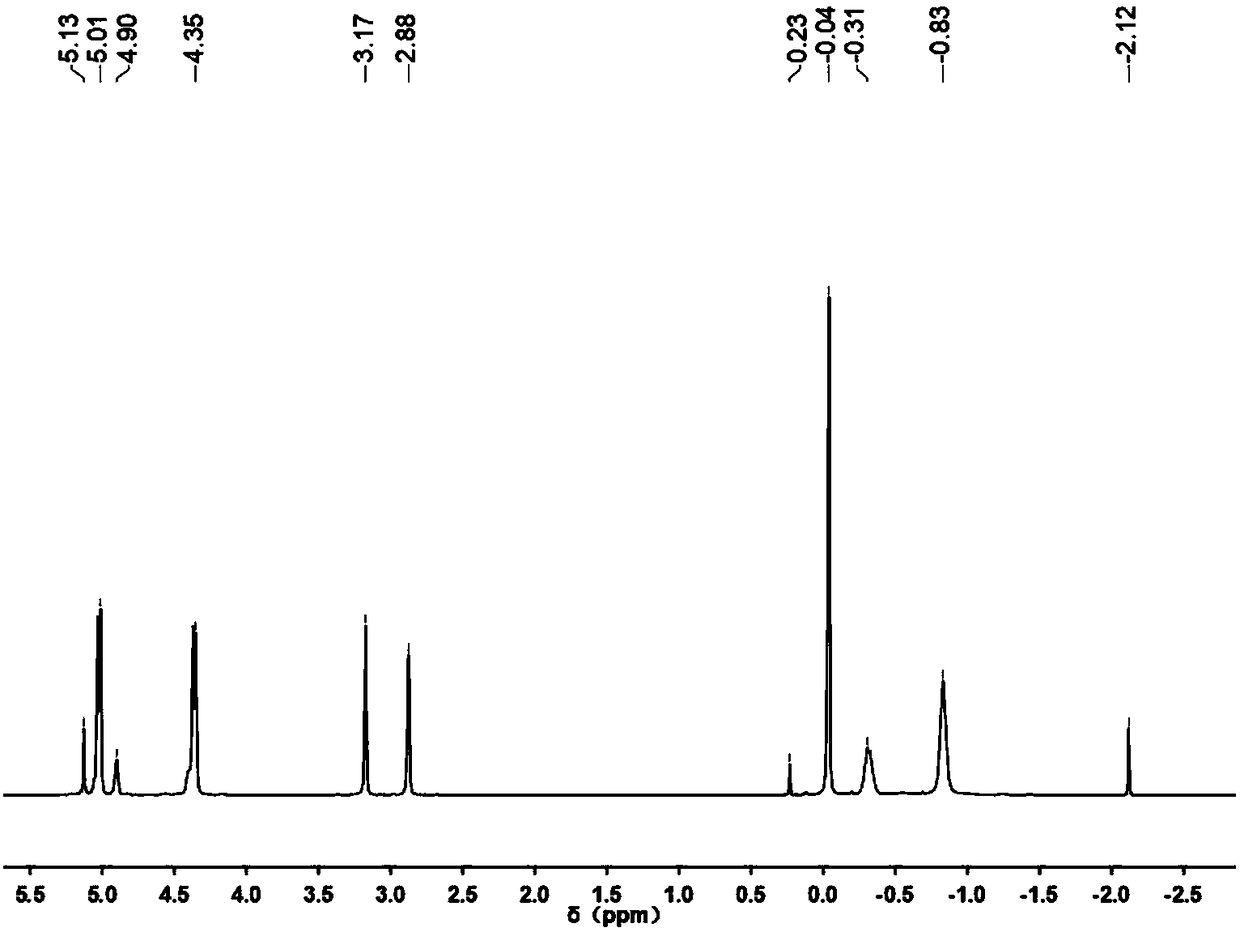

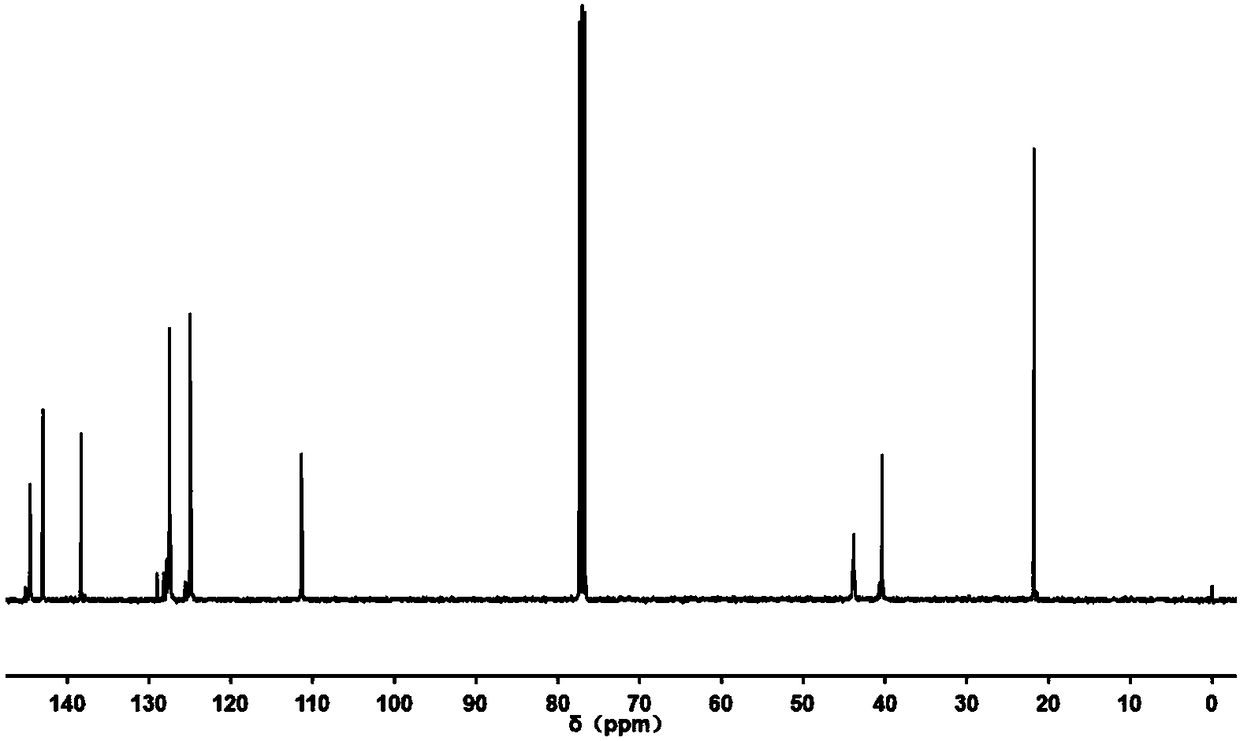

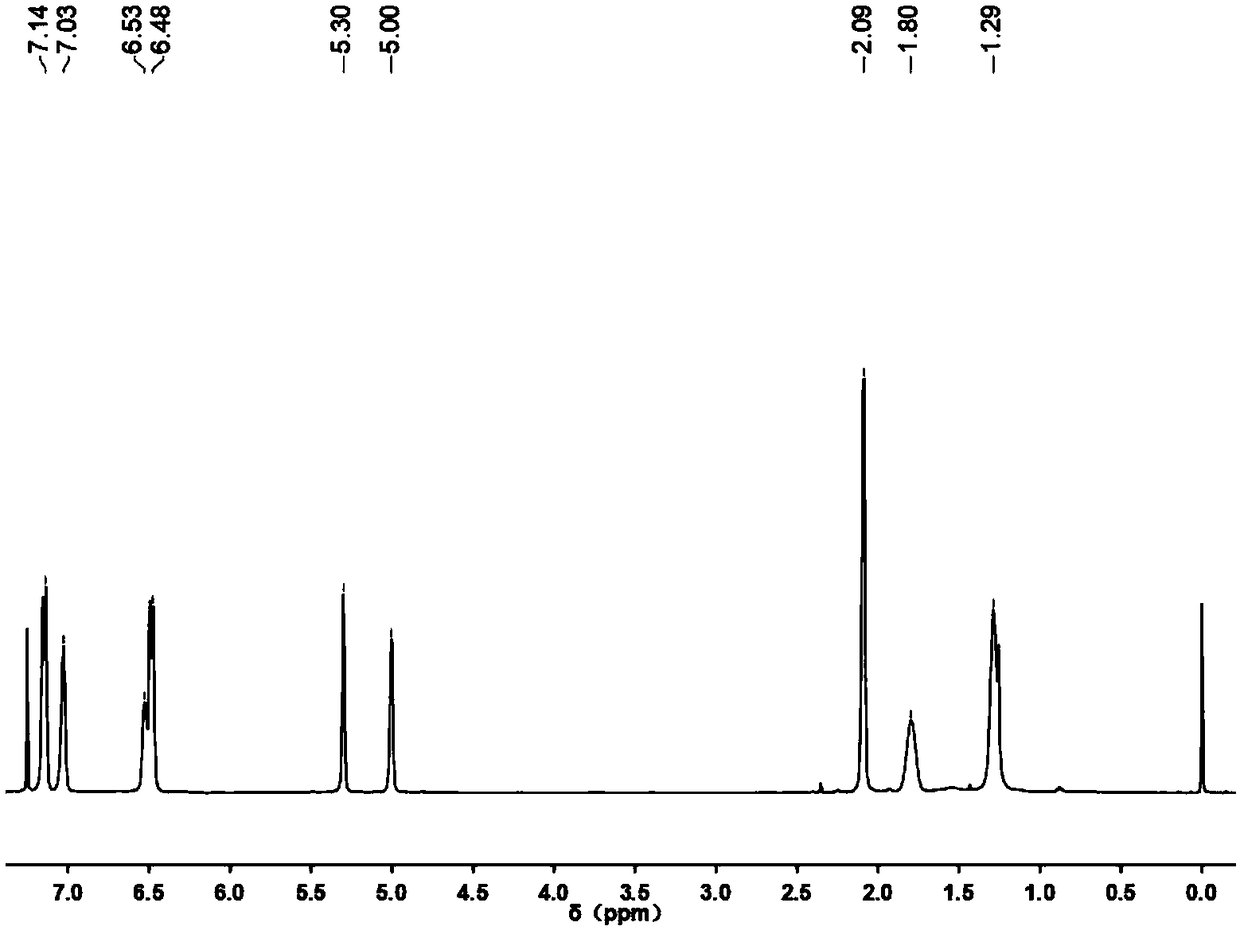

[0139] The copolymers of styrene and p-isopropenylstyrene prepared in Example 9 of the present invention were detected by proton nuclear magnetic resonance spectrum and carbon spectrum, and the detection results are shown in figure 1 with figure 2 ,in figure 1 It is the H NMR spectrum of the copolymer of styrene and p-isopropenylstyrene prepared in Example 9 of the present invention, figure 2 It is the carbon nuclear magnetic resonance spectrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com