A kind of pvdc water-based emulsion for coating

A water-based emulsion and coating technology, which is applied in coatings, latex paints, fireproof coatings, etc., can solve the problems of low impact strength, poor thermal stability and anti-yellowing ability, and the barrier performance of harmful substances that will dissolve, and achieve High impact strength, strong anti-yellowing ability, not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

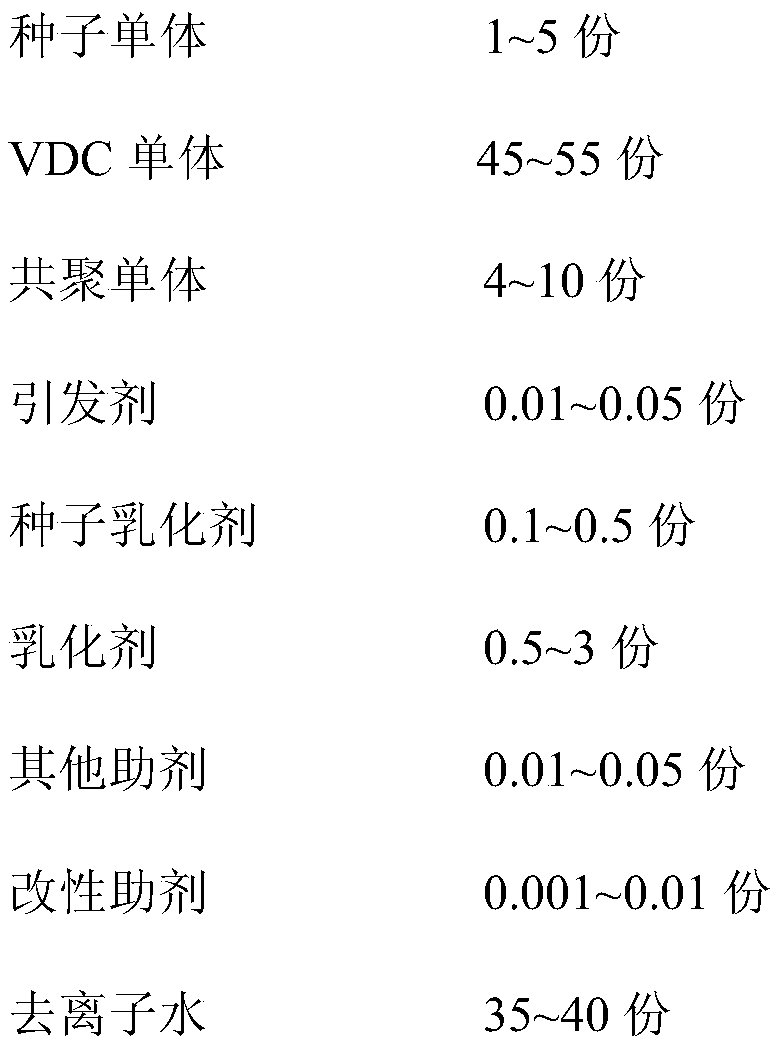

[0025] A kind of coating water-based PVDC emulsion, its raw material formula is as follows:

[0026]

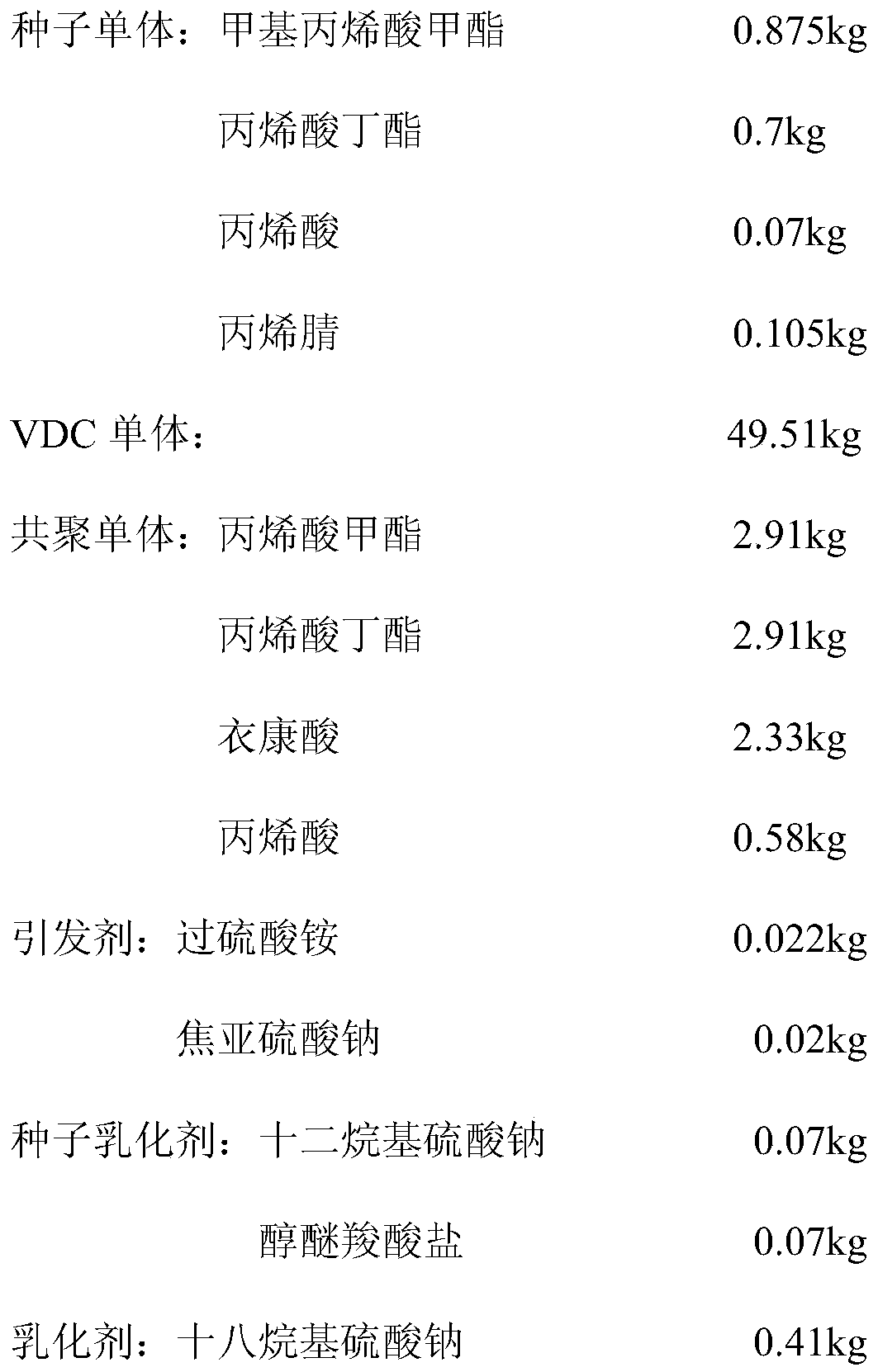

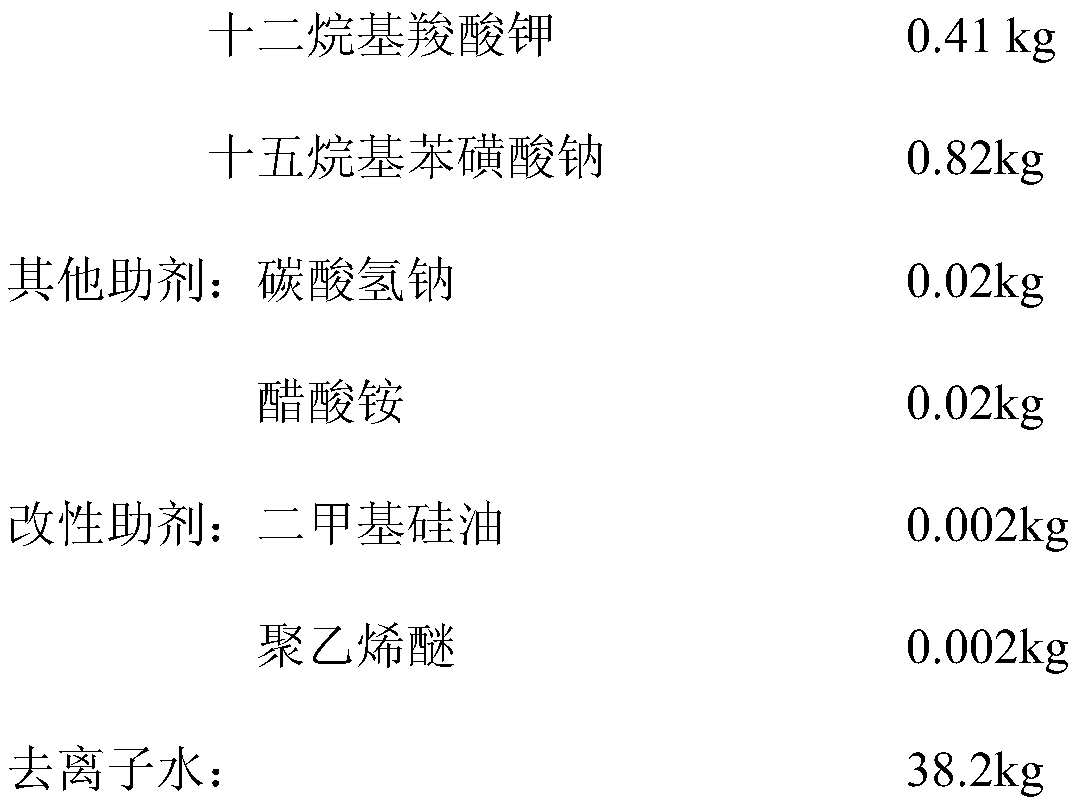

[0027]

[0028] The preparation steps are as follows:

[0029] (1) Configuration of initiator aqueous solution: Weigh 0.005kg of ammonium persulfate (APS), make ammonium persulfate aqueous solution I with 2kg of deionized water, and set aside; weigh 0.02kg of sodium metabisulfite (SMBS), and use 3kg of deionized water Water is made into sodium metabisulfite aqueous solution, and it is set aside; 0.017kg of ammonium persulfate (APS) is weighed, and 3kg of deionized water is made into ammonium persulfate aqueous solution II, and set aside;

[0030] (2) Configure the premix: 49.51kg of vinylidene chloride monomer, 2.91kg of methyl acrylate, 2.91kg of butyl acrylate, 2.33kg of itaconic acid, 0.58kg of acrylic acid, 0.41kg of octadecyl Potassium dodecyl carboxylate of sodium sulfate, 0.41kg, sodium pentadecylbenzenesulfonate of 0.82kg, sodium bicarbonate of 0.02kg, ammonium...

Embodiment 2

[0035] A kind of coating water-based PVDC emulsion, its raw material formula is as follows:

[0036]

[0037]

[0038] The preparation method is the same as in Example 1, and the performance parameters of the emulsion are shown in Table 1.

Embodiment 3

[0040] A kind of coating water-based PVDC emulsion, its raw material formula is as follows:

[0041]

[0042]

[0043] The preparation method is the same as in Example 1, and the performance parameters of the emulsion are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com