Waterborne metal cutting fluid with good rust resistance

A technology of anti-rust performance and base metal, applied in the petroleum industry, lubricating composition, etc., can solve the problems of pollution, high cost of oil-based cutting fluid, rust prevention, and unsatisfactory lubricating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

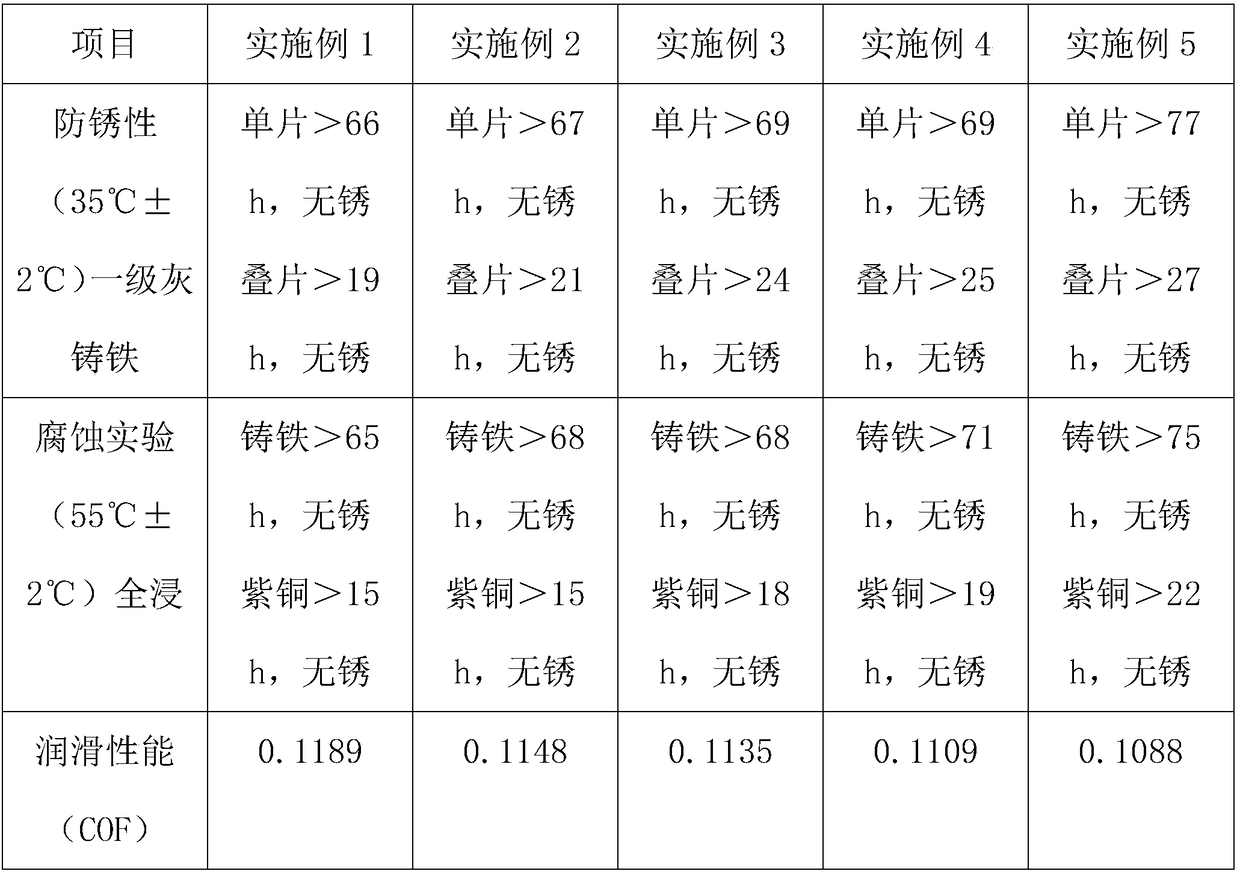

Examples

Embodiment 1

[0013] A water-based metal cutting fluid with excellent antirust performance, comprising by weight: 15 parts of naphthenic base oil, 12 parts of composite antirust agent, 4 parts of diethanolamine borate, 5 parts of thiourea, triethanolamine oleate 12 parts, 14 parts of polyethylene glycol, 1 part of aminomethyl propanol, 2 parts of simethicone, 0.3 parts of tolyltriazole, 1 part of methylenebismorpholine, and 20 parts of water.

[0014] The composite antirust agent is composed of organic acid triethanolamine, polyvinyl alcohol, and borax in a weight ratio of 20:16:6.

[0015] Synthetic method of organic acid triethanolamine: After mixing sebaceous acid and triethanolamine, heat in a water bath and keep stirring, the reaction temperature is controlled at 80°C, react for 45 minutes, and cool to room temperature to obtain the product organic acid triethanolamine.

Embodiment 2

[0017] A water-based metal cutting fluid with excellent antirust performance, comprising by weight: 35 parts of naphthenic base oil, 3 parts of composite antirust agent, 8 parts of diethanolamine borate, 2 parts of thiourea, triethanolamine oleate 16 parts, 8 parts of polyethylene glycol, 8 parts of aminomethyl propanol, 0.2 parts of simethicone, 2 parts of tolyltriazole, 0.2 parts of methylenebismorpholine, 50 parts of water.

[0018] The compound antirust agent is composed of organic acid triethanolamine, polyvinyl alcohol and borax in a weight ratio of 25:12:9.

[0019] Synthetic method of organic acid triethanolamine: After mixing sebaceous acid and triethanolamine, heat in a water bath and keep stirring, the reaction temperature is controlled at 87°C, react for 35 minutes, and cool to room temperature to obtain the product organic acid triethanolamine.

Embodiment 3

[0021] A water-based metal cutting fluid with excellent antirust performance, comprising by weight: 20 parts of naphthenic base oil, 10 parts of composite antirust agent, 5 parts of diethanolamine borate, 4 parts of thiourea, triethanolamine oleate 13 parts, 12 parts of polyethylene glycol, 3 parts of aminomethylpropanol, 1.8 parts of simethicone, 0.5 parts of tolyltriazole, 0.9 parts of methylenebismorpholine, and 25 parts of water.

[0022] The composite antirust agent is composed of organic acid triethanolamine, polyvinyl alcohol, and borax in a weight ratio of 22:15:7.

[0023] Synthetic method of organic acid triethanolamine: After mixing sebaceous acid and triethanolamine, heat in a water bath and keep stirring, control the reaction temperature between 82°C, react for 43 minutes, and cool to room temperature to obtain the product organic acid triethanolamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com