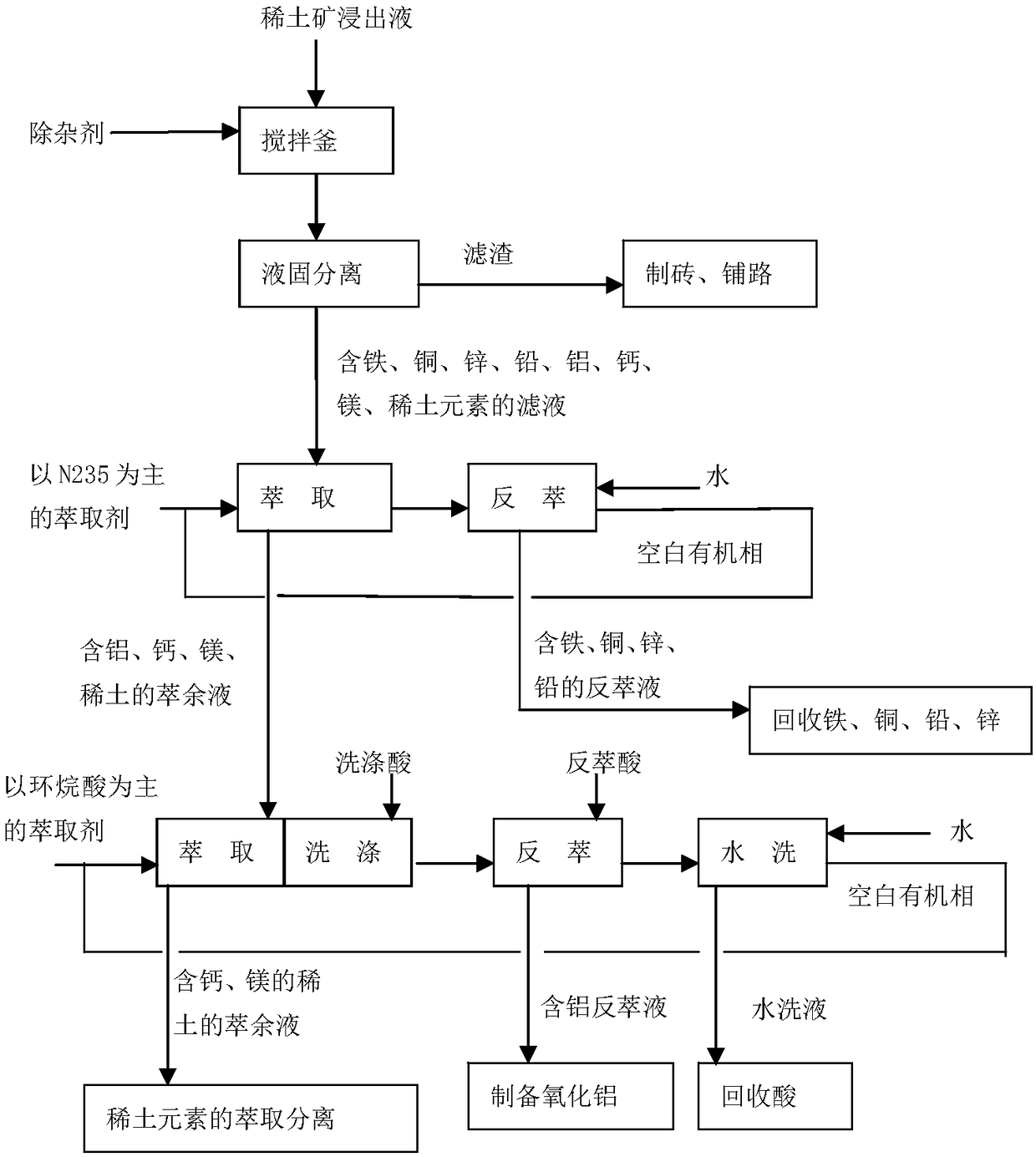

Method for removing impurities from rare earth ore leachate

A rare earth ore and leaching solution technology, which is applied in the direction of improving process efficiency, can solve the problems of reduced extraction capacity, prolonging phase separation time, and long phase separation time, so as to reduce alkali consumption, increase extraction capacity, and reduce acid consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The parameters of rare earth ore leachate: the acidity is 5mol / L, which contains 15 kinds of rare earth elements such as La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y, and Contains Fe, Al, Si, Cu, Pb, Zn, Ca, Mg and other non-rare earth impurity elements and some suspended solids, sediment and other impurities, among which the total concentration of rare earth is 1.4mol / L, the concentration of Fe is 2g / L, and the concentration of Al The concentration of Si is 6g / L, the concentration of Si is 0.3g / L, the concentration of Ca is 9g / L, the concentration of Mg is 2g / L, and the concentrations of Cu, Pb and Zn are 0.03g / L, 0.05g / L and 1g / L respectively.

[0035] A method for removing impurities in a leach solution of a rare earth ore, comprising the steps of simultaneously removing suspended solids, silt and silicon, the steps being specifically:

[0036] Select polyacrylamide (molecular weight 3,000,000 Daltons) and polyaluminum chloride as the mixed impurity remo...

Embodiment 2

[0043] Parameters of rare earth ore leach solution: acidity is 8mol / L, which contains 15 kinds of rare earth elements such as La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y, and Contains Fe, Al, Si, Cu, Pb, Zn, Ca, Mg and other non-rare earth impurity elements and some suspended solids, sediment and other impurities, of which the total concentration of rare earth is 1.7mol / L, the concentration of Fe is 1.6g / L, Al Concentration is 5g / L, Si concentration is 1.5g / L, Ca concentration is 5g / L, Mg concentration is 4g / L, Cu, Pb and Zn concentrations are 0.3g / L, 0.9g / L and 0.7g / L, respectively. L.

[0044] A method for removing impurities in a leach solution of a rare earth ore, comprising the steps of simultaneously removing suspended solids, silt and silicon, the steps being specifically:

[0045] Select polyacrylamide (molecular weight 6 million Daltons) and barium chloride as the mixed impurity remover, wherein the weight ratio of polyacrylamide and barium chloride is ...

Embodiment 3

[0049] Parameters of rare earth ore leach solution: acidity is 2mol / L, which contains 15 kinds of rare earth elements such as La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y, and Contains Fe, Al, Si, Cu, Pb, Zn, Ca, Mg and other non-rare earth impurity elements and some suspended solids, sediment and other impurities, of which the total concentration of rare earth is 1.25mol / L, the concentration of Fe is 6g / L, and the concentration of Al The concentration of Si is 2.8g / L, the concentration of Si is 1.1g / L, the concentration of Ca is 25g / L, the concentration of Mg is 8g / L, and the concentrations of Cu, Pb and Zn are 2.1g / L, 0.09g / L and 1.7g / L respectively. L.

[0050] A method for removing impurities in a leach solution of a rare earth ore, comprising the steps of simultaneously removing suspended solids, silt and silicon, the steps being specifically:

[0051] Select polyferric sulfate and diatomite as the mixed impurity remover, wherein the weight ratio of polyferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com