Cellulose diacetate fibrous membrane and preparing method thereof

A technology of cellulose diacetate and fiber film, which is used in fiber processing, non-woven fabric, filament/thread forming, etc., can solve problems such as long process flow, and achieve the effects of low cost, large specific surface area, and easy control of process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present embodiment provides a kind of porous flat section cellulose diacetate fiber membrane, and its preparation method is as follows:

[0026] (1) The composition of the spinning solution: the mass concentration of cellulose diacetate (relative average molecular weight: 40,000) is 8%, the mass of polyethylene oxide is 5% (relative to the mass of cellulose diacetate), the total mass of acetone and water The concentration is 92%, and the volume ratio of acetone and water is 5:1.

[0027] (2) Spinning process: Under the control of the flow pump, the cellulose diacetate solution is extruded from the round metal needle of the 10ml syringe at a speed of 2.5ml / h, and is accelerated to move forward under the action of an electric field force of 15kv. The atmospheric environment with a relative humidity of 29% and a temperature of 21°C finally falls on a metal receiving device with an aluminum foil at a distance of 14cm from the metal needle to obtain a porous flat-section...

Embodiment 2

[0031] The steps of preparing porous flat section cellulose diacetate fiber membrane in this embodiment are as follows:

[0032] (1) The composition of the spinning solution: the mass concentration of cellulose diacetate (relative average molecular weight: 40,000) is 8%, the mass of polyethylene oxide is 5% (relative to the mass of cellulose diacetate), the total mass of acetone and water The concentration is 92%, and the volume ratio of acetone and water is 3:1.

[0033] (2) The spinning process is the same as in Example 1.

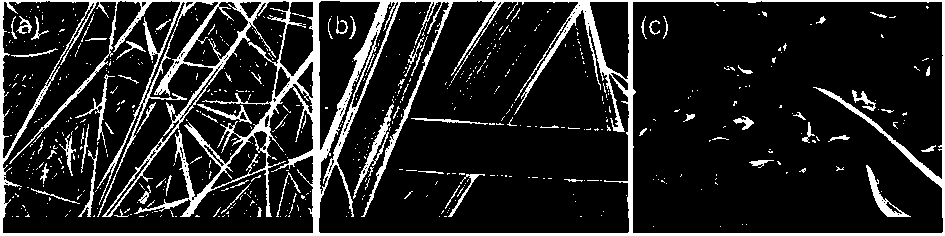

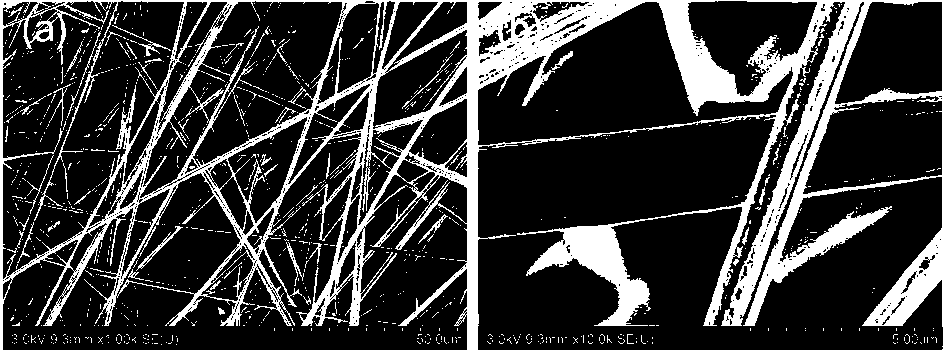

[0034] See Attachment 2, which is the scanning electron micrograph of the porous flat-section cellulose diacetate fiber membrane prepared with the mixed solvent of acetone and water at a volume ratio of 3:1 in this example, (a) is the magnification of the fiber membrane at 1000 times; (b) The magnification of the fiber membrane is 10000 times.

[0035] The pores on the surface of the fibers constituting the fiber membrane have a pore diameter of 23.3-2...

Embodiment 3

[0037] The present embodiment prepares porous flat section cellulose diacetate fiber membrane as follows:

[0038] The composition of spinning solution: the mass concentration of cellulose diacetate (relative average molecular weight is 40000) is 6%, the mass of polyethylene oxide is 15% (relative to the mass of cellulose diacetate), the total mass concentration of acetone and dichloromethane 94%, the volume ratio of acetone and dichloromethane is 2:1.

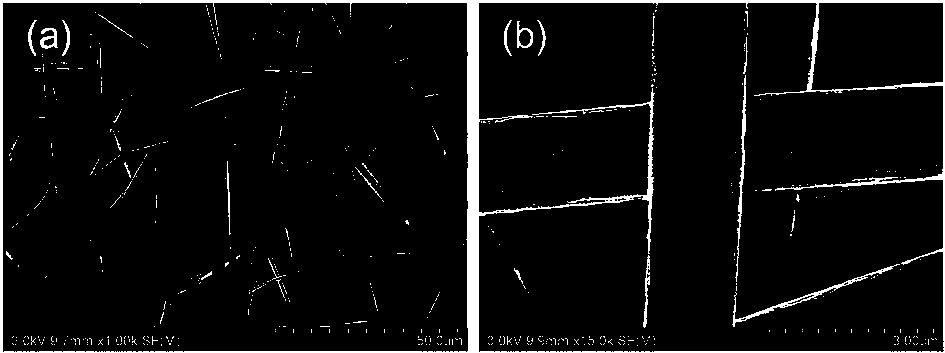

[0039] Spinning process: Under the control of the flow pump, the cellulose diacetate solution is extruded from the circular metal needle of the 10ml syringe at a speed of 1ml / h, and is accelerated to move forward under the action of an electric field force of 12kv, and the relative humidity is 81 %, the atmospheric environment with a temperature of 26°C, finally falls on the metal receiving device with aluminum foil at a distance of 12cm from the metal needle, and obtains a porous flat-section cellulose diacetate fiber membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com