Method for preparing hafnium-oxide-based thin ferroelectric film by using all-inorganic precursor solution and application

A technology of precursor solution and ferroelectric thin film, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of not having ferroelectric properties, and achieve the effects of reducing harsh requirements, simplifying the preparation process, and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

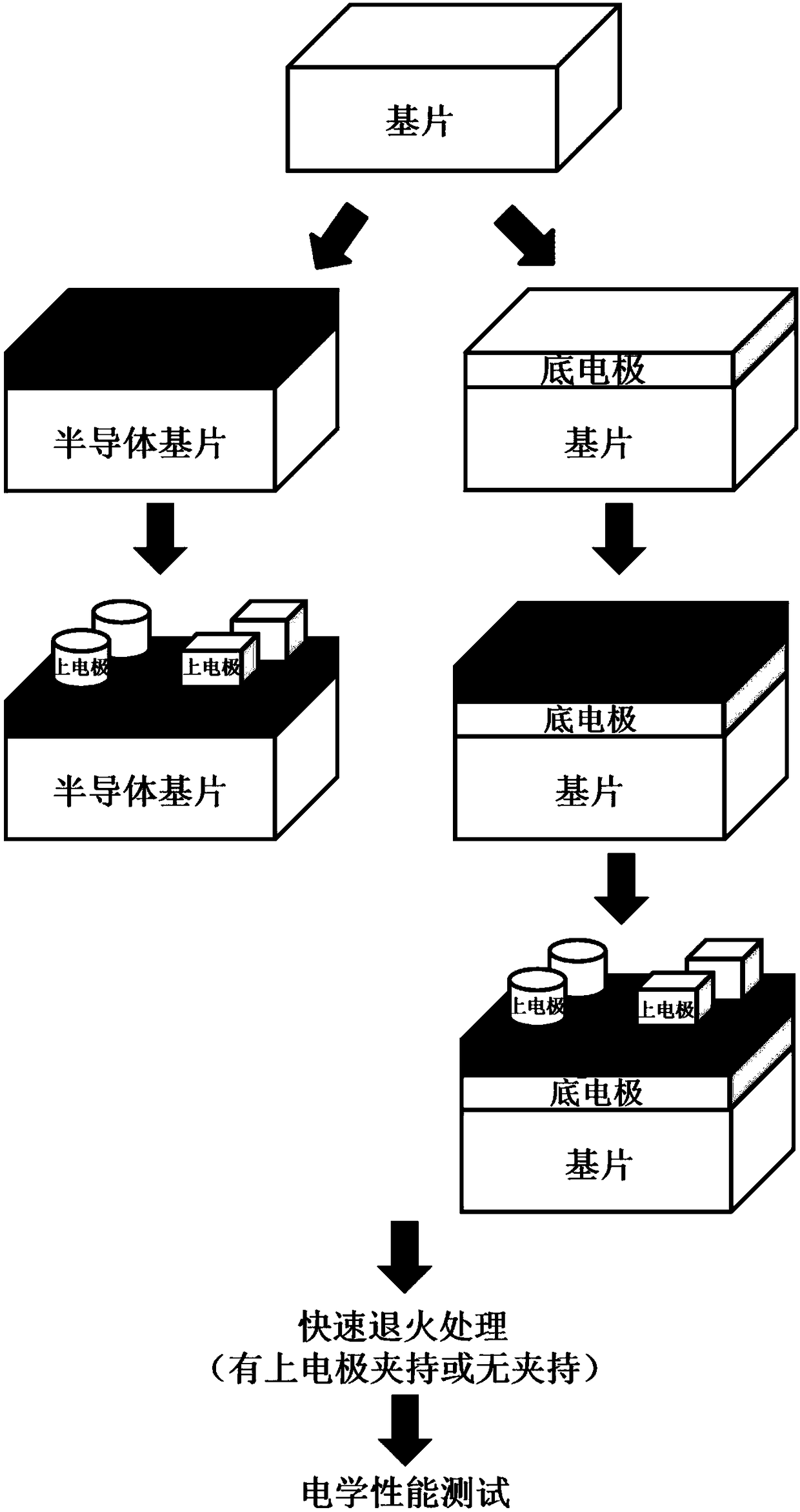

Method used

Image

Examples

Embodiment 1

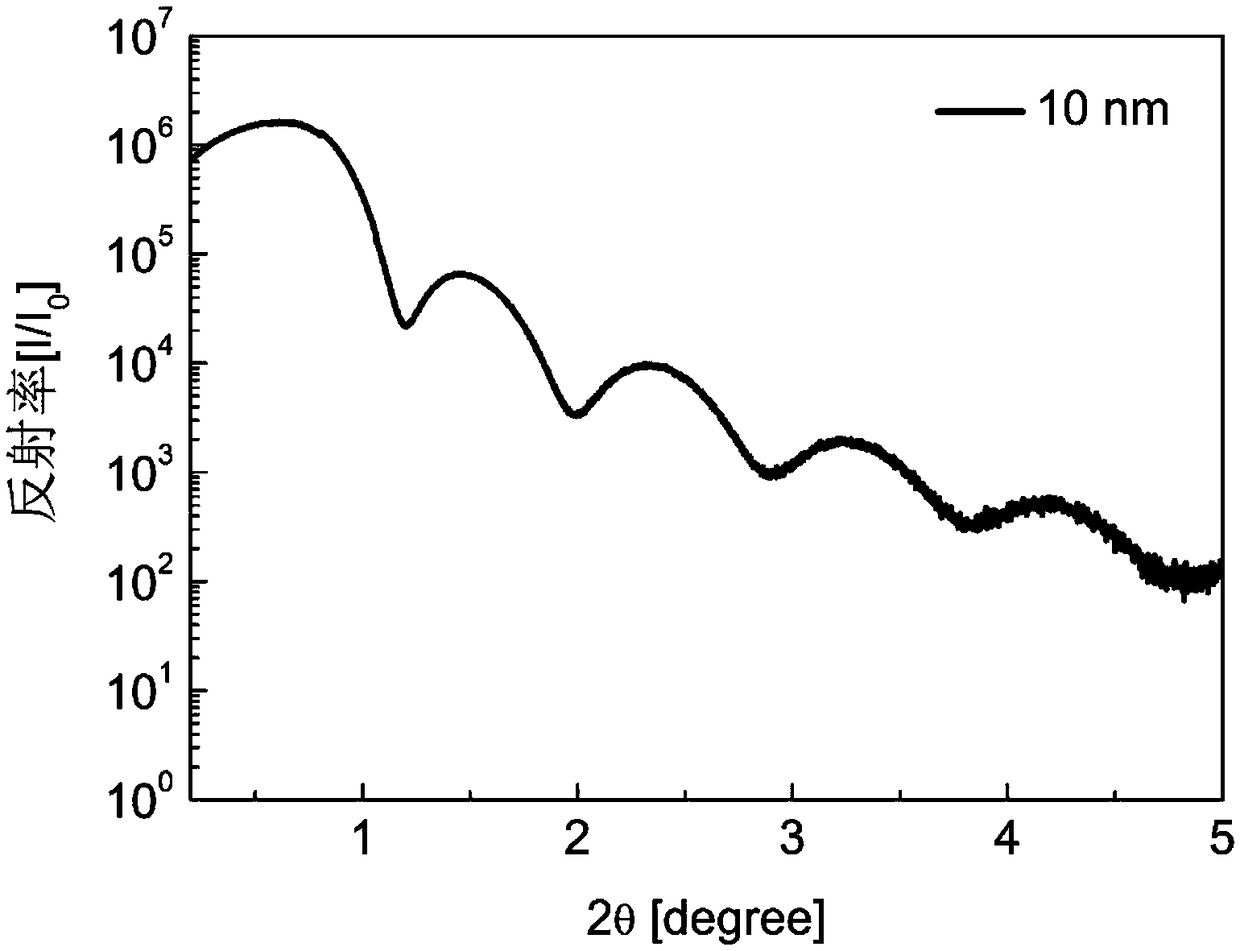

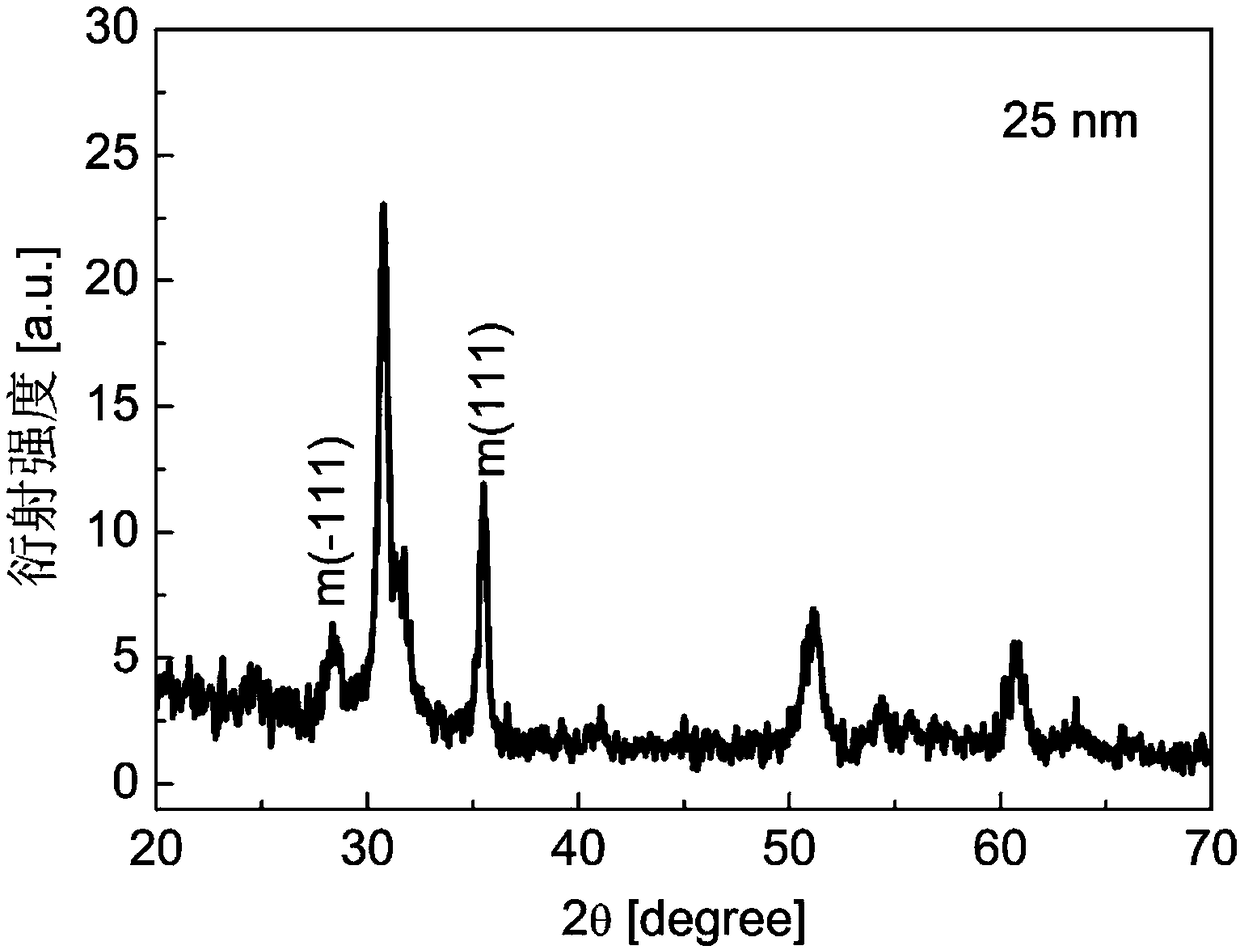

[0040] HfOCl 2 ·8H 2 O and ZrOCl 2 ·8H 2 The O precursor raw material is fully dissolved in deionized water to form a transparent solution with a Zr doping concentration of 40mol%, and 1mol / L ammonia water is added dropwise to the above solution while stirring, ammonia water and Hf 4+ The molar concentration ratio was 2.5:1, forming a white precipitate with a measured pH of 8.0; the precipitate was then centrifuged with deionized water to remove residual chloride ions (Cl - ), and finally 2mol / LHNO 3 and 10mol / LH 2 o 2 Mix to form debonder, HNO 3 with Hf 4 + The molar concentration ratio of the solution is 1.1:1, added to the centrifuged precipitate, and continued magnetic stirring for about 12 hours. After standing for a period of time, a clear and transparent sol was obtained. The pH value of the clear sol was controlled to be 0.7; Type silicon substrates were cleaned by standard RCA steps, and then the dried substrates were subjected to plasma bombardment to increa...

Embodiment 2

[0042] HfOCl 2 ·8H 2 The O precursor raw material is fully dissolved in deionized water, and 1mol / L ammonia water is added dropwise to the above solution while stirring, ammonia water and Hf 4+ The molar concentration ratio was 3:1, resulting in a white precipitate with a measured pH of 9.0; the precipitate was then centrifuged with deionized water to remove residual chloride ions (Cl - ), and finally 2mol / LHNO 3 and 10mol / LH 2 o 2 Mix to form debonder, HNO 3 with Hf 4+ The molar concentration ratio of the solution was 1.5:1, added to the precipitate after centrifugation, continued magnetic stirring for about 12 hours, and obtained a clear and transparent sol after standing for a period of time. The pH value of the clear sol was controlled to be 0.8, and Ba(NO 3 ) 2 Add the above hafnium sol to form a transparent sol with a Ba doping concentration of 7.5 mol%. Subsequently, the clean p-type germanium sheet is cleaned by standard RCA steps, and then the dried substrate i...

Embodiment 3

[0044] HfOCl 2 ·8H 2 The O precursor raw material is fully dissolved in deionized water, and 1mol / L ammonia water is added to the above solution while stirring, ammonia water and Hf 4+ The molar concentration ratio was 2.8:1, forming a white precipitate with a measured pH of 8.5; the precipitate was then centrifuged with deionized water to remove residual chloride ions (Cl - ), and finally 2mol / LHNO 3 and 10mol / LH 2 o 2 Mix to form debonder, HNO 3 with Hf 4+ The molar concentration ratio of the solution was 1.2:1, added to the precipitate after centrifugation, continued magnetic stirring for about 12 hours, and obtained a clear and transparent sol after standing for a period of time. The pH value of the clear sol was controlled to be 0.7, and the Sr(NO 3 ) 2 Add the above hafnium sol to form a transparent sol with Sr doping concentration of 11mol%. Subsequently, the clean glass substrate was cleaned by standard RCA steps, and then the TiN metal bottom electrode was depo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com