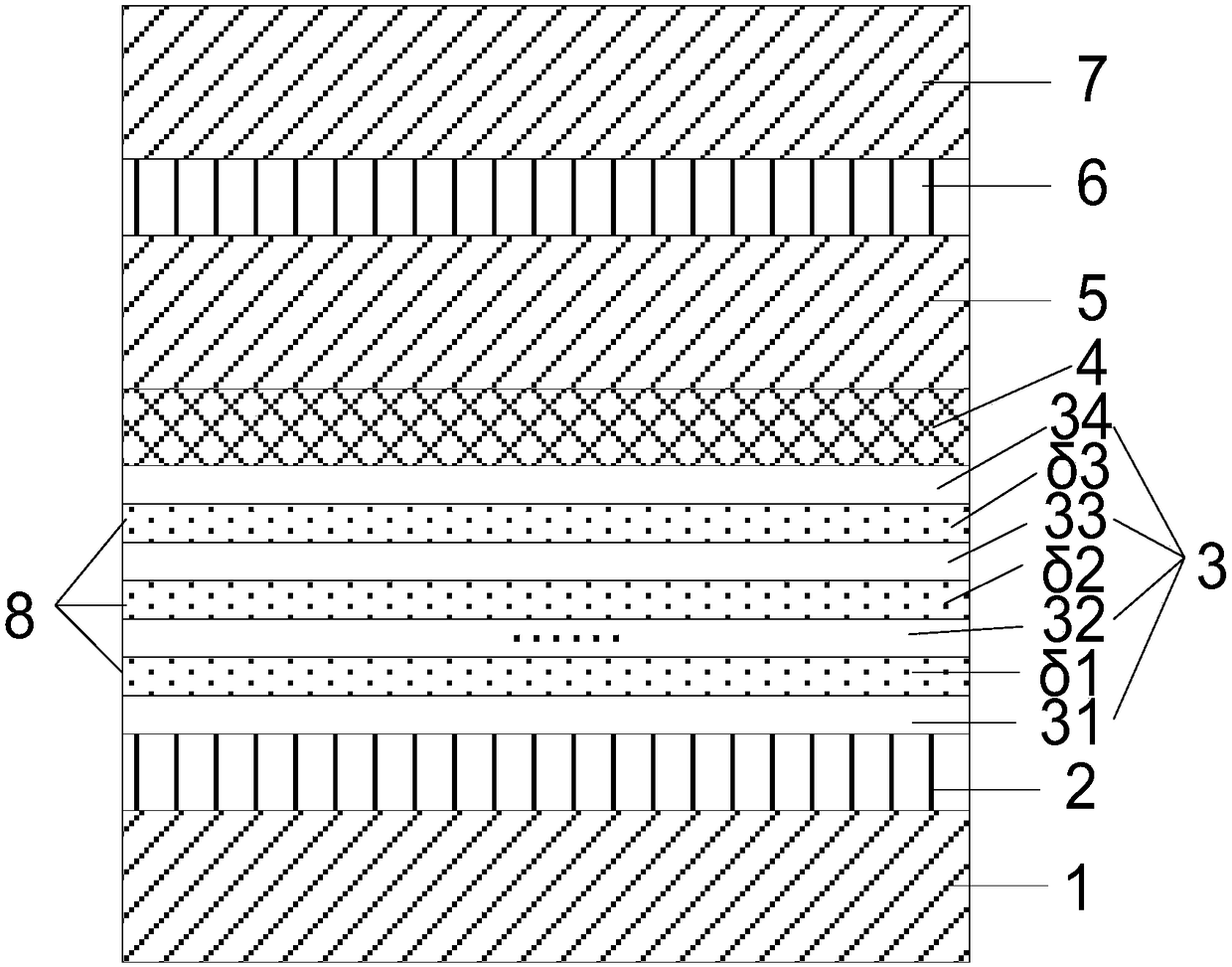

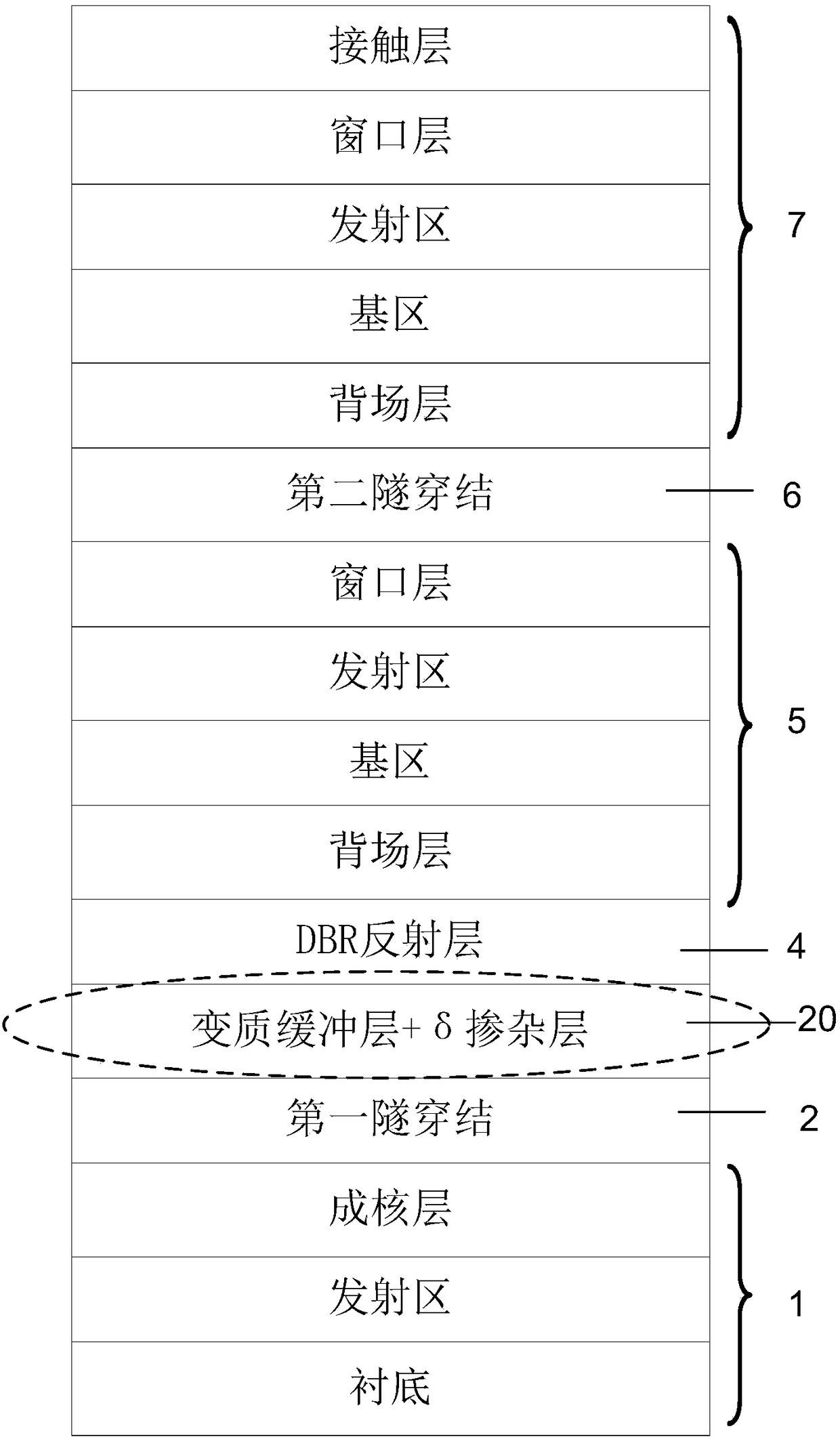

Lattice mismatched multi-junction solar cell and manufacturing method thereof

A solar cell, lattice mismatch technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as lattice mismatch, surface roughness, wafer warpage, etc., to improve the effect of blocking dislocations, reduce Dislocation density, the effect of improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

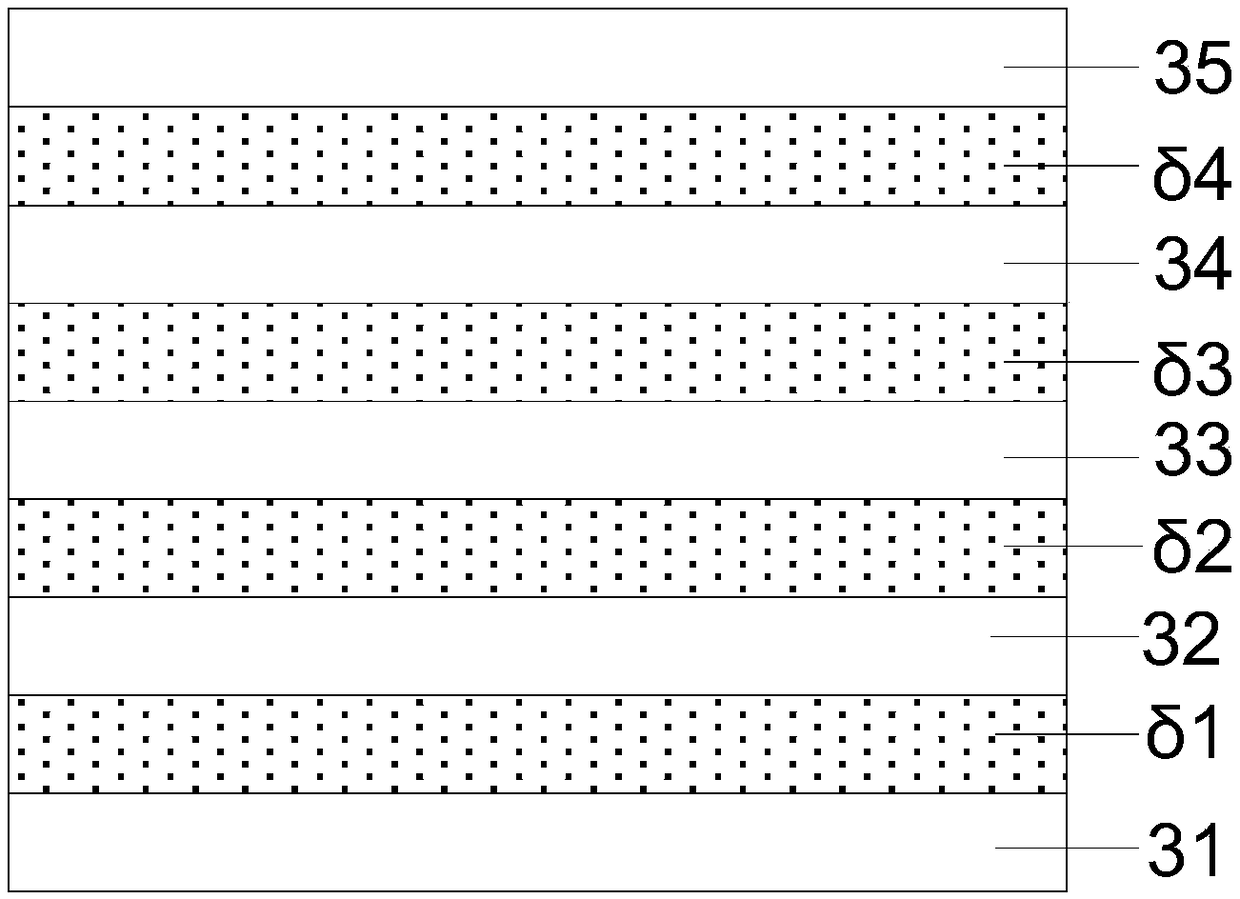

[0044] As mentioned in the background technology section, the metamorphic buffer layer in the prior art is formed by compositional transformation method, although the dislocations generated by the mismatch can be limited to the interface between two adjacent buffer layers and do not extend upward into the active cell. area, but this technique is not optimal for stress relief. The stress that has not been fully released will continue to release the stress by forming surface fluctuations of the epitaxial layer to cause surface roughness, and the residual stress in the epitaxial layer will also cause the wafer to warp. Moreover, the number of steps of the component-level modification method, the component-level variables of each layer, and the thickness of the steps need to be finely optimized, resulting in a narrow process window, and process fluctuations in production will lead to poor effects of blocking dislocations and releasing stress. .

[0045] However, the inventors fou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Single layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com