Method for preparing ASA-based graft copolymer, method for preparing thermoplastic ASA-based resin composition comprising same, and method for manufacturing ASA-based molded product

A technique of graft copolymer and preparation steps, which is applied in the fields of preparation of ASA graft copolymer, preparation of thermoplastic ASA resin composition containing it and preparation of ASA molded products, can solve the problem of being easily affected by ultraviolet light, ABS resin Poor weather resistance, chemical instability and other problems, to achieve the effect of excellent thermal stability, excellent appearance characteristics, high surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

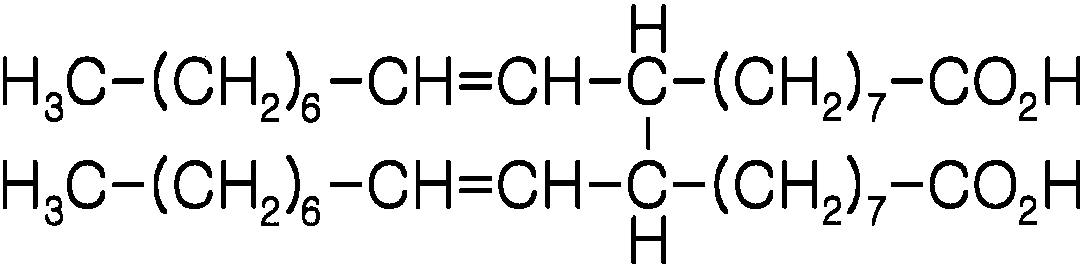

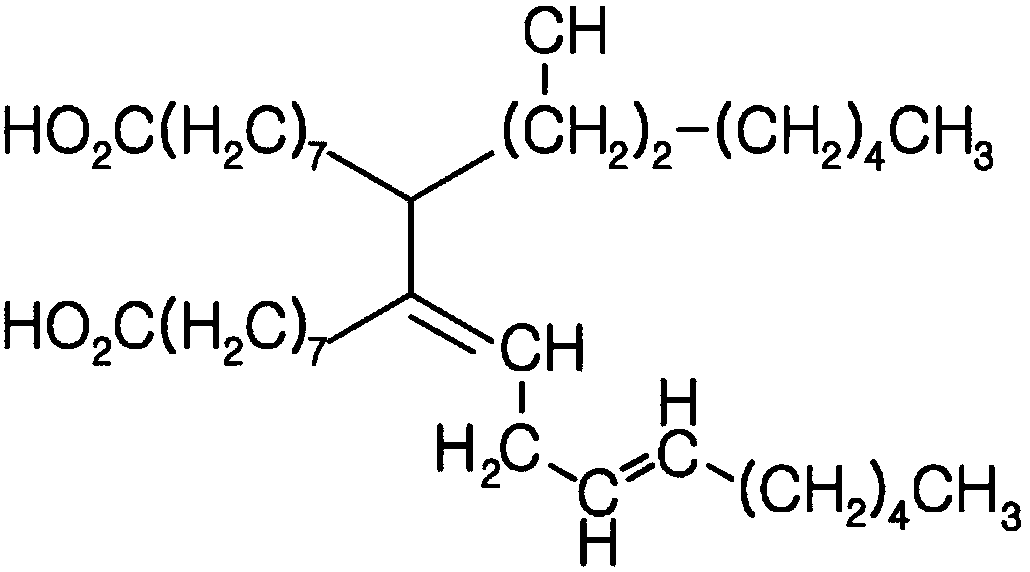

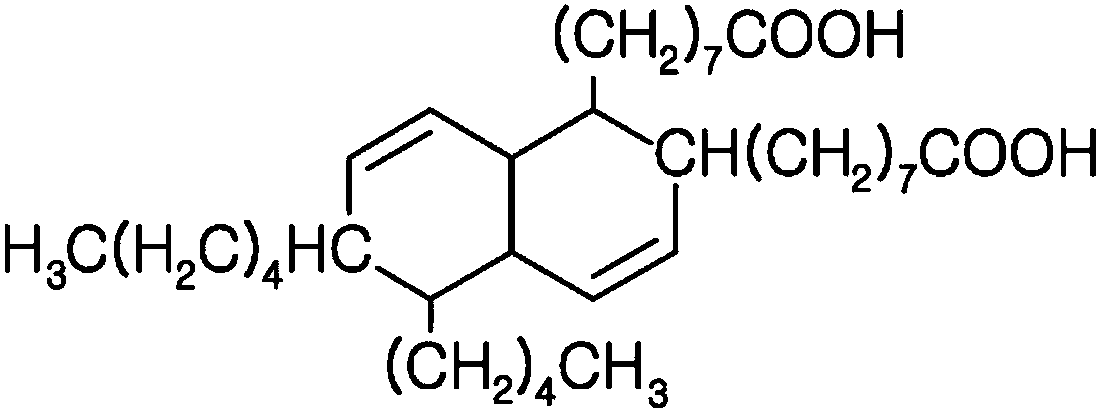

[0026] The preparation method of ASA graft copolymer according to the present invention comprises: a) seed preparation step, wherein make one or more selected from aromatic vinyl monomers, vinyl cyano monomers and alkyl acrylate monomers a monomer is polymerized to prepare a seed; b) a core preparation step, wherein an alkyl acrylate monomer is added and polymerized in the presence of the prepared seed to prepare a core; and c) a shell preparation step, wherein in the presence of the prepared core Adding one or more monomers selected from aromatic vinyl monomers and vinyl cyano monomers and an emulsifier and performing graft polymerization to prepare a shell, wherein the emulsifier contains Atomic polyfunctional carboxylic acid or salt thereof, and the average size of the prepared shell is 80 to 150 nm (larger than the average size of the core).

[0027] For example, the emulsifier may contain a polyfunctional carboxylic acid or a salt thereof having 20 to 60 carbon atoms, 20 ...

Embodiment 1

[0107] 1. Polymer Seed Preparation Steps

[0108] 6 parts by weight of butyl acrylate, 1.5 parts by weight of sodium lauryl sulfate, 0.04 parts by weight of ethylene glycol dimethacrylate, 0.02 parts by weight of allyl methacrylate, 0.1 parts by weight of Potassium and 45 parts by weight of distilled water were simultaneously added to the nitrogen-substituted reactor, the temperature was raised to 70° C., and 0.04 parts by weight of potassium persulfate was added to the reactor to initiate polymerization. Polymerization was then continued for 1 hour.

[0109] The average size of the rubbery polymer particles obtained after completion of the reaction was 40 nm.

[0110] 2. Polymer core preparation steps

[0111] The butyl acrylate of 44 parts by weight, the sodium lauryl sulfate of 0.5 parts by weight, the ethylene glycol dimethacrylate of 0.2 parts by weight, the allyl methacrylate of 0.2 parts by weight, the distilled water of 30 parts by weight and 0.05 parts by weight of...

Embodiment 2

[0121] Except using an emulsion containing 0.4 parts by weight of mixed emulsifier FS200 (LG Household & Health Care), 0.7 parts by weight of sodium abietate, 0.1 parts by weight of TDDM and 0.05 parts by weight of cumene hydroperoxide instead of the polymer of Example 1 A graft copolymer latex was prepared in the same manner as in Example 1 except for the emulsion in the graft shell preparation step.

[0122] The polymerization conversion rate of the prepared graft copolymer latex was 98.5%, and the average size of the final particles was 105nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com