Method and equipment for producing high temperature gypsum from industrial byproduct gypsum

A technology for industrial by-product gypsum and gypsum, applied in the field of high-temperature gypsum, can solve problems such as complex maintenance of process equipment, achieve low investment, high efficiency, and facilitate the promotion and application of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

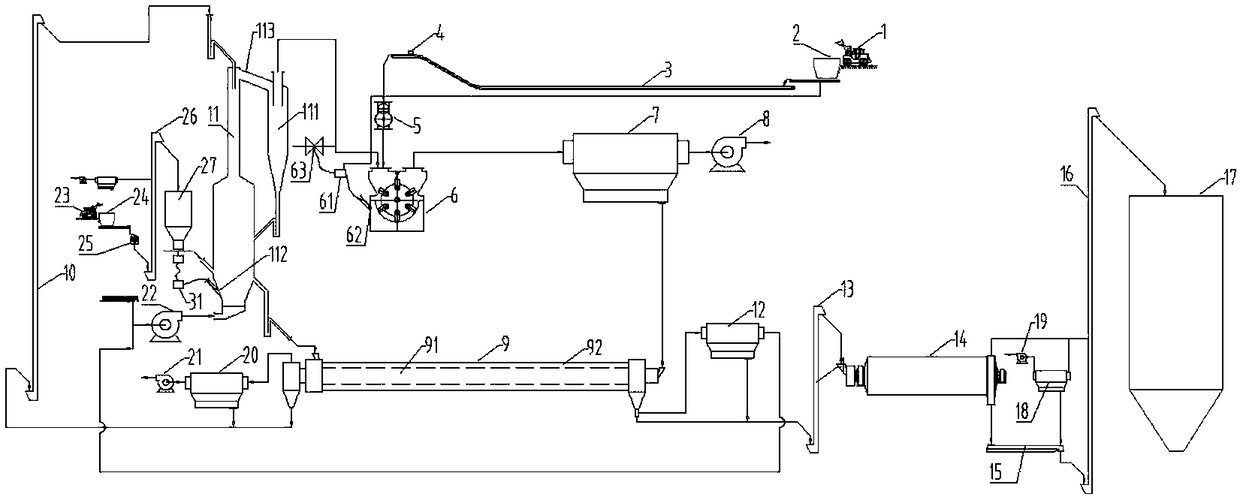

[0092] Get 500Kg industrial by-product phosphogypsum, adopt such as figure 1The equipment shown in the figure continuously produces high-temperature gypsum on-line. The gypsum is transported to the box-type feeding seasoning machine 2 for buffering through the loader 1. Machine 5 and belt conveyor 3 are equipped with permanent magnet iron remover 4 to remove iron impurities; the gypsum in the air lock feeder 5 enters the dryer 6, and the controller 61 is set to control the drying temperature to 500°C. The time for removing free water at high temperature is between 3 and 5 seconds. The pulverized and dried gypsum is separated and collected in the dust collector 7, the tail gas is discharged through the fan 8, and the gypsum in the dust collector 7 enters the inner cylinder 91 and the outer cylinder 91. The calcined gypsum in the cylinder 92 is heat-exchanged and further dehydrated. The temperature of the gypsum in the inner cylinder 91 is 100-550°C. The dehydrated gypsum part e...

Embodiment 2

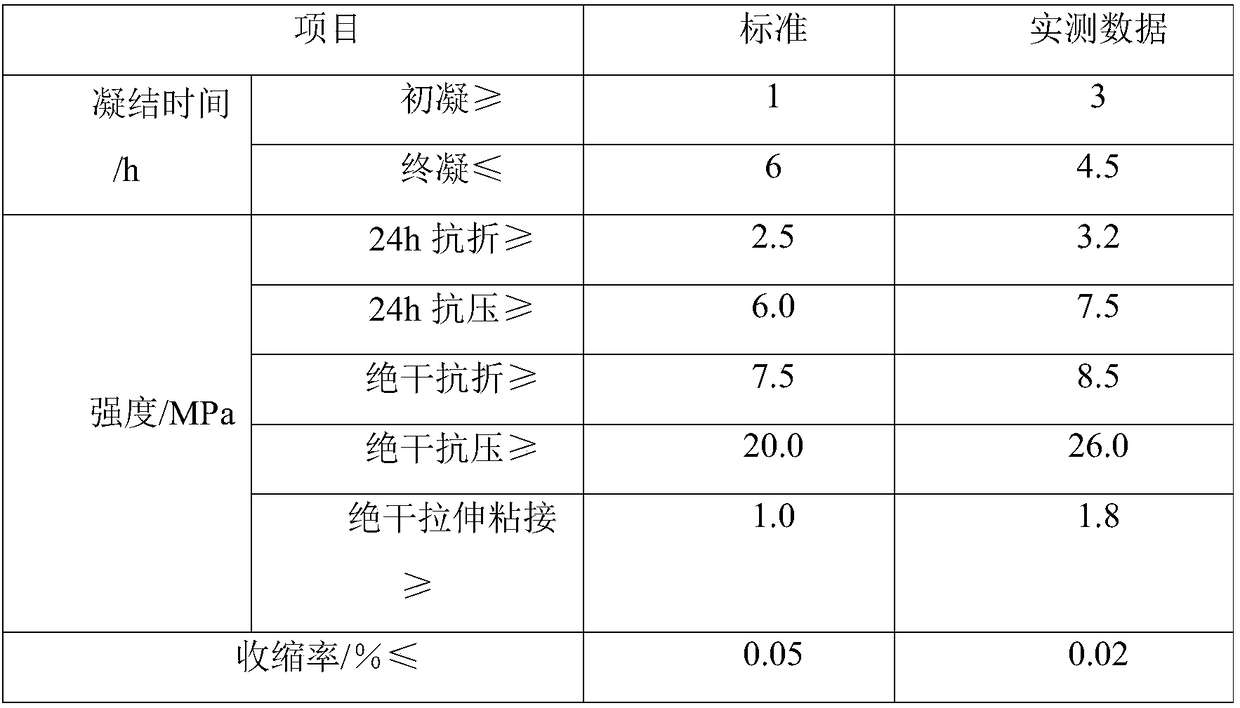

[0100] Take 10Kg of the high-temperature gypsum powder prepared in Example 1 and add activators, admixtures, admixtures, aggregates, etc. to obtain plastering gypsum, and test the obtained plastering gypsum. The test results are shown in Table 2.

[0101] Table 2 Example 2 High-temperature gypsum preparation plastering gypsum performance

[0102]

[0103]

Embodiment 3

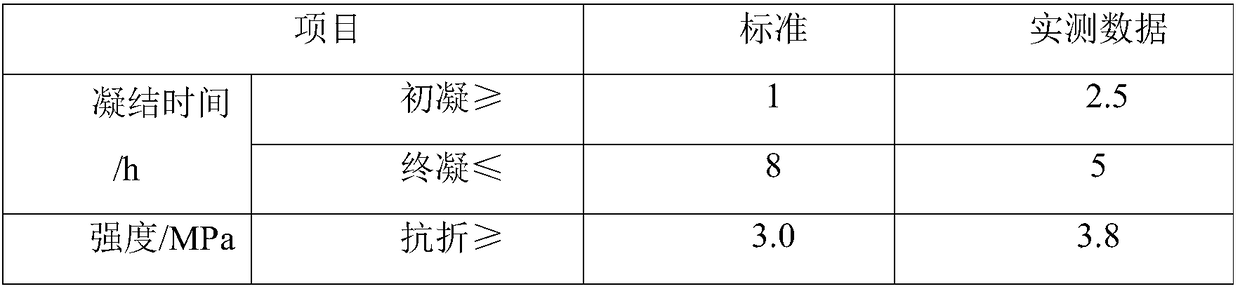

[0105] The high-temperature gypsum powder prepared in Example 1 was added to the activator for data testing, and the testing results are shown in Table 3.

[0106] Table 3 Example 3 high temperature gypsum properties

[0107]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com