Method for preparing light high-strength concrete

A concrete, high-strength technology, applied in the field of light-weight and high-strength concrete preparation, can solve problems such as damage, fragmentation, and bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

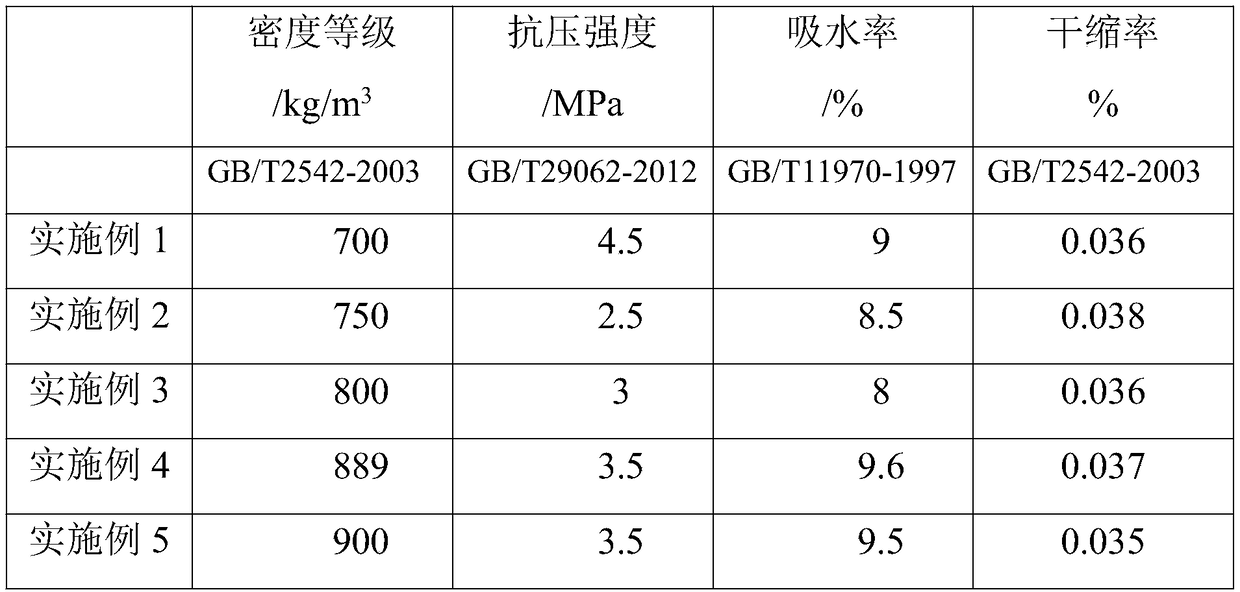

Examples

preparation example Construction

[0017] The present invention also provides a method for preparing the lightweight high-strength concrete, comprising the steps of:

[0018] (1) 25-45 parts by weight of fly ash, 15-35 parts by weight of cement, 15-30 parts by weight of fine sand, 5-12 parts by weight of diatomaceous earth, 3-15 parts by weight of light calcium carbonate, polymerized chloride 3-12 parts by weight of aluminum, 15-48 parts by weight of lightweight aggregate, 1-5 parts by weight of reinforcing fiber and 1-5 parts by weight of graphene oxide are uniformly mixed under mechanical stirring conditions to obtain a mixture;

[0019] (2) Disperse 0.5-1.5 parts by weight of water reducing agent and 0-5 parts by weight of other additives in water evenly, then add the above-mentioned powder material, and continue stirring for 60-150s to obtain a mixed slurry; finally, add 1-3 parts by weight of The foaming agent is added into the mixed slurry, and stirred evenly to obtain the precursor of the concrete materi...

Embodiment 1

[0023] (1) 35 parts by weight of fly ash, 25 parts by weight of cement, 23 parts by weight of fine sand, 8 parts by weight of diatomaceous earth, 8 parts by weight of light calcium carbonate, 6 parts by weight of polyaluminum chloride, and 10 parts by weight of clay ceramsite (1~5mm), 10 parts by weight of pumice (1~5mm), 10 parts by weight of polyethylene foam, 5 parts by weight of polypropylene fiber and 3 parts by weight of graphene oxide are mixed under mechanical stirring conditions to obtain a mixture;

[0024] (2) 1.2 parts by weight of polycarboxylate superplasticizer (model PASP-Ca, purchased from Shandong Yuanlian Chemical Co., Ltd.), 1 part by weight of sodium dodecylbenzenesulfonate, 0.5 parts by weight of calcium stearate, 0.5 parts by weight Parts by weight of hydroxyethyl methyl reinforced cellulose ether, 0.5 parts by weight of sodium aluminate and 0.5 parts by weight of sodium gluconate are uniformly dispersed in water, and then added to the above powder China,...

Embodiment 2

[0027] (1) 25 parts by weight of fly ash, 35 parts by weight of cement, 15 parts by weight of fine sand, 12 parts by weight of diatomaceous earth, 5 parts by weight of polyethylene foam plastics (1 ~ 5mm), 10 parts by weight of castor stalks, 12 parts by weight of polyaluminum chloride, 1 part by weight of polyhexamethylene adipamide fiber and 5 parts by weight of graphene oxide are uniformly mixed under mechanical stirring conditions to obtain a mixture;

[0028] (2) 1.5 parts by weight of polycarboxylate water reducer (model PASP-Ca, purchased from Shandong Yuanlian Chemical Co., Ltd.), 1 part by weight of sodium dodecylbenzenesulfonate, 1 part by weight of calcium stearate, 1 part by weight of hydroxyethyl methyl reinforced cellulose ether, 1 part by weight of sodium aluminate and 1 part by weight of sodium gluconate are uniformly dispersed in water, then add the above powder, and continue to stir for 60-150s to obtain a mixed slurry; finally, mix 1 Parts by weight of hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com