A kind of composite phosphate microwave dielectric ceramic and its preparation method

A technology of microwave dielectric ceramics and phosphate series, applied in the field of microwave dielectric ceramics, can solve the problems of high energy consumption, high sintering temperature, and low quality factor, and achieve the effects of low loss, simple preparation process, and no pollution in the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing a composite phosphate-based microwave dielectric ceramic, which is characterized in that the specific preparation steps are as follows:

[0031] (1) The chemical raw material will be the chemical raw material will be CaCO 3 , La 2 o 3 , SiO 2 、 Bi 2 o 3 、Pr 2 o 3 and NH 4 h 2 PO 4 stoichiometric Ca 4 (La 4-x Bi x PR 2 ) (SiO 4 ) 4 (PO 4 ) 2 o 2 (0.2≤x≤0.8) Stoichiometric composition Weighing ingredients into pre-grinding ingredients;

[0032] (2) Put the pre-grinding ingredients into a ball milling tank for ball milling, and place them in a drying oven to dry into powder after ball milling; wherein the ratio of pre-grinding ingredients, zirconia balls and deionized water inside the ball milling tank is 1:2.5:3, The ball milling time is 14-18h, and the drying temperature is 120°C;

[0033] (3) Calcining the powder to obtain calcined powder; wherein the calcining temperature is 1150°C, and the ...

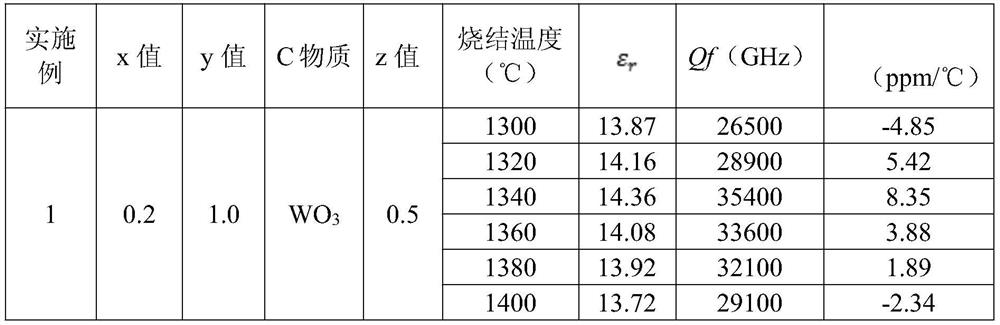

Embodiment 1

[0040] Take x=0.2, y=0.5, z=0.5, C=WO 3 ;

[0041] (1) CaCO 3 , La 2 o 3 , SiO 2 、 Bi 2 o 3 、Pr 2 o 3 , NH 4 h 2 PO 4 stoichiometric Ca 4 (La 3.8 Bi 0.2 PR 2 ) (SiO 4 ) 4 (PO 4 ) 2 o 2 Composition Weighing ingredients, after mixing, put the raw materials into the nylon tank, add zirconia balls and deionized water (the ratio of ball water is 1:2.5:3). Ball mill for 14-18 hours, place the ball-milled raw materials in an oven, and dry at 120°C;

[0042] (2) The uniformly mixed powder is calcined at 1150°C for 3h;

[0043] (3) put the calcined raw material in step (2) into the ball mill jar, and add 1.0wt% Li at the same time 2 CO 3 and 0.5 wt% WO 3 , add zirconia balls and deionized water, ball mill for 20-24 hours, dry, add PVA solution with a mass solubility of 3% to the dried powder as a binder and granulate, press into a cylindrical embryo body , the diameter of the embryo body is about 15mm, and the height is about 7.5mm;

[0044] (4) Sinter the cyl...

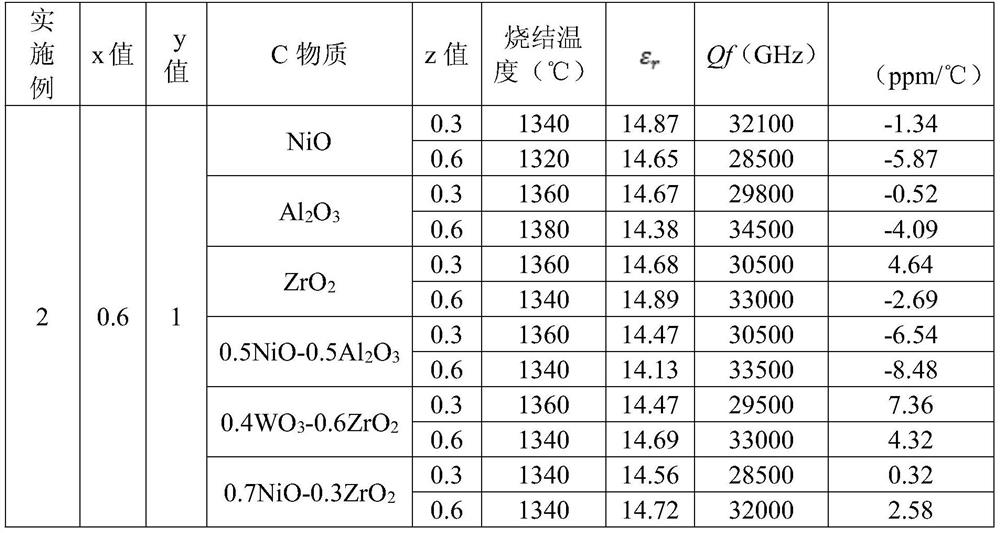

Embodiment 2

[0050] Following Example 1, on the basis of Example 1, select x=0.6, y=0.5 components to add zwt%C substances, and the rest are the same as Example 1. The test results are shown in Table 2.

[0051] The experimental result involved in table 2 embodiment 2:

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com