A ni-doped biovo 4 Thin film photoanode, its preparation method and use

A photoanode, thin film technology, applied in photosensitive equipment, photovoltaic power generation, circuits, etc., can solve the problem of not reaching the ideal value, and achieve the effect of good photoelectric performance, simple steps, and improved migration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

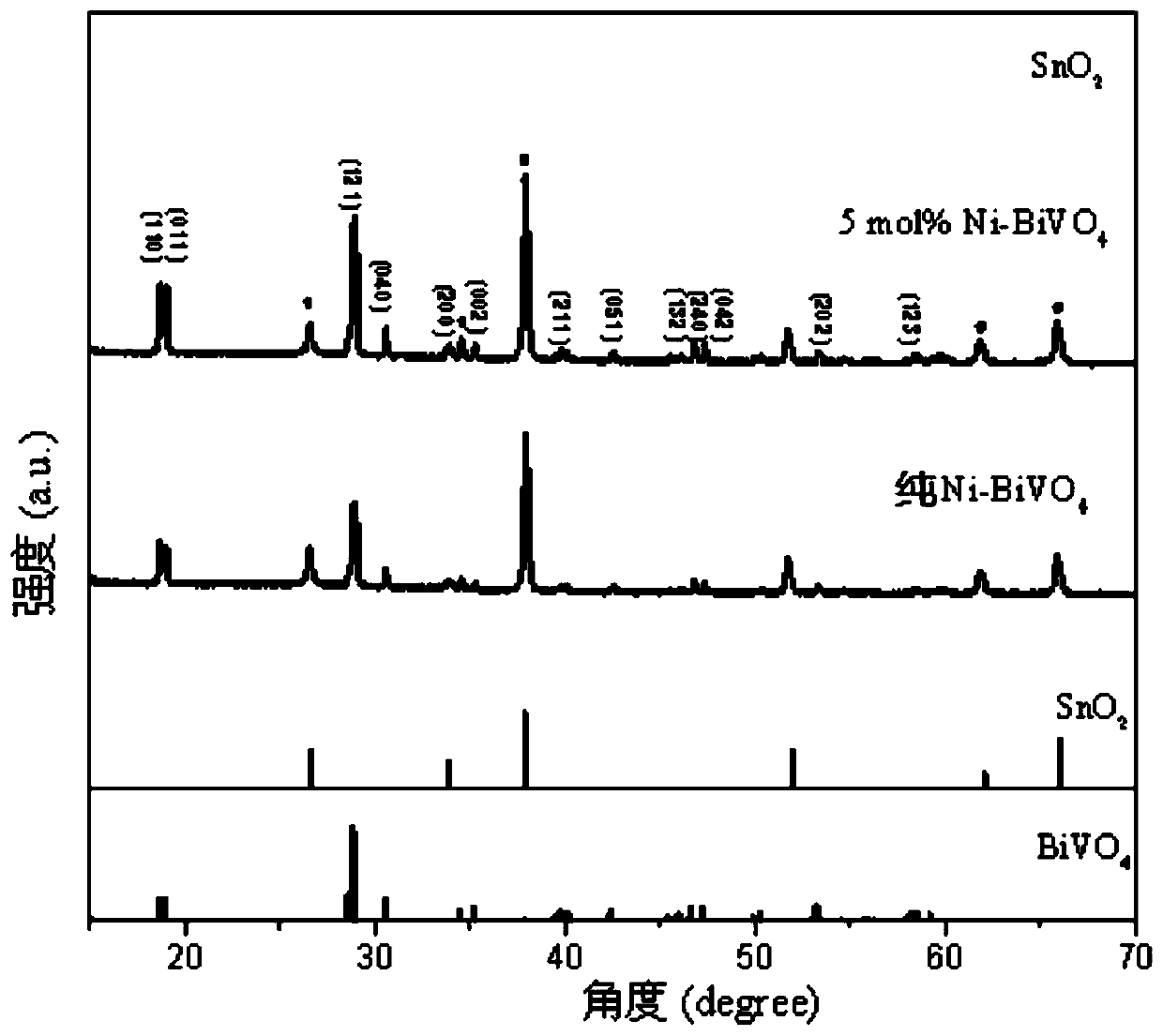

Method used

Image

Examples

Embodiment 1

[0036] (1) Add 3.32g potassium iodide to 50mL deionized water, stir until fully dissolved, add concentrated nitric acid (65wt%) dropwise to the solution, and adjust the pH value to 1.7;

[0037] (2) Set the molar ratio of nickel and bismuth in the solution to be 5:100. Weigh 0.9702g of bismuth nitrate pentahydrate and 0.0291g of nickel nitrate hexahydrate, add them into the potassium iodide solution, and stir until the solids are completely dissolved.

[0038] (3) Dissolve 0.4968g of p-benzoquinone in 20mL of absolute ethanol, stir and dissolve, pour into the solution obtained in step (2), and continue to stir for 30min;

[0039] (4) Ultrasonic the FTO conductive glass in absolute ethanol and deionized water for 30min respectively, and dry at room temperature; the mixed solution in step (3) is electrodeposited, and the working electrode is FTO conductive glass, which is deposited on the surface of the electrode body A layer of BiOI is obtained; the reference electrode and the...

Embodiment 2

[0050] (1) Add 3.32g potassium iodide to 50mL deionized water, stir until fully dissolved, add concentrated nitric acid (65wt%) dropwise to the solution, and adjust the pH value to 1.7;

[0051] (2) Set the molar ratio of nickel and bismuth in the solution to be 1:100, weigh 0.9702g bismuth nitrate pentahydrate and 0.0058g nickel nitrate hexahydrate, join in the potassium iodide solution of step (1), stir until the solid is completely dissolve.

[0052] (3) Dissolve 0.4968g of p-benzoquinone in 20mL of absolute ethanol, stir and dissolve, pour into the solution obtained in step (2), and continue to stir for 30min;

[0053] (4) Ultrasonic the FTO conductive glass in absolute ethanol and deionized water for 30min respectively, and dry at room temperature; the mixed solution in step (3) is electrodeposited, and the working electrode is FTO conductive glass, which is deposited on the surface of the electrode body A layer of BiOI is obtained; the reference electrode and the counte...

Embodiment 3

[0059] (1) Add 3.32g potassium iodide to 50mL deionized water, stir until fully dissolved, add concentrated nitric acid (65wt%) dropwise to the solution, and adjust the pH value to 1.7;

[0060] (2) Set the molar ratio of nickel and bismuth in the solution to be 3:100. Weigh 0.9702g of bismuth nitrate pentahydrate and 0.0174g of nickel nitrate hexahydrate, add them into the potassium iodide solution, and stir until the solids are completely dissolved.

[0061] (3) Dissolve 0.4968g of p-benzoquinone in 20mL of absolute ethanol, stir and dissolve, pour into the solution obtained in step (2), and continue to stir for 30min;

[0062] (4) Ultrasonic the FTO conductive glass in absolute ethanol and deionized water for 30min respectively, and dry at room temperature; the mixed solution in step (3) is electrodeposited, and the working electrode is FTO conductive glass, which is deposited on the surface of the electrode body A layer of BiOI is obtained; the reference electrode and the...

PUM

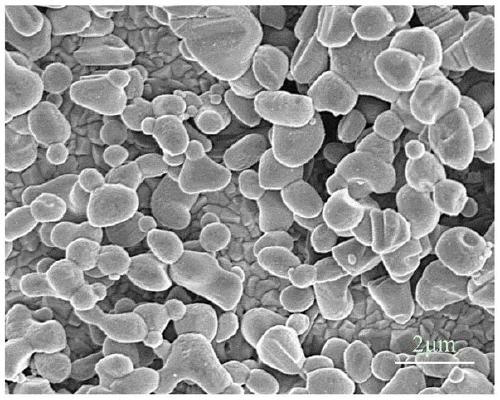

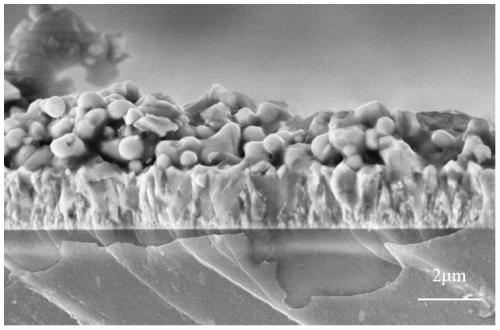

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com